Factory as a Service (FaaS) revolutionizes manufacturing by offering scalable, on-demand production capabilities without the need for heavy capital investment, contrasting with traditional Just-in-Time (JIT) manufacturing that emphasizes minimal inventory and rapid response to market demand. FaaS leverages cloud-based platforms and advanced automation to optimize workflow flexibility and reduce lead times, whereas JIT focuses on supply chain efficiency and precise timing of component deliveries. Explore more to understand how these innovative manufacturing models can transform operational efficiency and cost management.

Why it is important

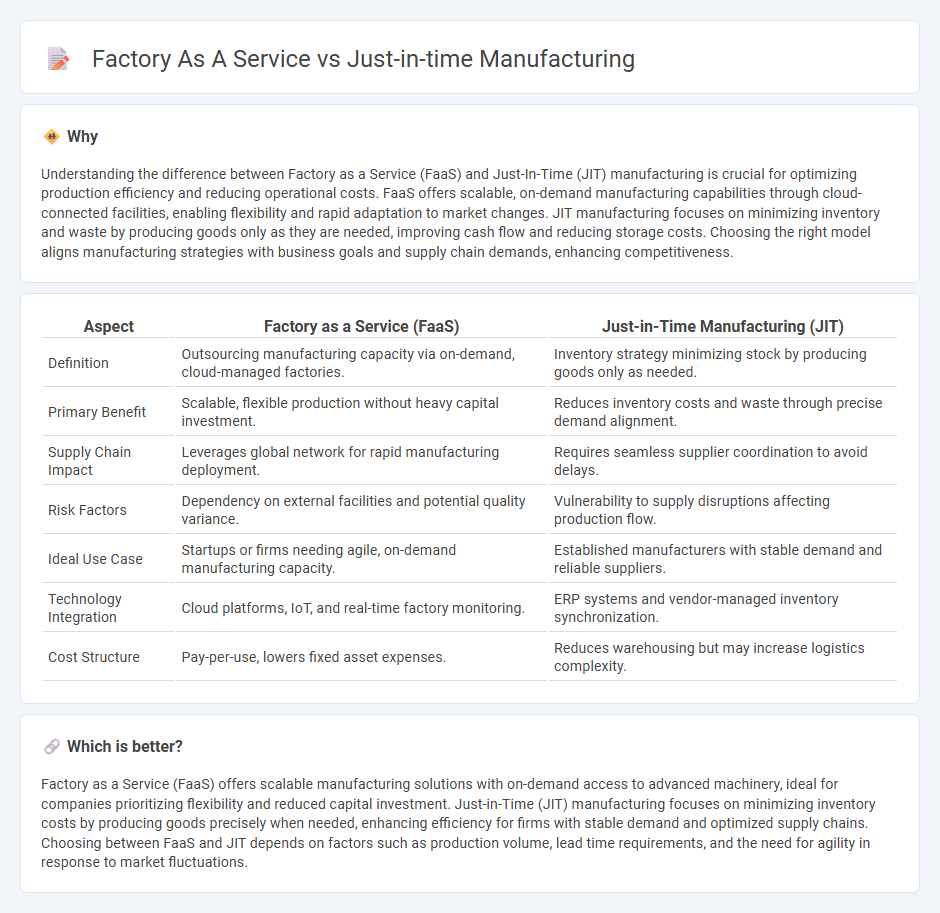

Understanding the difference between Factory as a Service (FaaS) and Just-In-Time (JIT) manufacturing is crucial for optimizing production efficiency and reducing operational costs. FaaS offers scalable, on-demand manufacturing capabilities through cloud-connected facilities, enabling flexibility and rapid adaptation to market changes. JIT manufacturing focuses on minimizing inventory and waste by producing goods only as they are needed, improving cash flow and reducing storage costs. Choosing the right model aligns manufacturing strategies with business goals and supply chain demands, enhancing competitiveness.

