Digital twinning leverages virtual models to simulate and analyze manufacturing processes in real time, enabling rapid iteration and optimization without physical material costs. Physical prototyping involves creating tangible models to test functionality and design, providing hands-on insights but often at higher time and expense. Explore how combining digital twinning with physical prototyping can revolutionize product development efficiency and accuracy.

Why it is important

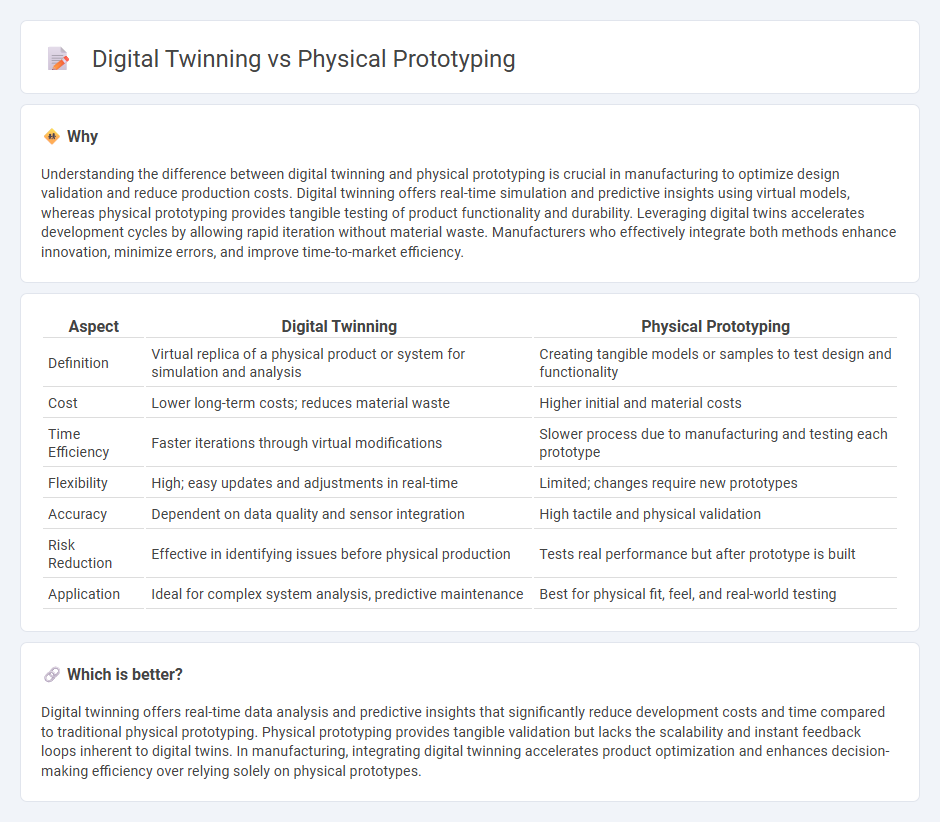

Understanding the difference between digital twinning and physical prototyping is crucial in manufacturing to optimize design validation and reduce production costs. Digital twinning offers real-time simulation and predictive insights using virtual models, whereas physical prototyping provides tangible testing of product functionality and durability. Leveraging digital twins accelerates development cycles by allowing rapid iteration without material waste. Manufacturers who effectively integrate both methods enhance innovation, minimize errors, and improve time-to-market efficiency.

Comparison Table

| Aspect | Digital Twinning | Physical Prototyping |

|---|---|---|

| Definition | Virtual replica of a physical product or system for simulation and analysis | Creating tangible models or samples to test design and functionality |

| Cost | Lower long-term costs; reduces material waste | Higher initial and material costs |

| Time Efficiency | Faster iterations through virtual modifications | Slower process due to manufacturing and testing each prototype |

| Flexibility | High; easy updates and adjustments in real-time | Limited; changes require new prototypes |

| Accuracy | Dependent on data quality and sensor integration | High tactile and physical validation |

| Risk Reduction | Effective in identifying issues before physical production | Tests real performance but after prototype is built |

| Application | Ideal for complex system analysis, predictive maintenance | Best for physical fit, feel, and real-world testing |

Which is better?

Digital twinning offers real-time data analysis and predictive insights that significantly reduce development costs and time compared to traditional physical prototyping. Physical prototyping provides tangible validation but lacks the scalability and instant feedback loops inherent to digital twins. In manufacturing, integrating digital twinning accelerates product optimization and enhances decision-making efficiency over relying solely on physical prototypes.

Connection

Digital twinning enhances physical prototyping by creating precise virtual replicas of manufacturing processes or products, enabling real-time simulation and analysis. This integration accelerates design validation, reduces material waste, and optimizes production efficiency through continuous feedback between digital models and physical prototypes. Leveraging IoT sensors and CAD data, manufacturers achieve more accurate iterations and predictive maintenance strategies.

Key Terms

CAD (Computer-Aided Design)

Physical prototyping involves creating tangible CAD-based models to evaluate design functionality and ergonomics in real-world conditions, while digital twinning uses advanced CAD data to develop precise virtual replicas for real-time simulation and performance analysis. CAD software like SolidWorks and AutoCAD empowers engineers to streamline iterations between physical models and digital twins, enhancing accuracy and reducing development costs. Explore the benefits of integrating physical prototyping with digital twinning to optimize your product design process.

Simulation

Physical prototyping involves creating tangible models to test design functionality, while digital twinning utilizes virtual replicas for real-time simulation and performance analysis. Simulation in digital twinning enables predictive maintenance, optimization, and scenario testing without physical constraints, enhancing efficiency and cost-effectiveness. Explore how integrating these approaches revolutionizes product development and operational strategies.

Additive Manufacturing

Additive Manufacturing benefits from digital twinning by enabling real-time simulation and optimization of 3D-printed parts, reducing material waste and accelerating design iterations compared to traditional physical prototyping. Digital twins create precise virtual replicas of AM processes, allowing for predictive maintenance and quality assurance that physical prototypes alone cannot offer. Explore how integrating digital twinning can revolutionize your additive manufacturing workflow for enhanced efficiency and product innovation.

Source and External Links

Turning Your Engineering Idea into Reality: A Guide to Physical Product Prototyping - Physical product prototyping is the process of creating a preliminary version of a physical product to test its design and functionality, allowing identification of issues and improvements before final production, and can be done using methods like 3D printing or using ready materials.

Guide to The Basic Concepts of a Physical Prototype - A physical prototype comes from abstract design to test and assess the design's practical aspects, ranging from simple devices to complex machines, helping clients understand real-life operation and often made using rapid prototyping techniques that save time and cost.

Digital vs Physical: Unveiling the Power of Rapid Prototyping - Physical prototypes provide critical tactile feedback, functional testing, material validation, and stakeholder engagement opportunities, making them essential for validating ergonomics, aesthetics, and mechanical function in product development.

dowidth.com

dowidth.com