Zero Defect Manufacturing focuses on eliminating defects through rigorous quality control and process optimization, aiming for flawless production outcomes. Just-In-Time Manufacturing emphasizes minimizing inventory and reducing waste by producing goods only as needed, aligning supply closely with demand. Explore how these strategies can transform efficiency and quality in your production processes.

Why it is important

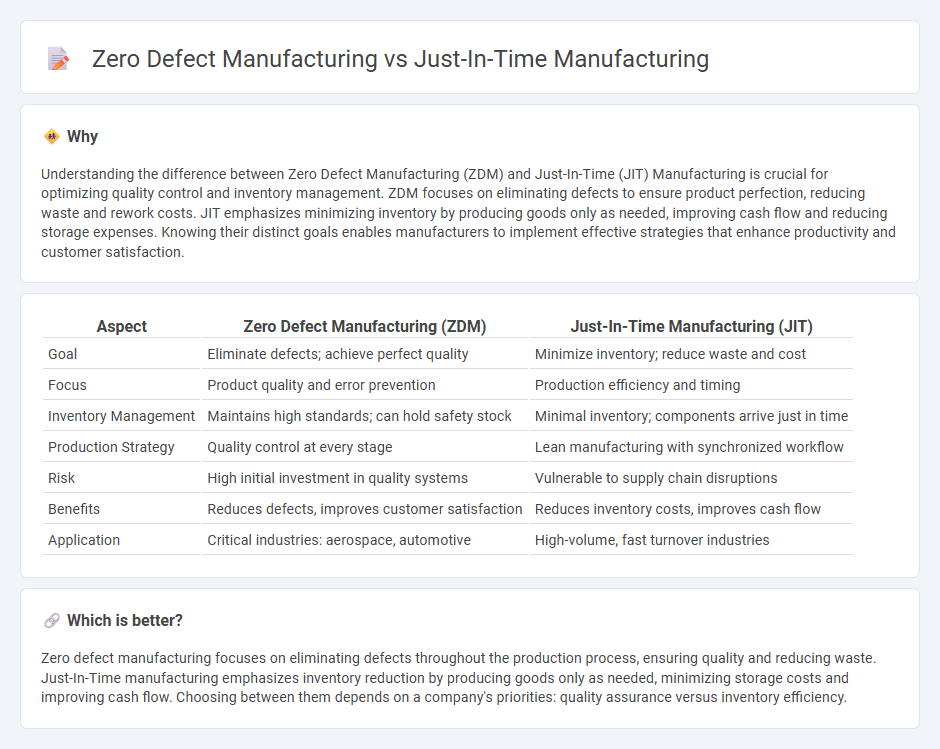

Understanding the difference between Zero Defect Manufacturing (ZDM) and Just-In-Time (JIT) Manufacturing is crucial for optimizing quality control and inventory management. ZDM focuses on eliminating defects to ensure product perfection, reducing waste and rework costs. JIT emphasizes minimizing inventory by producing goods only as needed, improving cash flow and reducing storage expenses. Knowing their distinct goals enables manufacturers to implement effective strategies that enhance productivity and customer satisfaction.

Comparison Table

| Aspect | Zero Defect Manufacturing (ZDM) | Just-In-Time Manufacturing (JIT) |

|---|---|---|

| Goal | Eliminate defects; achieve perfect quality | Minimize inventory; reduce waste and cost |

| Focus | Product quality and error prevention | Production efficiency and timing |

| Inventory Management | Maintains high standards; can hold safety stock | Minimal inventory; components arrive just in time |

| Production Strategy | Quality control at every stage | Lean manufacturing with synchronized workflow |

| Risk | High initial investment in quality systems | Vulnerable to supply chain disruptions |

| Benefits | Reduces defects, improves customer satisfaction | Reduces inventory costs, improves cash flow |

| Application | Critical industries: aerospace, automotive | High-volume, fast turnover industries |

Which is better?

Zero defect manufacturing focuses on eliminating defects throughout the production process, ensuring quality and reducing waste. Just-In-Time manufacturing emphasizes inventory reduction by producing goods only as needed, minimizing storage costs and improving cash flow. Choosing between them depends on a company's priorities: quality assurance versus inventory efficiency.

Connection

Zero Defect Manufacturing (ZDM) and Just-In-Time (JIT) Manufacturing intersect by focusing on minimizing waste and improving efficiency in production processes. ZDM ensures products are made with minimal or no defects, reducing rework and scrap costs, which complements JIT's strategy of producing only what is needed, when it is needed. This synergy enhances overall manufacturing quality and inventory management, leading to cost savings and faster response times.

Key Terms

Inventory Management

Just-In-Time (JIT) Manufacturing minimizes inventory by aligning production closely with demand, reducing carrying costs and storage needs. Zero Defect Manufacturing emphasizes quality control to prevent defects, which can lower inventory waste and rework expenses by ensuring products meet standards from the start. Explore how these strategies optimize inventory management and improve operational efficiency.

Quality Control

Just-In-Time (JIT) manufacturing minimizes inventory and reduces waste by producing goods only as needed, enhancing efficiency but increasing reliance on precise quality control to prevent defects. Zero Defect Manufacturing (ZDM) prioritizes eliminating errors throughout the production process, employing rigorous inspection and continuous improvement to ensure product reliability and customer satisfaction. Explore how integrating JIT and ZDM strategies can optimize quality control and operational excellence.

Waste Reduction

Just-In-Time (JIT) manufacturing minimizes waste by producing goods only as needed, reducing inventory and excess materials, while Zero Defect Manufacturing (ZDM) targets waste elimination through rigorous quality control and defect prevention to ensure products meet perfect standards. Both methodologies significantly enhance operational efficiency and reduce material, time, and cost waste, yet JIT focuses on flow and timing, whereas ZDM emphasizes quality and error-proofing processes. Explore how integrating JIT and ZDM strategies can maximize waste reduction and boost manufacturing performance.

Source and External Links

Just In Time Manufacturing: Definition, Benefits, and Origin - JIT is a production strategy focused on minimizing inventory and waste by producing goods based on customer demand, using standardized operations, a pull system, backward scheduling, and continuous improvement to ensure efficiency and responsiveness.

Lean manufacturing -- Wikipedia - Just-in-time manufacturing matches production to customer orders, emphasizes efficiency and waste reduction, and employs methodologies such as housekeeping, setup reduction, lot sizes of one, uniform plant load, pull systems, and worker involvement to streamline operations.

What is just-in-time manufacturing (JIT manufacturing)? -- TechTarget - JIT manufacturing is a model where items are made only as needed, not in advance, to increase efficiency, reduce costs, speed up delivery, and eliminate waste like overproduction and excessive inventory.

dowidth.com

dowidth.com