Lights-out manufacturing operates with fully automated production lines running without human intervention, maximizing efficiency and reducing labor costs. Just-in-time manufacturing emphasizes minimizing inventory by producing goods only as needed, improving cash flow and reducing waste. Explore the differences between these methods to determine the optimal approach for your manufacturing needs.

Why it is important

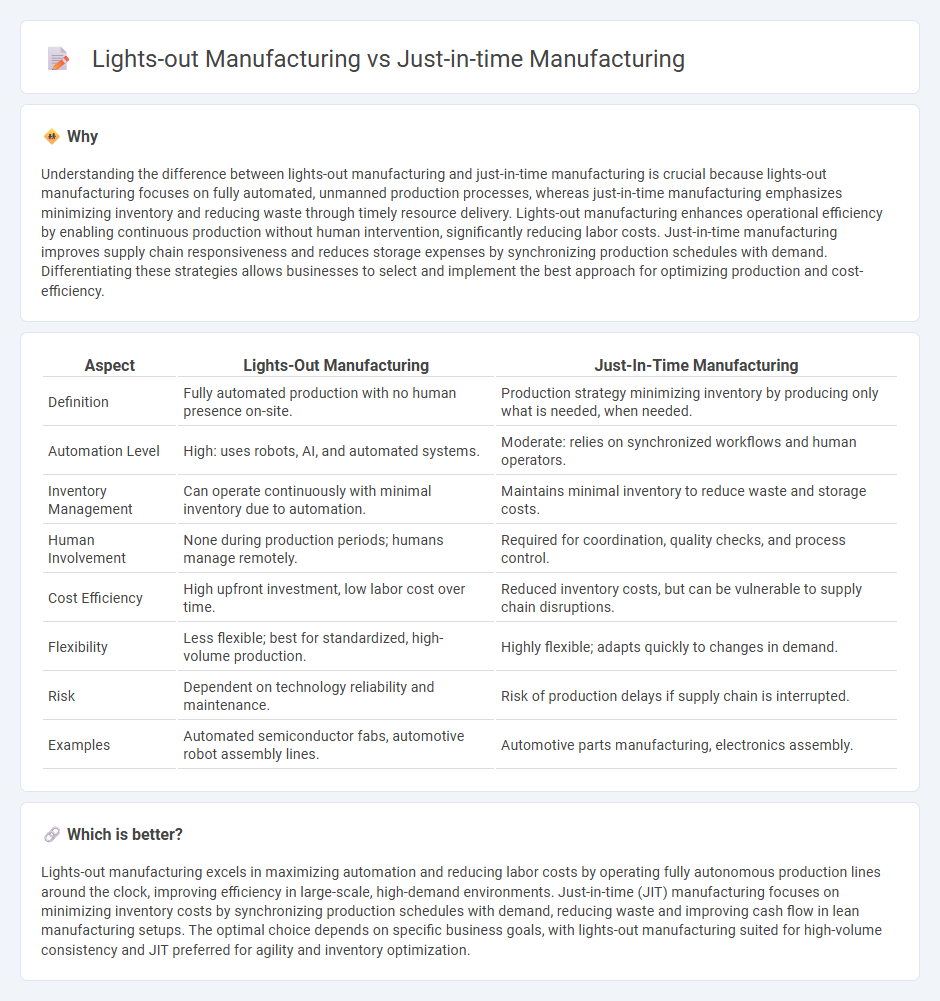

Understanding the difference between lights-out manufacturing and just-in-time manufacturing is crucial because lights-out manufacturing focuses on fully automated, unmanned production processes, whereas just-in-time manufacturing emphasizes minimizing inventory and reducing waste through timely resource delivery. Lights-out manufacturing enhances operational efficiency by enabling continuous production without human intervention, significantly reducing labor costs. Just-in-time manufacturing improves supply chain responsiveness and reduces storage expenses by synchronizing production schedules with demand. Differentiating these strategies allows businesses to select and implement the best approach for optimizing production and cost-efficiency.

