The Industrial Internet integrates advanced sensors, data analytics, and connectivity to optimize manufacturing processes through real-time monitoring and predictive maintenance. Industrial Robotics focuses on programmable machines designed for automation, improving precision, efficiency, and safety in production lines. Explore the distinct advantages and applications of both technologies to enhance modern manufacturing strategies.

Why it is important

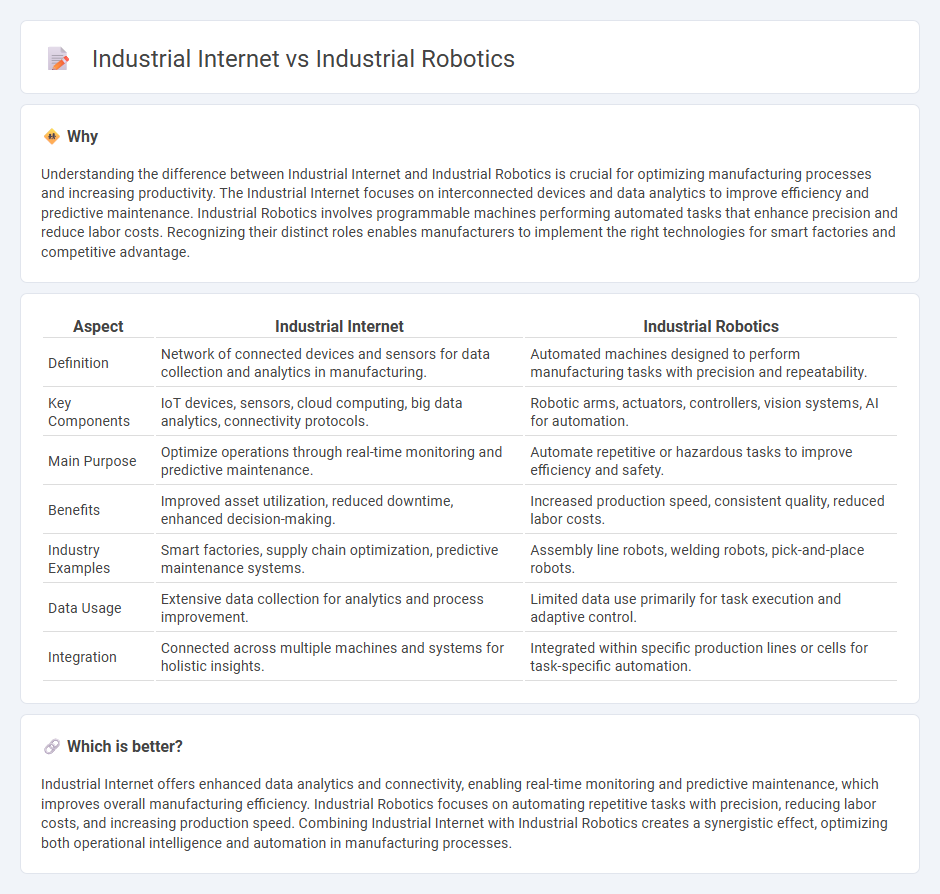

Understanding the difference between Industrial Internet and Industrial Robotics is crucial for optimizing manufacturing processes and increasing productivity. The Industrial Internet focuses on interconnected devices and data analytics to improve efficiency and predictive maintenance. Industrial Robotics involves programmable machines performing automated tasks that enhance precision and reduce labor costs. Recognizing their distinct roles enables manufacturers to implement the right technologies for smart factories and competitive advantage.

Comparison Table

| Aspect | Industrial Internet | Industrial Robotics |

|---|---|---|

| Definition | Network of connected devices and sensors for data collection and analytics in manufacturing. | Automated machines designed to perform manufacturing tasks with precision and repeatability. |

| Key Components | IoT devices, sensors, cloud computing, big data analytics, connectivity protocols. | Robotic arms, actuators, controllers, vision systems, AI for automation. |

| Main Purpose | Optimize operations through real-time monitoring and predictive maintenance. | Automate repetitive or hazardous tasks to improve efficiency and safety. |

| Benefits | Improved asset utilization, reduced downtime, enhanced decision-making. | Increased production speed, consistent quality, reduced labor costs. |

| Industry Examples | Smart factories, supply chain optimization, predictive maintenance systems. | Assembly line robots, welding robots, pick-and-place robots. |

| Data Usage | Extensive data collection for analytics and process improvement. | Limited data use primarily for task execution and adaptive control. |

| Integration | Connected across multiple machines and systems for holistic insights. | Integrated within specific production lines or cells for task-specific automation. |

Which is better?

Industrial Internet offers enhanced data analytics and connectivity, enabling real-time monitoring and predictive maintenance, which improves overall manufacturing efficiency. Industrial Robotics focuses on automating repetitive tasks with precision, reducing labor costs, and increasing production speed. Combining Industrial Internet with Industrial Robotics creates a synergistic effect, optimizing both operational intelligence and automation in manufacturing processes.

Connection

Industrial Internet integrates advanced sensors, data analytics, and connectivity within manufacturing systems to enhance real-time monitoring and predictive maintenance. Industrial Robotics leverages this connectivity to improve automation, precision, and efficiency on the production line by enabling machines to communicate and adapt based on data insights. Together, these technologies drive smart factories, reducing downtime, optimizing workflows, and increasing overall manufacturing productivity.

Key Terms

Automation

Industrial robotics involves the use of programmable machines to perform repetitive tasks with high precision, enhancing manufacturing efficiency and product quality. The industrial internet integrates IoT devices and data analytics to enable real-time monitoring, predictive maintenance, and smarter automation processes. Explore how combining these technologies drives innovation and transforms modern industrial automation.

Connectivity

Industrial robotics emphasize precision and automation in manufacturing processes, driven by robotic arms, sensors, and real-time control systems. The industrial internet focuses on enhanced connectivity and data exchange through IoT devices, cloud computing, and smart analytics to optimize machinery and supply chains. Explore how integrating industrial robotics with the industrial internet transforms connectivity and operational efficiency in modern industries.

Data Analytics

Industrial robotics generates massive operational data through sensors and machine interactions, enabling real-time performance optimization and predictive maintenance. Industrial Internet harnesses this data via cloud computing and IoT platforms, facilitating advanced analytics for enhanced decision-making and supply chain efficiency. Explore how data analytics transforms manufacturing by integrating robotics and internet technologies for smarter industrial processes.

Source and External Links

What Are Industrial Robots? | Built In - Industrial robots are automated machines, typically equipped with one or more reprogrammable arms, designed to perform automated manufacturing tasks such as assembly and material handling with high precision, speed, and no breaks, often operating in safety cages due to their size and power.

The IFR's use of the term "industrial robot" is based on the definition ... - Industrial robots are increasingly smart and connected devices integrated within automation systems to optimize manufacturing performance, enable digital twins, and offer flexible deployment models like Robots as a Service.

Industrial robot - Wikipedia - An industrial robot is an automated, programmable system capable of movement on three or more axes, widely used in manufacturing for tasks such as welding, painting, assembly, and packaging, with over 4 million units in operation globally as of 2023.

dowidth.com

dowidth.com