Flexible manufacturing systems (FMS) enhance production agility by allowing quick adaptation to product variations without extensive downtime, while lean manufacturing focuses on minimizing waste and optimizing workflows to achieve cost efficiency. FMS supports customization and rapid changeovers, making it ideal for diverse product lines, whereas lean manufacturing streamlines processes to deliver maximum value with minimal resources. Discover how integrating these methodologies can revolutionize your production strategy.

Why it is important

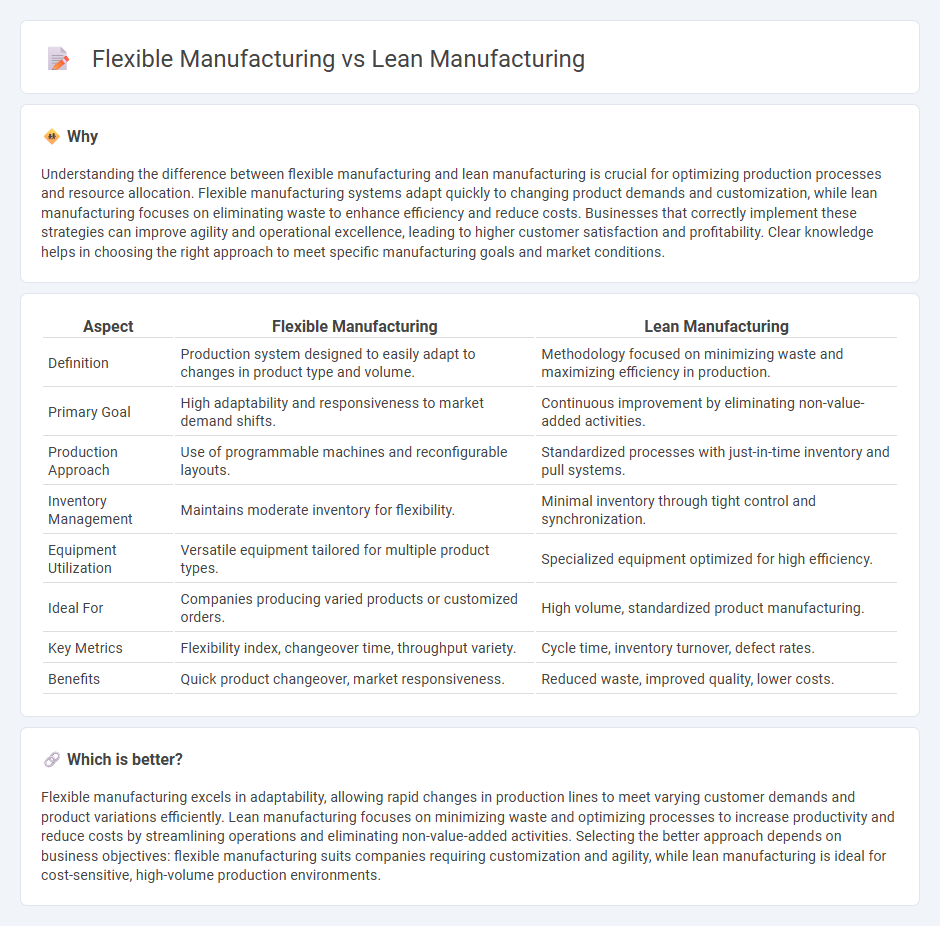

Understanding the difference between flexible manufacturing and lean manufacturing is crucial for optimizing production processes and resource allocation. Flexible manufacturing systems adapt quickly to changing product demands and customization, while lean manufacturing focuses on eliminating waste to enhance efficiency and reduce costs. Businesses that correctly implement these strategies can improve agility and operational excellence, leading to higher customer satisfaction and profitability. Clear knowledge helps in choosing the right approach to meet specific manufacturing goals and market conditions.

Comparison Table

| Aspect | Flexible Manufacturing | Lean Manufacturing |

|---|---|---|

| Definition | Production system designed to easily adapt to changes in product type and volume. | Methodology focused on minimizing waste and maximizing efficiency in production. |

| Primary Goal | High adaptability and responsiveness to market demand shifts. | Continuous improvement by eliminating non-value-added activities. |

| Production Approach | Use of programmable machines and reconfigurable layouts. | Standardized processes with just-in-time inventory and pull systems. |

| Inventory Management | Maintains moderate inventory for flexibility. | Minimal inventory through tight control and synchronization. |

| Equipment Utilization | Versatile equipment tailored for multiple product types. | Specialized equipment optimized for high efficiency. |

| Ideal For | Companies producing varied products or customized orders. | High volume, standardized product manufacturing. |

| Key Metrics | Flexibility index, changeover time, throughput variety. | Cycle time, inventory turnover, defect rates. |

| Benefits | Quick product changeover, market responsiveness. | Reduced waste, improved quality, lower costs. |

Which is better?

Flexible manufacturing excels in adaptability, allowing rapid changes in production lines to meet varying customer demands and product variations efficiently. Lean manufacturing focuses on minimizing waste and optimizing processes to increase productivity and reduce costs by streamlining operations and eliminating non-value-added activities. Selecting the better approach depends on business objectives: flexible manufacturing suits companies requiring customization and agility, while lean manufacturing is ideal for cost-sensitive, high-volume production environments.

Connection

Flexible manufacturing enhances lean manufacturing by enabling rapid adaptation to product changes and minimizing waste through efficient resource utilization. Both systems emphasize continuous flow, reduced inventory, and quick changeovers to increase responsiveness and cost-efficiency in production processes. Integrating flexible manufacturing techniques supports lean principles by fostering agility and eliminating non-value-added activities across manufacturing operations.

Key Terms

Lean Manufacturing: Waste Reduction, Value Stream Mapping, Just-In-Time (JIT)

Lean manufacturing emphasizes waste reduction by systematically identifying and eliminating non-value-added activities within production processes. Value Stream Mapping (VSM) serves as a critical tool to visualize material and information flow, enabling the optimization of each step to enhance efficiency. Explore the principles and applications of Lean Manufacturing to improve operational performance and reduce costs.

Flexible Manufacturing: Reconfigurability, Automation, Modular Systems

Flexible manufacturing emphasizes reconfigurability through modular systems that allow quick adaptation to varying product designs and production volumes, enhancing operational agility. Automation plays a critical role by integrating robotics and intelligent control systems that optimize efficiency and reduce human error. Explore the advantages of flexible manufacturing systems to improve responsiveness and competitiveness in dynamic markets.

**Lean Manufacturing:**

Lean manufacturing emphasizes minimizing waste and enhancing efficiency by streamlining production processes, reducing inventory, and improving quality control. It relies on continuous improvement (Kaizen) and just-in-time (JIT) production to optimize resource utilization and meet customer demand precisely. Discover how lean manufacturing can transform your operations by exploring its core principles and applications.

Source and External Links

Understanding a New Manufacturing System - Lean manufacturing is a production system that emphasizes worker participation, multi-tasking teams, quality control, lower inventory, and continuous improvement, originating from Toyota's approach in the 1950s.

Lean manufacturing - Wikipedia - Lean manufacturing is a methodology aimed at reducing production times and waste through just-in-time delivery, continuous improvement, and elimination of seven key wastes identified by Toyota's production system.

What is Lean Manufacturing? | Definition from TechTarget - Lean manufacturing focuses on minimizing waste and maximizing productivity by implementing principles like Kaizen, with origins in Toyota's Production System and applications beyond manufacturing.

dowidth.com

dowidth.com