Machine vision systems utilize cameras and image processing to inspect and analyze products, offering high-speed, non-contact measurement ideal for complex shapes and surface defects. Laser measurement employs focused laser beams to capture precise dimensional data, providing exceptional accuracy for distance, thickness, and profile measurements in manufacturing environments. Explore the advantages and applications of machine vision and laser measurement technologies to enhance production quality and efficiency.

Why it is important

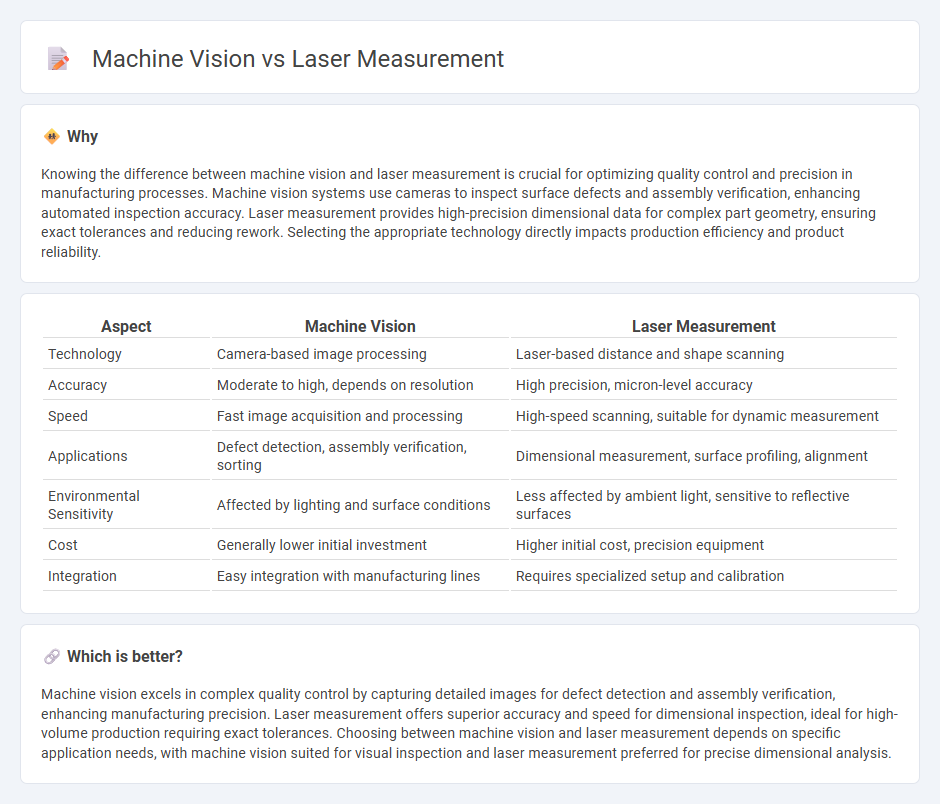

Knowing the difference between machine vision and laser measurement is crucial for optimizing quality control and precision in manufacturing processes. Machine vision systems use cameras to inspect surface defects and assembly verification, enhancing automated inspection accuracy. Laser measurement provides high-precision dimensional data for complex part geometry, ensuring exact tolerances and reducing rework. Selecting the appropriate technology directly impacts production efficiency and product reliability.

Comparison Table

| Aspect | Machine Vision | Laser Measurement |

|---|---|---|

| Technology | Camera-based image processing | Laser-based distance and shape scanning |

| Accuracy | Moderate to high, depends on resolution | High precision, micron-level accuracy |

| Speed | Fast image acquisition and processing | High-speed scanning, suitable for dynamic measurement |

| Applications | Defect detection, assembly verification, sorting | Dimensional measurement, surface profiling, alignment |

| Environmental Sensitivity | Affected by lighting and surface conditions | Less affected by ambient light, sensitive to reflective surfaces |

| Cost | Generally lower initial investment | Higher initial cost, precision equipment |

| Integration | Easy integration with manufacturing lines | Requires specialized setup and calibration |

Which is better?

Machine vision excels in complex quality control by capturing detailed images for defect detection and assembly verification, enhancing manufacturing precision. Laser measurement offers superior accuracy and speed for dimensional inspection, ideal for high-volume production requiring exact tolerances. Choosing between machine vision and laser measurement depends on specific application needs, with machine vision suited for visual inspection and laser measurement preferred for precise dimensional analysis.

Connection

Machine vision systems utilize cameras and image processing algorithms to inspect and analyze manufactured parts, while laser measurement provides precise dimensional data through laser scanning and triangulation techniques. Integration of these technologies enables real-time quality control by combining visual defect detection with accurate geometric measurements. This synergy enhances manufacturing efficiency by reducing errors and ensuring adherence to strict tolerances.

Key Terms

Precision

Laser measurement systems offer unparalleled precision by emitting focused light beams that accurately gauge distances and surface profiles with micron-level accuracy. Machine vision relies on high-resolution cameras and image processing algorithms to analyze visual data, excelling in pattern recognition but usually with lower precision compared to laser techniques. Explore the technical specifications and use cases to understand which method best suits your precision requirements.

Imaging

Laser measurement offers high precision in distance and surface profiling by emitting a focused laser beam and capturing its reflection, ideal for dimensional accuracy in industrial applications. Machine vision relies on imaging sensors and cameras to capture and analyze visual information, enabling complex object recognition, defect detection, and assembly verification. Explore more about how these imaging technologies optimize quality control and automation in manufacturing processes.

Non-contact detection

Laser measurement offers precise non-contact detection by utilizing focused beams to capture accurate distance and dimensional data, ideal for high-accuracy industrial applications. Machine vision employs cameras and image processing algorithms to analyze surfaces and identify defects without physical contact, supporting complex inspection tasks and real-time automation. Discover how integrating laser measurement and machine vision can enhance non-contact detection systems for diverse manufacturing needs.

Source and External Links

After Testing These 9 Laser Measures, Our Top Pick is a Must-Have - Laser measures use a laser and optical sensor to determine the distance between two surfaces, typically offering accuracy within 1/8 inch at 50 feet, with some models reaching up to 320 feet and higher precision for increased cost.

Laser Distance Measurer - Best Laser Measurement Tools | Fluke - Handheld laser distance meters provide fast, high-precision measurements, are safe for hazardous or hard-to-reach areas, and outperform traditional tape measures in accuracy and convenience.

Laser Measures - Bosch Power Tools - Bosch laser measures offer precise distance measurement from 100 to 400 feet, are available with green or red lasers, and are built to withstand tough job site conditions with high durability ratings.

dowidth.com

dowidth.com