Closed-loop manufacturing integrates real-time data feedback to continuously optimize production processes, enhancing quality control and reducing waste. Discrete manufacturing focuses on producing distinct items in separate units or batches, emphasizing precision and repeatability in assembly lines. Explore the advantages and applications of each manufacturing method to determine the best fit for your operations.

Why it is important

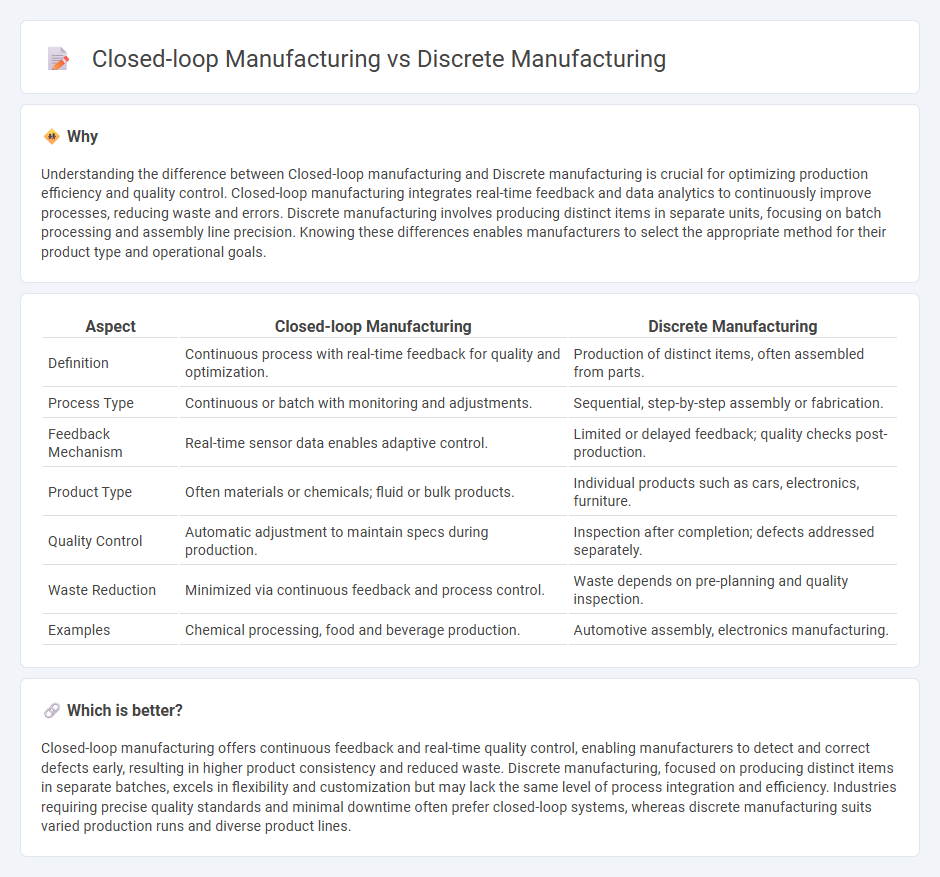

Understanding the difference between Closed-loop manufacturing and Discrete manufacturing is crucial for optimizing production efficiency and quality control. Closed-loop manufacturing integrates real-time feedback and data analytics to continuously improve processes, reducing waste and errors. Discrete manufacturing involves producing distinct items in separate units, focusing on batch processing and assembly line precision. Knowing these differences enables manufacturers to select the appropriate method for their product type and operational goals.

Comparison Table

| Aspect | Closed-loop Manufacturing | Discrete Manufacturing |

|---|---|---|

| Definition | Continuous process with real-time feedback for quality and optimization. | Production of distinct items, often assembled from parts. |

| Process Type | Continuous or batch with monitoring and adjustments. | Sequential, step-by-step assembly or fabrication. |

| Feedback Mechanism | Real-time sensor data enables adaptive control. | Limited or delayed feedback; quality checks post-production. |

| Product Type | Often materials or chemicals; fluid or bulk products. | Individual products such as cars, electronics, furniture. |

| Quality Control | Automatic adjustment to maintain specs during production. | Inspection after completion; defects addressed separately. |

| Waste Reduction | Minimized via continuous feedback and process control. | Waste depends on pre-planning and quality inspection. |

| Examples | Chemical processing, food and beverage production. | Automotive assembly, electronics manufacturing. |

Which is better?

Closed-loop manufacturing offers continuous feedback and real-time quality control, enabling manufacturers to detect and correct defects early, resulting in higher product consistency and reduced waste. Discrete manufacturing, focused on producing distinct items in separate batches, excels in flexibility and customization but may lack the same level of process integration and efficiency. Industries requiring precise quality standards and minimal downtime often prefer closed-loop systems, whereas discrete manufacturing suits varied production runs and diverse product lines.

Connection

Closed-loop manufacturing integrates real-time feedback from production processes to continuously improve discrete manufacturing operations, enhancing accuracy and reducing waste. By utilizing sensor data and automated controls, closed-loop systems enable discrete manufacturing to adjust parameters swiftly, optimizing product quality and efficiency. This synergy supports agile production workflows, minimizing errors and ensuring consistent output in complex manufacturing environments.

Key Terms

Bill of Materials (BOM)

Discrete manufacturing manages production through separate, distinct units often relying on a static Bill of Materials (BOM) that details individual components and assemblies. Closed-loop manufacturing integrates real-time feedback and data from production processes to continuously update and optimize the BOM, enhancing accuracy in material requirements and reducing waste. Explore how adapting your BOM strategy can improve efficiency and responsiveness in your manufacturing operations.

Feedback Control Systems

Discrete manufacturing involves producing distinct items like cars or electronics through sequential processes, whereas closed-loop manufacturing integrates continuous feedback control systems to monitor and adjust operations in real time, enhancing precision and reducing defects. Feedback control systems typically employ sensors, controllers, and actuators to maintain desired performance by automatically correcting deviations during production. Discover more about how feedback control systems revolutionize manufacturing efficiency and quality management.

Traceability

Discrete manufacturing involves producing distinct items like cars or electronics, focusing on tracking individual components through each production stage for quality control. Closed-loop manufacturing integrates real-time feedback and data analytics to continuously improve processes and ensure precise traceability from raw materials to finished goods. Explore how advanced traceability systems enhance efficiency and compliance in both manufacturing types.

Source and External Links

Discrete manufacturing - Wikipedia - Discrete manufacturing is the production of distinct, countable items such as automobiles, furniture, and smartphones, characterized by separate unit production and variable inputs, differing from continuous process manufacturing like oil or salt production.

Discrete Manufacturing - Oracle Help Center - Discrete manufacturing involves work orders producing specific quantities of single items, with independent operations in routing, and is used in environments like make-to-stock, make-to-order, and assemble-to-order for products such as cars and electronics.

5 Detailed Examples of Discrete Manufacturing - shoplogix - Key benefits of discrete manufacturing include efficiency from automation, quality control through individual assembly, and flexibility to adapt product designs and customer demand changes.

dowidth.com

dowidth.com