Comparison Table

| Aspect | Factory as a Service (FaaS) | Just-in-Time Manufacturing (JIT) |

|---|---|---|

| Definition | Outsourcing manufacturing capacity via on-demand, cloud-managed factories. | Inventory strategy minimizing stock by producing goods only as needed. |

| Primary Benefit | Scalable, flexible production without heavy capital investment. | Reduces inventory costs and waste through precise demand alignment. |

| Supply Chain Impact | Leverages global network for rapid manufacturing deployment. | Requires seamless supplier coordination to avoid delays. |

| Risk Factors | Dependency on external facilities and potential quality variance. | Vulnerability to supply disruptions affecting production flow. |

| Ideal Use Case | Startups or firms needing agile, on-demand manufacturing capacity. | Established manufacturers with stable demand and reliable suppliers. |

| Technology Integration | Cloud platforms, IoT, and real-time factory monitoring. | ERP systems and vendor-managed inventory synchronization. |

| Cost Structure | Pay-per-use, lowers fixed asset expenses. | Reduces warehousing but may increase logistics complexity. |

Which is better?

Factory as a Service (FaaS) offers scalable manufacturing solutions with on-demand access to advanced machinery, ideal for companies prioritizing flexibility and reduced capital investment. Just-in-Time (JIT) manufacturing focuses on minimizing inventory costs by producing goods precisely when needed, enhancing efficiency for firms with stable demand and optimized supply chains. Choosing between FaaS and JIT depends on factors such as production volume, lead time requirements, and the need for agility in response to market fluctuations.

Connection

Factory as a Service (FaaS) streamlines production by providing on-demand manufacturing capabilities that align directly with Just-in-Time (JIT) principles, minimizing inventory and reducing lead times. By leveraging FaaS, companies can access flexible factory resources that adjust to real-time demand, ensuring components and products are produced exactly when needed. This integration enhances supply chain agility, decreases waste, and improves overall operational efficiency in manufacturing processes.

Key Terms

Inventory Management

Just-in-time manufacturing minimizes inventory levels by synchronizing production schedules with demand, reducing holding costs and waste. Factory as a Service integrates flexible cloud-based production resources to dynamically manage inventory across multiple facilities, enhancing scalability and responsiveness. Explore detailed strategies and technologies revolutionizing inventory management in these innovative manufacturing models.

Production Flexibility

Just-in-time manufacturing minimizes inventory by producing goods only as needed, enhancing production flexibility through rapid response to demand fluctuations and reducing waste. Factory as a Service (FaaS) offers scalable, on-demand access to manufacturing capacity, allowing businesses to adjust production volumes and customize processes without long-term commitments or capital investment. Explore how these models impact production agility and operational efficiency to optimize your manufacturing strategy.

Cloud-Based Manufacturing

Just-in-time manufacturing minimizes inventory costs by synchronizing production with demand, leveraging real-time data to optimize supply chain efficiency within traditional factory environments. Factory as a Service (FaaS) transforms manufacturing by offering cloud-based access to flexible, scalable production resources and on-demand equipment, enabling enterprises to reduce capital expenditure and accelerate time-to-market. Explore how cloud-based manufacturing integrates JIT principles with FaaS models to revolutionize operational agility and production responsiveness.

Source and External Links

Just In Time Manufacturing: Definition, Benefits, and Origin - Just in Time manufacturing (JIT) is a production strategy that produces goods based on customer orders to minimize inventory, reduce operational costs, improve efficiency, and enable flexibility in manufacturing while enhancing product quality and supplier relationships.

Lean manufacturing - Wikipedia - Just-in-time manufacturing matches production to demand by supplying goods only as they are ordered, emphasizing efficient workflows, flexible setups, defect elimination, and close supplier networks within a lean production system.

What is just-in-time manufacturing (JIT manufacturing)? - TechTarget - JIT manufacturing is a model that creates items only to meet demand, eliminating waste such as overproduction and excessive inventory to increase efficiency, reduce costs, and speed product delivery.

dowidth.com

dowidth.com