Cobots enhance manufacturing efficiency by collaborating with human workers on complex tasks, improving precision and safety in assembly lines. 3D printers revolutionize production through rapid prototyping and custom part fabrication, significantly reducing lead times and material waste. Explore how integrating cobots and 3D printing can transform your manufacturing processes.

Why it is important

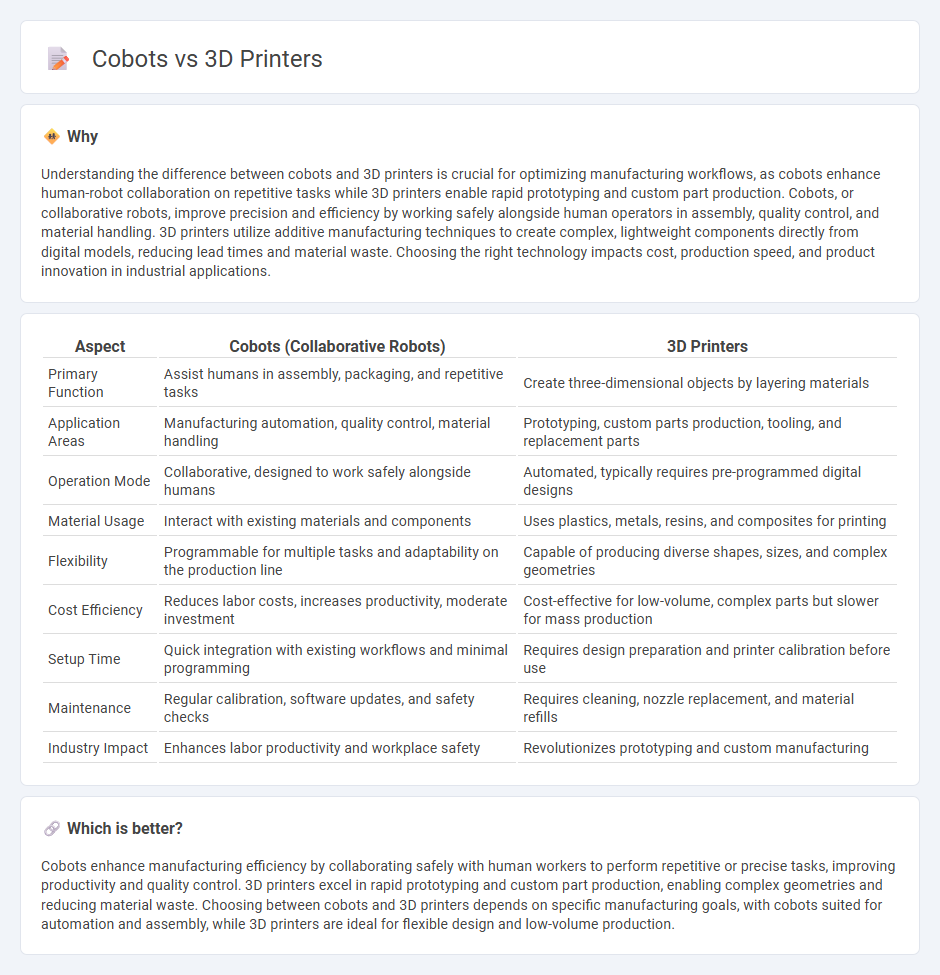

Understanding the difference between cobots and 3D printers is crucial for optimizing manufacturing workflows, as cobots enhance human-robot collaboration on repetitive tasks while 3D printers enable rapid prototyping and custom part production. Cobots, or collaborative robots, improve precision and efficiency by working safely alongside human operators in assembly, quality control, and material handling. 3D printers utilize additive manufacturing techniques to create complex, lightweight components directly from digital models, reducing lead times and material waste. Choosing the right technology impacts cost, production speed, and product innovation in industrial applications.

