Industrial Internet integrates advanced connectivity and data analytics to transform manufacturing processes, enabling real-time decision-making and predictive maintenance. Industrial Automation focuses on mechanizing production through robotics and control systems to enhance efficiency and reduce human error. Explore the evolving landscape of manufacturing by understanding how these technologies reshape industrial operations.

Why it is important

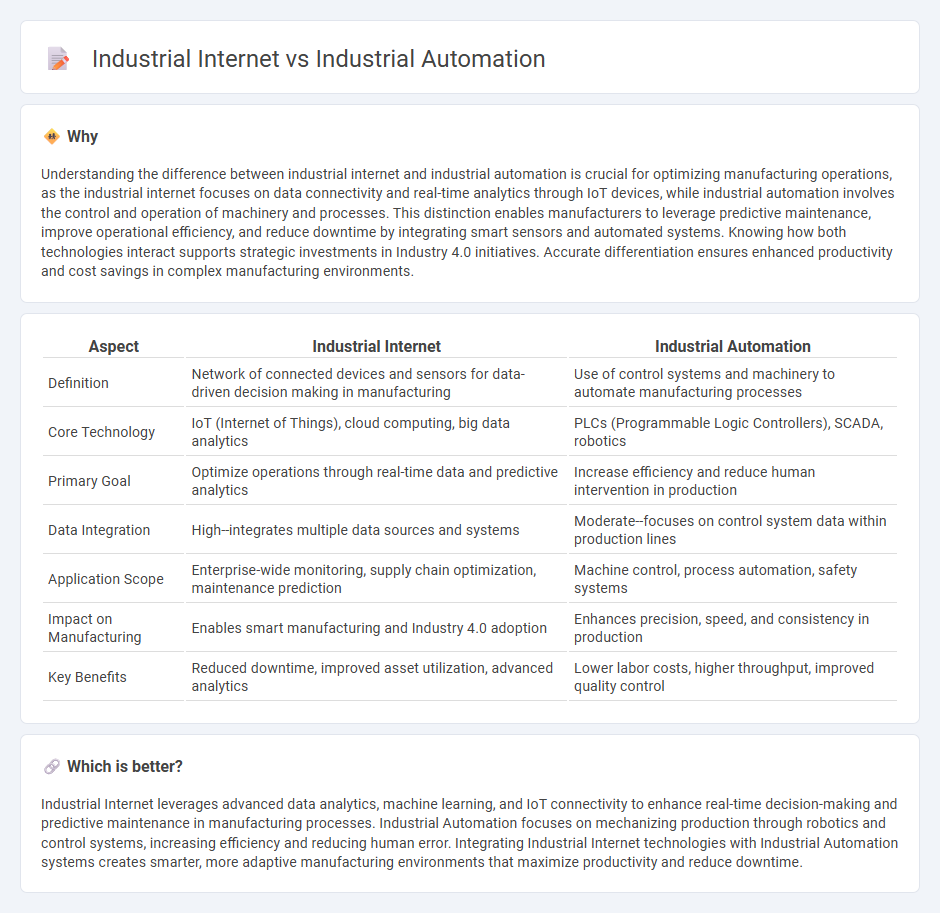

Understanding the difference between industrial internet and industrial automation is crucial for optimizing manufacturing operations, as the industrial internet focuses on data connectivity and real-time analytics through IoT devices, while industrial automation involves the control and operation of machinery and processes. This distinction enables manufacturers to leverage predictive maintenance, improve operational efficiency, and reduce downtime by integrating smart sensors and automated systems. Knowing how both technologies interact supports strategic investments in Industry 4.0 initiatives. Accurate differentiation ensures enhanced productivity and cost savings in complex manufacturing environments.

Comparison Table

| Aspect | Industrial Internet | Industrial Automation |

|---|---|---|

| Definition | Network of connected devices and sensors for data-driven decision making in manufacturing | Use of control systems and machinery to automate manufacturing processes |

| Core Technology | IoT (Internet of Things), cloud computing, big data analytics | PLCs (Programmable Logic Controllers), SCADA, robotics |

| Primary Goal | Optimize operations through real-time data and predictive analytics | Increase efficiency and reduce human intervention in production |

| Data Integration | High--integrates multiple data sources and systems | Moderate--focuses on control system data within production lines |

| Application Scope | Enterprise-wide monitoring, supply chain optimization, maintenance prediction | Machine control, process automation, safety systems |

| Impact on Manufacturing | Enables smart manufacturing and Industry 4.0 adoption | Enhances precision, speed, and consistency in production |

| Key Benefits | Reduced downtime, improved asset utilization, advanced analytics | Lower labor costs, higher throughput, improved quality control |

Which is better?

Industrial Internet leverages advanced data analytics, machine learning, and IoT connectivity to enhance real-time decision-making and predictive maintenance in manufacturing processes. Industrial Automation focuses on mechanizing production through robotics and control systems, increasing efficiency and reducing human error. Integrating Industrial Internet technologies with Industrial Automation systems creates smarter, more adaptive manufacturing environments that maximize productivity and reduce downtime.

Connection

Industrial Internet integrates smart sensors and IoT devices to collect real-time data from manufacturing equipment, enabling enhanced monitoring and predictive maintenance. Industrial Automation utilizes this data to control and optimize machinery operations, reducing human intervention and increasing efficiency. The synergy between Industrial Internet and Industrial Automation drives intelligent manufacturing processes, resulting in improved productivity, reduced downtime, and cost savings.

Key Terms

Robotics

Industrial automation employs robotics to streamline manufacturing processes by integrating programmable machines and control systems for enhanced efficiency and precision. The industrial internet connects these robotics through IoT sensors and cloud computing, enabling real-time data analysis and predictive maintenance for optimized performance. Explore how robotics transform industries by combining automation and the industrial internet for smarter, more autonomous operations.

IoT (Internet of Things)

Industrial automation integrates control systems, such as PLCs and SCADA, to streamline manufacturing processes and improve efficiency. The Industrial Internet leverages IoT devices and sensors to connect machines and systems, enabling real-time data analytics, predictive maintenance, and enhanced decision-making. Explore how IoT transforms industrial operations through increased connectivity and intelligence.

SCADA

Industrial automation integrates SCADA systems to monitor and control manufacturing processes, enhancing efficiency and reducing human intervention. The industrial internet leverages SCADA by connecting these systems to the cloud, enabling real-time data analytics and predictive maintenance through IoT devices. Explore how SCADA bridges traditional automation with the industrial internet for smarter manufacturing solutions.

dowidth.com

dowidth.com