Digital thread creates a seamless flow of data across the entire product lifecycle, enabling real-time visibility and traceability from design to production and beyond. CIM (Computer Integrated Manufacturing) integrates automated systems and machines to optimize manufacturing processes, focusing on efficiency and reducing manual intervention. Explore the differences and benefits of Digital Thread versus CIM to enhance your manufacturing strategy.

Why it is important

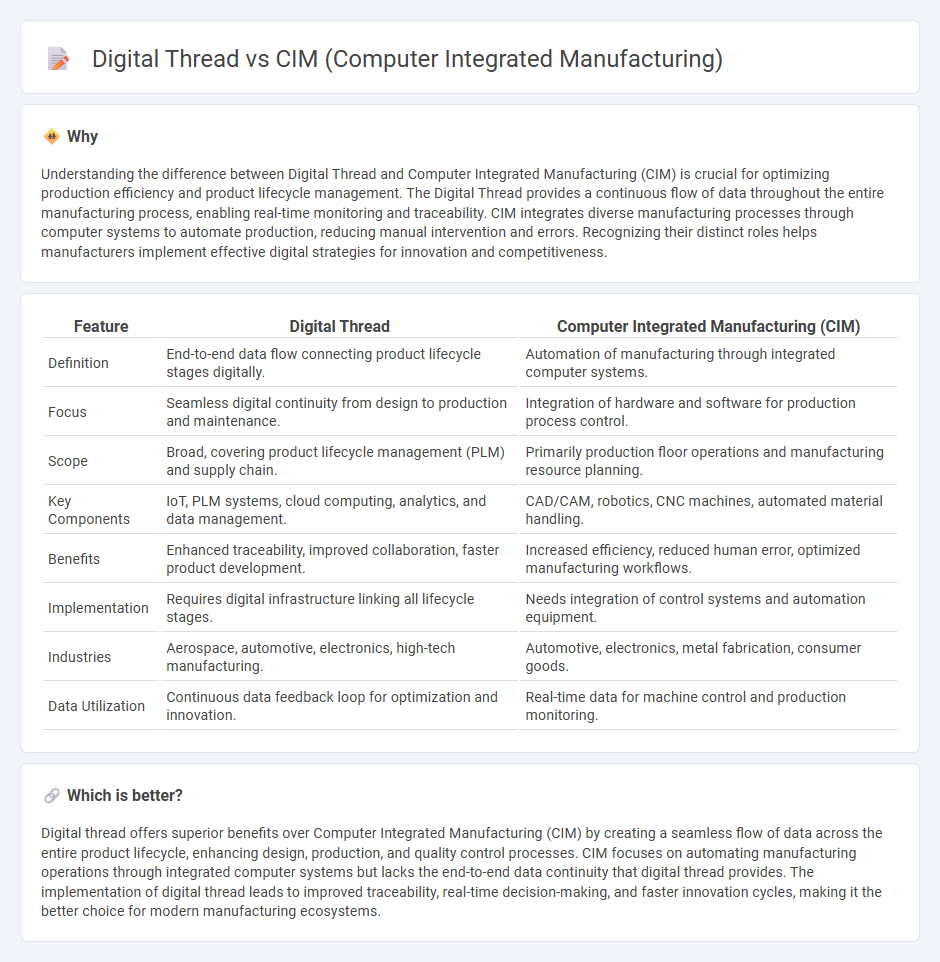

Understanding the difference between Digital Thread and Computer Integrated Manufacturing (CIM) is crucial for optimizing production efficiency and product lifecycle management. The Digital Thread provides a continuous flow of data throughout the entire manufacturing process, enabling real-time monitoring and traceability. CIM integrates diverse manufacturing processes through computer systems to automate production, reducing manual intervention and errors. Recognizing their distinct roles helps manufacturers implement effective digital strategies for innovation and competitiveness.