Comparison Table

| Aspect | Cobots (Collaborative Robots) | 3D Printers |

|---|---|---|

| Primary Function | Assist humans in assembly, packaging, and repetitive tasks | Create three-dimensional objects by layering materials |

| Application Areas | Manufacturing automation, quality control, material handling | Prototyping, custom parts production, tooling, and replacement parts |

| Operation Mode | Collaborative, designed to work safely alongside humans | Automated, typically requires pre-programmed digital designs |

| Material Usage | Interact with existing materials and components | Uses plastics, metals, resins, and composites for printing |

| Flexibility | Programmable for multiple tasks and adaptability on the production line | Capable of producing diverse shapes, sizes, and complex geometries |

| Cost Efficiency | Reduces labor costs, increases productivity, moderate investment | Cost-effective for low-volume, complex parts but slower for mass production |

| Setup Time | Quick integration with existing workflows and minimal programming | Requires design preparation and printer calibration before use |

| Maintenance | Regular calibration, software updates, and safety checks | Requires cleaning, nozzle replacement, and material refills |

| Industry Impact | Enhances labor productivity and workplace safety | Revolutionizes prototyping and custom manufacturing |

Which is better?

Cobots enhance manufacturing efficiency by collaborating safely with human workers to perform repetitive or precise tasks, improving productivity and quality control. 3D printers excel in rapid prototyping and custom part production, enabling complex geometries and reducing material waste. Choosing between cobots and 3D printers depends on specific manufacturing goals, with cobots suited for automation and assembly, while 3D printers are ideal for flexible design and low-volume production.

Connection

Cobots enhance manufacturing efficiency by collaborating with human operators, often integrating seamlessly with 3D printers to automate additive manufacturing processes. This synergy enables precise, flexible production of complex parts with reduced lead times and increased customization. Data-driven coordination between cobots and 3D printers optimizes workflow, minimizes errors, and accelerates prototyping in advanced manufacturing sectors.

Key Terms

Additive Manufacturing

3D printers and cobots both play critical roles in additive manufacturing, with 3D printers enabling precise layer-by-layer fabrication of complex geometries using materials such as polymers, metals, and composites. Cobots, or collaborative robots, enhance automation by safely working alongside human operators to streamline post-processing, assembly, and Quality Control tasks in production environments. Explore further how integrating 3D printing with cobots can optimize efficiency and innovation in additive manufacturing workflows.

Collaborative Robotics

Collaborative robots (cobots) enhance manufacturing efficiency by working alongside humans to perform precise, repetitive tasks, offering adaptability and ease of programming beyond what 3D printers can achieve. Unlike 3D printers, which specialize in additive manufacturing for rapid prototyping and small-batch production, cobots integrate seamlessly into diverse workflows to improve productivity and safety. Explore how cobots transform industrial automation and complement additive manufacturing processes to innovate production lines effectively.

Automation

3D printers and cobots (collaborative robots) both play pivotal roles in automation, enhancing manufacturing efficiency through additive production and human-robot collaboration respectively. 3D printers enable rapid prototyping and customization by building complex parts layer-by-layer, while cobots optimize assembly lines by safely working alongside humans, increasing precision and reducing operational downtime. Explore how integrating 3D printing and cobot technologies transforms automated workflows and boosts industrial productivity.

Source and External Links

3D printing - Wikipedia - 3D printing, or additive manufacturing, constructs three-dimensional objects from digital models, enabling rapid prototyping, customization, and complex geometries with high precision while reducing waste and costs.

Original Prusa 3D printers directly from Josef Prusa - The Prusa MK4S is a durable, easily upgradable 3D printer known for reliability and high-quality prints, while the XL model stands out for advanced multi-material and multi-extruder capabilities.

Creality - Official Website - Creality offers a range of user-friendly 3D printers like the Ender-3 V3, S1, and K2 Plus, praised for their speed, print quality, and accessibility for both beginners and professionals.

dowidth.com

dowidth.com