Microfactories emphasize compact, localized production with flexible manufacturing units capable of rapid customization and reduced lead times, often integrating multiple processes in a single facility. Additive manufacturing centers focus on advanced 3D printing technologies, enabling the creation of complex geometries and lightweight parts with minimal material waste and digital design scalability. Explore the latest innovations and benefits in manufacturing by delving deeper into microfactories and additive manufacturing centers.

Why it is important

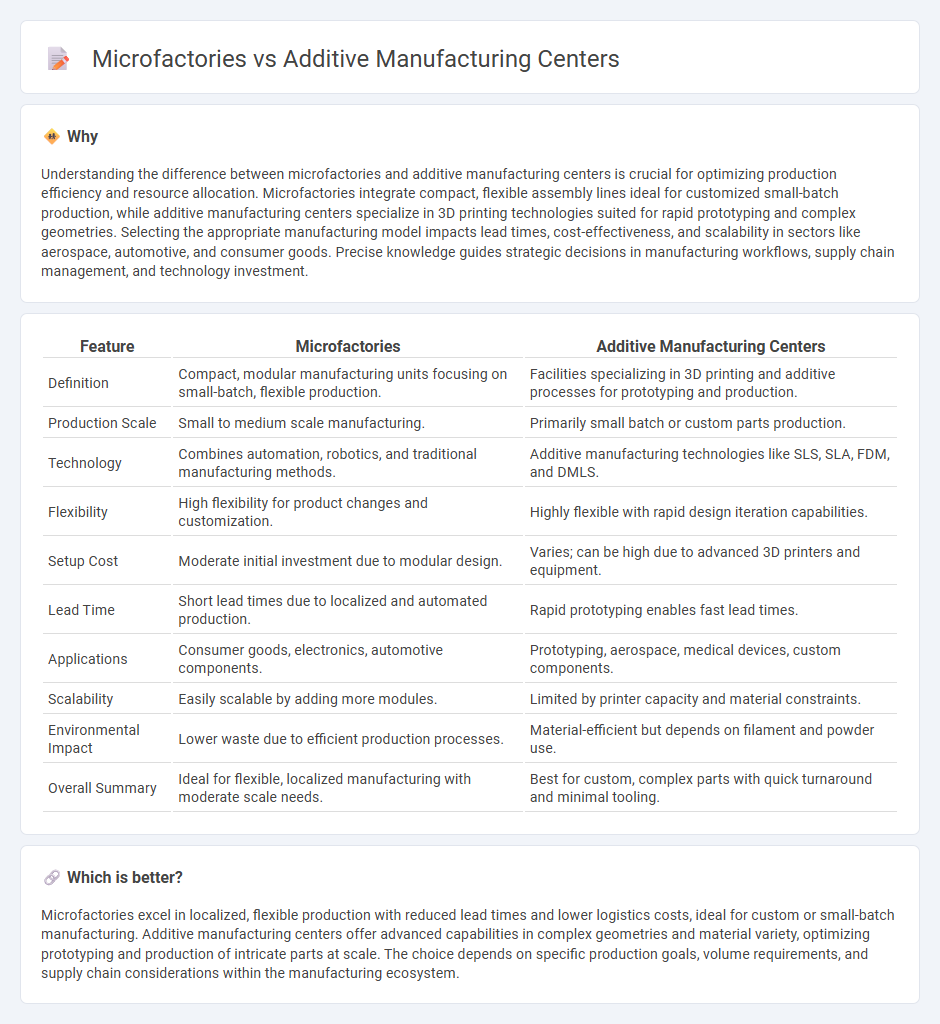

Understanding the difference between microfactories and additive manufacturing centers is crucial for optimizing production efficiency and resource allocation. Microfactories integrate compact, flexible assembly lines ideal for customized small-batch production, while additive manufacturing centers specialize in 3D printing technologies suited for rapid prototyping and complex geometries. Selecting the appropriate manufacturing model impacts lead times, cost-effectiveness, and scalability in sectors like aerospace, automotive, and consumer goods. Precise knowledge guides strategic decisions in manufacturing workflows, supply chain management, and technology investment.

