Zero Defect Manufacturing focuses on producing products with zero faults by implementing strict quality control measures throughout the production process. Kaizen emphasizes continuous incremental improvements involving all employees to enhance efficiency and reduce errors over time. Explore the distinct strategies and benefits of Zero Defect Manufacturing and Kaizen to optimize your manufacturing operations.

Why it is important

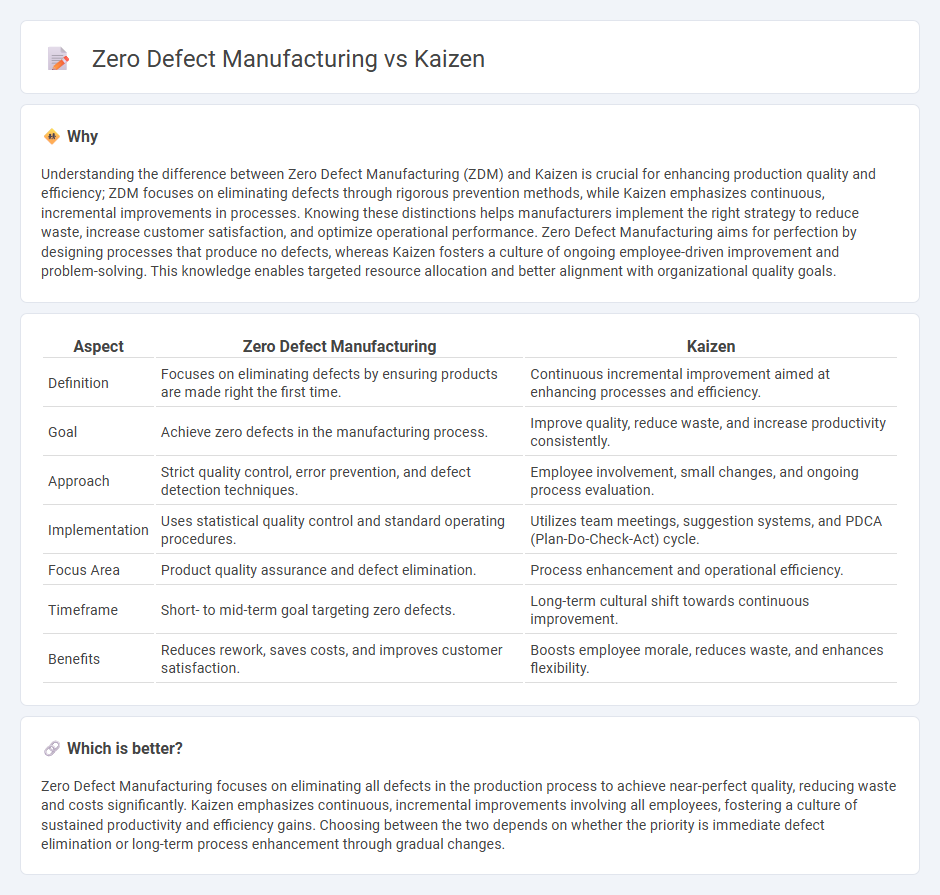

Understanding the difference between Zero Defect Manufacturing (ZDM) and Kaizen is crucial for enhancing production quality and efficiency; ZDM focuses on eliminating defects through rigorous prevention methods, while Kaizen emphasizes continuous, incremental improvements in processes. Knowing these distinctions helps manufacturers implement the right strategy to reduce waste, increase customer satisfaction, and optimize operational performance. Zero Defect Manufacturing aims for perfection by designing processes that produce no defects, whereas Kaizen fosters a culture of ongoing employee-driven improvement and problem-solving. This knowledge enables targeted resource allocation and better alignment with organizational quality goals.

Comparison Table

| Aspect | Zero Defect Manufacturing | Kaizen |

|---|---|---|

| Definition | Focuses on eliminating defects by ensuring products are made right the first time. | Continuous incremental improvement aimed at enhancing processes and efficiency. |

| Goal | Achieve zero defects in the manufacturing process. | Improve quality, reduce waste, and increase productivity consistently. |

| Approach | Strict quality control, error prevention, and defect detection techniques. | Employee involvement, small changes, and ongoing process evaluation. |

| Implementation | Uses statistical quality control and standard operating procedures. | Utilizes team meetings, suggestion systems, and PDCA (Plan-Do-Check-Act) cycle. |

| Focus Area | Product quality assurance and defect elimination. | Process enhancement and operational efficiency. |

| Timeframe | Short- to mid-term goal targeting zero defects. | Long-term cultural shift towards continuous improvement. |

| Benefits | Reduces rework, saves costs, and improves customer satisfaction. | Boosts employee morale, reduces waste, and enhances flexibility. |

Which is better?

Zero Defect Manufacturing focuses on eliminating all defects in the production process to achieve near-perfect quality, reducing waste and costs significantly. Kaizen emphasizes continuous, incremental improvements involving all employees, fostering a culture of sustained productivity and efficiency gains. Choosing between the two depends on whether the priority is immediate defect elimination or long-term process enhancement through gradual changes.

Connection

Zero defect manufacturing (ZDM) and Kaizen are interconnected through their shared focus on continuous improvement in production processes to minimize defects and enhance quality. Kaizen's incremental, employee-driven improvements support the ZDM goal by systematically identifying and eliminating sources of errors and inefficiencies. Implementing Kaizen practices fosters a culture of quality awareness, directly contributing to achieving zero defect objectives in manufacturing operations.

Key Terms

Continuous Improvement (Kaizen)

Kaizen emphasizes continuous improvement through small, incremental changes involving all employees to enhance processes, quality, and efficiency over time. Zero Defect Manufacturing aims to eliminate defects entirely by focusing on stringent quality control and error prevention methodologies. Discover how integrating both philosophies can transform industrial performance by clicking here.

Poka-Yoke (Zero Defect)

Kaizen emphasizes continuous incremental improvements in manufacturing processes to enhance efficiency and quality, while Zero Defect manufacturing aims to eliminate defects entirely through preventive measures like Poka-Yoke, which are error-proofing techniques designed to detect and prevent mistakes at the source. Poka-Yoke devices help in maintaining consistent product quality by automatically identifying errors before they escalate, fostering a culture of defect-free production. To explore how integrating Kaizen with Poka-Yoke can transform your manufacturing quality, delve deeper into advanced Zero Defect strategies.

Employee Involvement

Kaizen emphasizes continuous employee involvement by encouraging workers at all levels to contribute ideas for incremental improvements, fostering a culture of collaboration and empowerment. Zero Defect Manufacturing centers on employee responsibility to prevent defects through stringent quality control and adherence to standardized processes, promoting accountability and precision. Explore how integrating both approaches can maximize workforce engagement and production excellence.

Source and External Links

Kaizen - Wikipedia - Kaizen is a Japanese business concept meaning "improvement," focusing on continuous, small incremental improvements across all company operations involving every employee, aiming to eliminate waste and redundancies, and it is rooted in post-WWII Japanese industry practices including the Toyota Production System.

Kaizen: Culture of Continuous Improvement | Lean Production - Kaizen is both a strategy and philosophy where all employees collaborate to make regular incremental improvements, often using the PDCA (Plan, Do, Check, Act) cycle to continuously improve processes and develop a culture of ongoing improvement in manufacturing and other operations.

Kaizen -- A Resource Guide | Lean Enterprise Institute - Kaizen means continuous improvement through small incremental changes, typically implemented via PDCA cycles and kaizen events, with a strong focus on reducing waste of time, materials, and resources to improve efficiency and quality.

dowidth.com

dowidth.com