Comparison Table

| Feature | Digital Thread | Computer Integrated Manufacturing (CIM) |

|---|---|---|

| Definition | End-to-end data flow connecting product lifecycle stages digitally. | Automation of manufacturing through integrated computer systems. |

| Focus | Seamless digital continuity from design to production and maintenance. | Integration of hardware and software for production process control. |

| Scope | Broad, covering product lifecycle management (PLM) and supply chain. | Primarily production floor operations and manufacturing resource planning. |

| Key Components | IoT, PLM systems, cloud computing, analytics, and data management. | CAD/CAM, robotics, CNC machines, automated material handling. |

| Benefits | Enhanced traceability, improved collaboration, faster product development. | Increased efficiency, reduced human error, optimized manufacturing workflows. |

| Implementation | Requires digital infrastructure linking all lifecycle stages. | Needs integration of control systems and automation equipment. |

| Industries | Aerospace, automotive, electronics, high-tech manufacturing. | Automotive, electronics, metal fabrication, consumer goods. |

| Data Utilization | Continuous data feedback loop for optimization and innovation. | Real-time data for machine control and production monitoring. |

Which is better?

Digital thread offers superior benefits over Computer Integrated Manufacturing (CIM) by creating a seamless flow of data across the entire product lifecycle, enhancing design, production, and quality control processes. CIM focuses on automating manufacturing operations through integrated computer systems but lacks the end-to-end data continuity that digital thread provides. The implementation of digital thread leads to improved traceability, real-time decision-making, and faster innovation cycles, making it the better choice for modern manufacturing ecosystems.

Connection

Digital thread technology integrates data flow across product lifecycle stages, enabling continuous feedback and real-time monitoring in manufacturing processes. CIM (Computer Integrated Manufacturing) leverages this interconnected data to automate production, optimize resource allocation, and enhance process efficiency. The synergy between digital thread and CIM drives smart manufacturing by linking design, production, and quality control into a seamless, data-driven ecosystem.

Key Terms

CIM:

Computer Integrated Manufacturing (CIM) streamlines production by integrating various manufacturing processes through computer systems, enhancing automation, efficiency, and real-time data management across design, planning, and production stages. Unlike the digital thread, which connects data and processes across the entire product lifecycle, CIM specifically focuses on optimizing factory floor operations and manufacturing workflows. Explore more to understand how CIM revolutionizes industrial automation and drives smart manufacturing.

Automation

Computer Integrated Manufacturing (CIM) automates production processes by integrating various manufacturing systems through centralized control, optimizing workflow and reducing human intervention. The digital thread creates a continuous, real-time data flow across the product lifecycle, enabling seamless automation in design, manufacturing, and maintenance phases. Explore how these automation frameworks drive efficiency and innovation in modern manufacturing systems.

Integration

Computer Integrated Manufacturing (CIM) centralizes manufacturing processes through automated data exchange among machines, enhancing production efficiency and reducing errors. The digital thread extends integration by creating a continuous data flow across product lifecycle stages, linking design, manufacturing, and service information for holistic visibility and optimization. Explore how leveraging CIM and the digital thread together drives smarter, more connected manufacturing ecosystems.

Source and External Links

Computer-Integrated Manufacturing (CIM): Automation & Efficiency - CIM is a manufacturing method where the entire production process is controlled by computers, integrating all operations around a centralized data system to improve efficiency, quality, and flexibility by enabling information exchange across all manufacturing processes.

Computer-integrated manufacturing - Wikipedia - CIM uses computers to control all aspects of the production process, linking various functions such as design, planning, inventory, and factory floor operations to achieve faster, less error-prone manufacturing through real-time data exchange and closed-loop control.

Understanding Computer Integrated Manufacturing (CIM) Meaning - CIM automates and streamlines the entire manufacturing process from design to finished product by integrating CAD, CAM, CNC machines, and PLCs, enhancing production efficiency, accuracy, and quality across industries.

dowidth.com

dowidth.com