Comparison Table

| Feature | Microfactories | Additive Manufacturing Centers |

|---|---|---|

| Definition | Compact, modular manufacturing units focusing on small-batch, flexible production. | Facilities specializing in 3D printing and additive processes for prototyping and production. |

| Production Scale | Small to medium scale manufacturing. | Primarily small batch or custom parts production. |

| Technology | Combines automation, robotics, and traditional manufacturing methods. | Additive manufacturing technologies like SLS, SLA, FDM, and DMLS. |

| Flexibility | High flexibility for product changes and customization. | Highly flexible with rapid design iteration capabilities. |

| Setup Cost | Moderate initial investment due to modular design. | Varies; can be high due to advanced 3D printers and equipment. |

| Lead Time | Short lead times due to localized and automated production. | Rapid prototyping enables fast lead times. |

| Applications | Consumer goods, electronics, automotive components. | Prototyping, aerospace, medical devices, custom components. |

| Scalability | Easily scalable by adding more modules. | Limited by printer capacity and material constraints. |

| Environmental Impact | Lower waste due to efficient production processes. | Material-efficient but depends on filament and powder use. |

| Overall Summary | Ideal for flexible, localized manufacturing with moderate scale needs. | Best for custom, complex parts with quick turnaround and minimal tooling. |

Which is better?

Microfactories excel in localized, flexible production with reduced lead times and lower logistics costs, ideal for custom or small-batch manufacturing. Additive manufacturing centers offer advanced capabilities in complex geometries and material variety, optimizing prototyping and production of intricate parts at scale. The choice depends on specific production goals, volume requirements, and supply chain considerations within the manufacturing ecosystem.

Connection

Microfactories and additive manufacturing centers both revolutionize production by enabling localized, flexible, and on-demand manufacturing processes. Microfactories integrate additive manufacturing technologies such as 3D printing to rapidly prototype and produce complex parts with minimal waste and lower inventory costs. This synergy enhances supply chain resilience, reduces lead times, and supports mass customization in modern manufacturing ecosystems.

Key Terms

Production Scale

Additive manufacturing centers typically handle large-scale production using industrial-grade 3D printers that enable batch manufacturing and high throughput for sectors like aerospace and automotive. Microfactories focus on localized, small-batch production with flexible manufacturing lines that emphasize customization, speed, and lower capital investment, making them ideal for rapid prototyping and niche product markets. Explore the distinct advantages of both models to determine the best fit for your production scale needs.

Flexibility

Additive manufacturing centers offer centralized production with scalability and advanced customization capabilities, while microfactories provide localized, highly flexible manufacturing tailored to rapid market changes and small batch production. The modular design of microfactories supports quick reconfiguration and adaptive processes, ideal for businesses requiring agile responses to demand variability. Explore more about how these manufacturing models can transform your production strategy.

Equipment Size

Additive manufacturing centers typically house large-scale industrial 3D printers designed for high-volume production, while microfactories utilize compact, modular equipment that enables flexible, localized manufacturing. Equipment size in microfactories promotes scalability and rapid reconfiguration, ideal for customized or small-batch production. Explore deeper insights into how equipment size impacts efficiency and production capabilities in these innovative manufacturing models.

Source and External Links

Additive Manufacturing Pittsburgh - This webpage highlights Pittsburgh as a hub for American additive manufacturing, featuring industry leaders and educational institutions like Carnegie Mellon University and the University of Pittsburgh.

Additive Manufacturing Center of Excellence - The U.S. Navy's Additive Manufacturing Center of Excellence is a collaborative project that develops advanced manufacturing technical data packages for military parts.

MIT Center for Advanced Production Technologies (APT) - APT at MIT focuses on advancing additive manufacturing through research, process innovation, and workforce training, offering collaboration with industry partners.

dowidth.com

dowidth.com