Comparison Table

| Aspect | Lights-Out Manufacturing | Just-In-Time Manufacturing |

|---|---|---|

| Definition | Fully automated production with no human presence on-site. | Production strategy minimizing inventory by producing only what is needed, when needed. |

| Automation Level | High: uses robots, AI, and automated systems. | Moderate: relies on synchronized workflows and human operators. |

| Inventory Management | Can operate continuously with minimal inventory due to automation. | Maintains minimal inventory to reduce waste and storage costs. |

| Human Involvement | None during production periods; humans manage remotely. | Required for coordination, quality checks, and process control. |

| Cost Efficiency | High upfront investment, low labor cost over time. | Reduced inventory costs, but can be vulnerable to supply chain disruptions. |

| Flexibility | Less flexible; best for standardized, high-volume production. | Highly flexible; adapts quickly to changes in demand. |

| Risk | Dependent on technology reliability and maintenance. | Risk of production delays if supply chain is interrupted. |

| Examples | Automated semiconductor fabs, automotive robot assembly lines. | Automotive parts manufacturing, electronics assembly. |

Which is better?

Lights-out manufacturing excels in maximizing automation and reducing labor costs by operating fully autonomous production lines around the clock, improving efficiency in large-scale, high-demand environments. Just-in-time (JIT) manufacturing focuses on minimizing inventory costs by synchronizing production schedules with demand, reducing waste and improving cash flow in lean manufacturing setups. The optimal choice depends on specific business goals, with lights-out manufacturing suited for high-volume consistency and JIT preferred for agility and inventory optimization.

Connection

Lights-out manufacturing relies heavily on just-in-time manufacturing principles to minimize inventory and reduce waste by synchronizing production schedules with demand. Automated systems in lights-out factories enable precise timing and rapid adjustments, ensuring components arrive exactly when needed to maintain continuous, unattended operation. This integration enhances efficiency, lowers costs, and improves responsiveness across the manufacturing supply chain.

Key Terms

Inventory Management

Just-in-time manufacturing minimizes inventory levels by synchronizing production with demand, reducing storage costs and waste. Lights-out manufacturing automates production processes to operate without human intervention, allowing continuous operation and precise inventory control through advanced robotics and AI systems. Explore key differences and benefits in inventory management between these innovative manufacturing approaches.

Automation

Just-in-time manufacturing minimizes inventory by synchronizing production with demand, while lights-out manufacturing fully automates processes to run without human intervention, significantly boosting efficiency. Automation in just-in-time manufacturing focuses on real-time data integration and flexible machinery, whereas lights-out manufacturing relies on advanced robotics and AI to operate continuously. Explore how these automation strategies transform manufacturing workflows and productivity.

Human Labor

Just-in-time manufacturing emphasizes minimizing inventory and relies heavily on skilled human labor to ensure precise timing and quality control throughout production processes. Lights-out manufacturing aims for fully automated, unmanned factories where machines operate continuously without human intervention, drastically reducing labor costs and human error. Explore how these distinct approaches impact workforce dynamics and operational efficiency in modern manufacturing.

Source and External Links

Just In Time Manufacturing: Definition, Benefits, and Origin - JIT manufacturing is a production strategy that minimizes inventory and waste by producing goods only as needed, improving efficiency, reducing lead times, and enhancing quality through continuous monitoring and supplier collaboration.

Just-in-Time Manufacturing (JIT): Definitions, Benefits, Tips - JIT is a methodology that strives to meet customer demand exactly while minimizing waste and costs, relying on accurate demand forecasting and aligning supply directly with production schedules.

What is just-in-time manufacturing (JIT manufacturing)? - JIT manufacturing is a production model where items are created to meet actual demand, not in advance, with the goal of increasing efficiency, reducing costs, and speeding up delivery by eliminating overproduction and unnecessary inventory.

dowidth.com

dowidth.com