Factory as a Service (FaaS) offers scalable, on-demand manufacturing capacity by outsourcing production to specialized third-party providers, emphasizing flexibility and digital integration. Lean manufacturing focuses on eliminating waste and optimizing processes within a company's own facilities to enhance efficiency and reduce costs. Explore the advantages and challenges of both strategies to determine the best fit for your production needs.

Why it is important

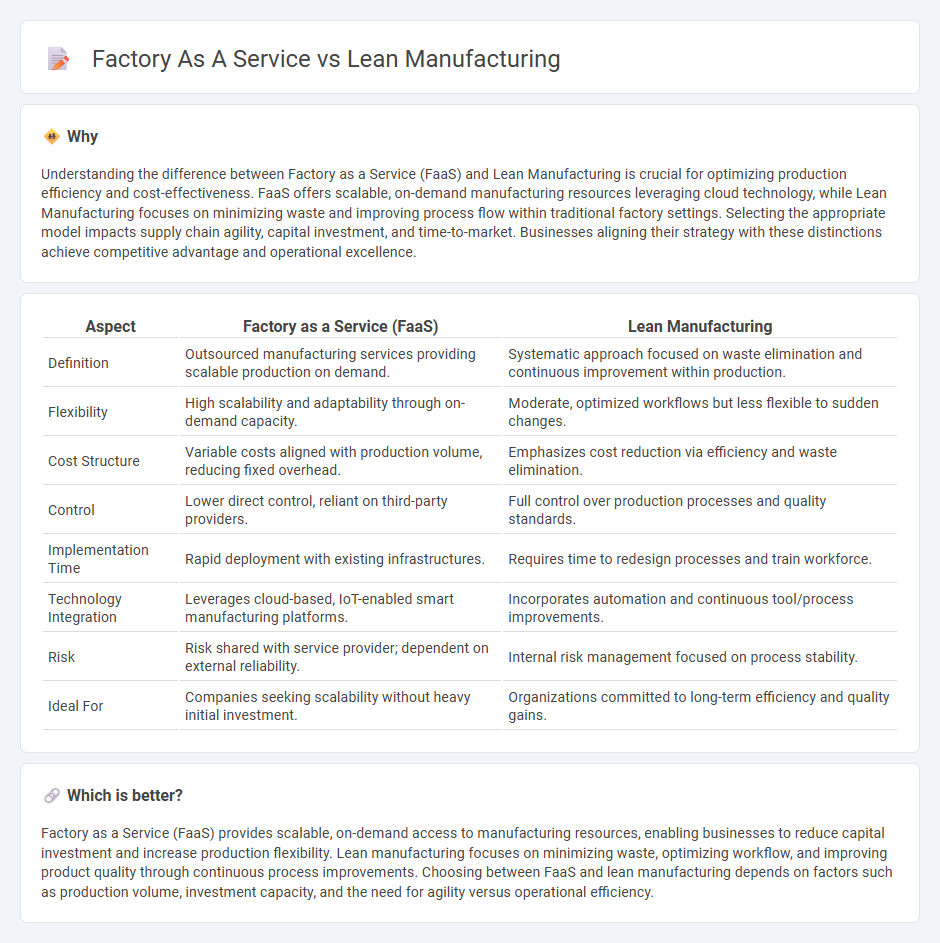

Understanding the difference between Factory as a Service (FaaS) and Lean Manufacturing is crucial for optimizing production efficiency and cost-effectiveness. FaaS offers scalable, on-demand manufacturing resources leveraging cloud technology, while Lean Manufacturing focuses on minimizing waste and improving process flow within traditional factory settings. Selecting the appropriate model impacts supply chain agility, capital investment, and time-to-market. Businesses aligning their strategy with these distinctions achieve competitive advantage and operational excellence.

Comparison Table

| Aspect | Factory as a Service (FaaS) | Lean Manufacturing |

|---|---|---|

| Definition | Outsourced manufacturing services providing scalable production on demand. | Systematic approach focused on waste elimination and continuous improvement within production. |

| Flexibility | High scalability and adaptability through on-demand capacity. | Moderate, optimized workflows but less flexible to sudden changes. |

| Cost Structure | Variable costs aligned with production volume, reducing fixed overhead. | Emphasizes cost reduction via efficiency and waste elimination. |

| Control | Lower direct control, reliant on third-party providers. | Full control over production processes and quality standards. |

| Implementation Time | Rapid deployment with existing infrastructures. | Requires time to redesign processes and train workforce. |

| Technology Integration | Leverages cloud-based, IoT-enabled smart manufacturing platforms. | Incorporates automation and continuous tool/process improvements. |

| Risk | Risk shared with service provider; dependent on external reliability. | Internal risk management focused on process stability. |

| Ideal For | Companies seeking scalability without heavy initial investment. | Organizations committed to long-term efficiency and quality gains. |

Which is better?

Factory as a Service (FaaS) provides scalable, on-demand access to manufacturing resources, enabling businesses to reduce capital investment and increase production flexibility. Lean manufacturing focuses on minimizing waste, optimizing workflow, and improving product quality through continuous process improvements. Choosing between FaaS and lean manufacturing depends on factors such as production volume, investment capacity, and the need for agility versus operational efficiency.

Connection

Factory as a Service (FaaS) integrates seamlessly with lean manufacturing by providing on-demand access to flexible production resources that minimize waste and enhance efficiency. Lean manufacturing principles focus on streamlining workflows, reducing inventory, and eliminating non-value-added activities, which FaaS supports through scalable, technology-driven factory solutions. This synergy enables manufacturers to optimize operational costs, accelerate production cycles, and respond dynamically to market demands without heavy capital investment.

Key Terms

**Lean Manufacturing:**

Lean Manufacturing emphasizes waste reduction, continuous improvement, and maximizing value by streamlining production processes and eliminating inefficiencies. It integrates techniques like Just-In-Time inventory, Kaizen, and Six Sigma to enhance productivity and reduce costs within the manufacturing environment. Explore how Lean Manufacturing transforms operational efficiency and drives competitive advantage in modern production systems.

Waste Reduction

Lean manufacturing minimizes waste through continuous improvement, value stream mapping, and just-in-time production, targeting efficiency in material, time, and labor. Factory as a Service (FaaS) offers flexible, on-demand manufacturing capabilities that reduce waste by optimizing resource allocation and scaling production precisely to demand. Explore how both approaches can transform your production waste management strategies.

Continuous Improvement (Kaizen)

Lean manufacturing emphasizes Continuous Improvement (Kaizen) by systematically identifying and eliminating waste through employee involvement and iterative problem-solving, resulting in enhanced operational efficiency and product quality. Factory as a Service integrates Kaizen principles within flexible, on-demand manufacturing environments, leveraging real-time data and scalable resources to continuously optimize production processes. Explore how adopting Continuous Improvement in these models can drive sustainable growth and operational excellence.

Source and External Links

Lean manufacturing - Lean manufacturing is a method focused on reducing production times and supplier response, rooted in Toyota Production System principles that eliminate non-value activities and seven types of waste such as overproduction and defective products.

What is Lean Manufacturing? | Definition from TechTarget - Lean manufacturing minimizes waste and maximizes productivity by delivering only what customers want, with benefits including reduced lead times, costs, and improved quality, based on principles like Kaizen and the Toyota Production System.

What is Lean Manufacturing and the 5 Principles Used? - TWI - Lean manufacturing maximizes productivity while minimizing waste through five core principles: value, value stream, flow, pull, and perfection, aiming to do more with less effort, time, and resources to meet customer needs precisely.

dowidth.com

dowidth.com