Collaborative robots, or cobots, enhance manufacturing flexibility by working alongside human operators to perform precise tasks, increasing productivity and safety. Additive manufacturing cells utilize layer-by-layer construction to produce complex components with minimal waste, enabling rapid prototyping and customized production. Explore the distinct advantages of collaborative robots and additive manufacturing cells to determine the best fit for your manufacturing operations.

Why it is important

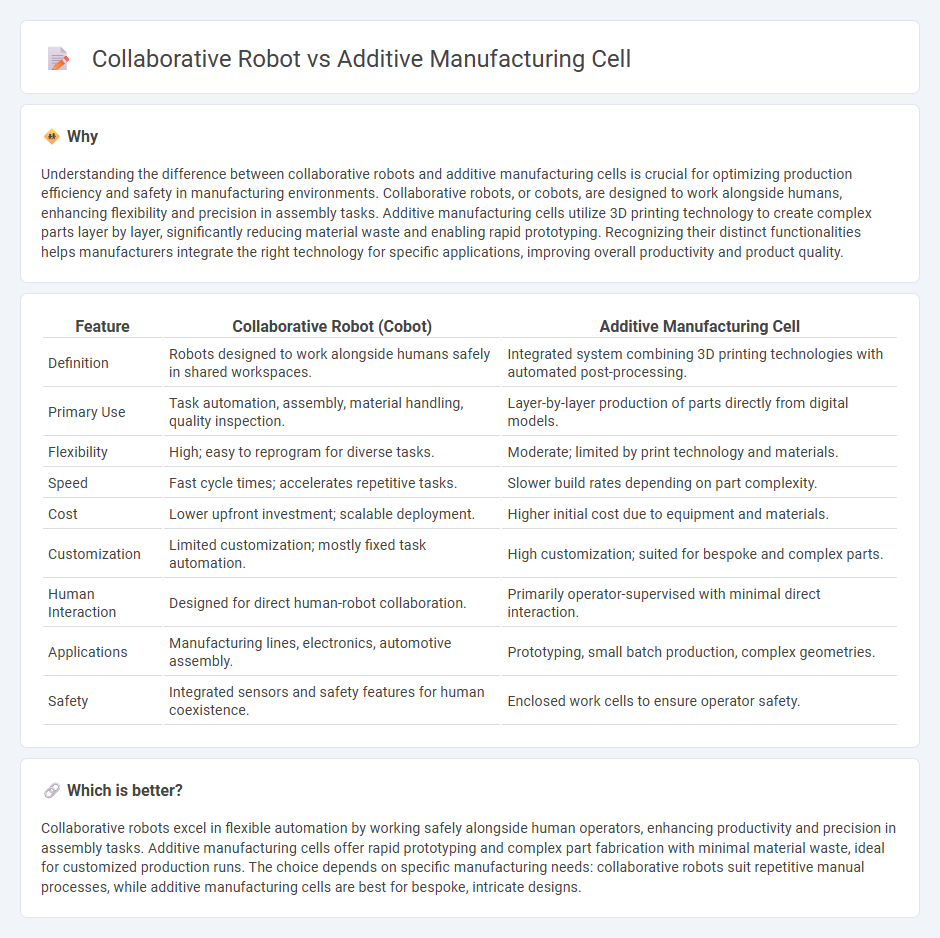

Understanding the difference between collaborative robots and additive manufacturing cells is crucial for optimizing production efficiency and safety in manufacturing environments. Collaborative robots, or cobots, are designed to work alongside humans, enhancing flexibility and precision in assembly tasks. Additive manufacturing cells utilize 3D printing technology to create complex parts layer by layer, significantly reducing material waste and enabling rapid prototyping. Recognizing their distinct functionalities helps manufacturers integrate the right technology for specific applications, improving overall productivity and product quality.

Comparison Table

| Feature | Collaborative Robot (Cobot) | Additive Manufacturing Cell |

|---|---|---|

| Definition | Robots designed to work alongside humans safely in shared workspaces. | Integrated system combining 3D printing technologies with automated post-processing. |

| Primary Use | Task automation, assembly, material handling, quality inspection. | Layer-by-layer production of parts directly from digital models. |

| Flexibility | High; easy to reprogram for diverse tasks. | Moderate; limited by print technology and materials. |

| Speed | Fast cycle times; accelerates repetitive tasks. | Slower build rates depending on part complexity. |

| Cost | Lower upfront investment; scalable deployment. | Higher initial cost due to equipment and materials. |

| Customization | Limited customization; mostly fixed task automation. | High customization; suited for bespoke and complex parts. |

| Human Interaction | Designed for direct human-robot collaboration. | Primarily operator-supervised with minimal direct interaction. |

| Applications | Manufacturing lines, electronics, automotive assembly. | Prototyping, small batch production, complex geometries. |

| Safety | Integrated sensors and safety features for human coexistence. | Enclosed work cells to ensure operator safety. |

Which is better?

Collaborative robots excel in flexible automation by working safely alongside human operators, enhancing productivity and precision in assembly tasks. Additive manufacturing cells offer rapid prototyping and complex part fabrication with minimal material waste, ideal for customized production runs. The choice depends on specific manufacturing needs: collaborative robots suit repetitive manual processes, while additive manufacturing cells are best for bespoke, intricate designs.

Connection

Collaborative robots enhance additive manufacturing cells by automating intricate tasks such as material handling and precision assembly, significantly improving production efficiency and accuracy. Integration of collaborative robots with 3D printers enables real-time quality control and faster prototyping cycles, reducing downtime and waste. This synergy accelerates product development timelines while maintaining high customization and scalability in manufacturing processes.

Key Terms

Layer-by-layer fabrication (Additive manufacturing cell)

Additive manufacturing cells utilize layer-by-layer fabrication to build complex geometries directly from digital models, enabling precise material deposition and minimizing waste. Collaborative robots, while versatile in automation tasks, generally do not specialize in the intricate, sequential layering process essential for additive manufacturing. Explore how additive manufacturing cells enhance production efficiency and product customization by learning more about their layer-by-layer fabrication capabilities.

Human-robot interaction (Collaborative robot)

Collaborative robots (cobots) enhance human-robot interaction by working safely alongside operators without extensive safety barriers, using sensors and machine learning to adapt to human behavior. Additive manufacturing cells, while efficient in automation, often require isolating human workers to ensure safety, limiting direct collaboration. Discover how collaborative robots redefine workplace synergy through advanced interaction technologies and safety features.

Automation integration

Additive manufacturing cells enhance automation by integrating precise, repeatable 3D printing processes within enclosed environments for optimized production quality and workflow consistency. Collaborative robots (cobots) offer flexible automation by working alongside human operators, facilitating seamless task sharing and adaptability in complex manufacturing settings. Explore how automation integration evolves with additive manufacturing cells and collaborative robots to improve efficiency and innovation.

Source and External Links

Fanuc/Fronius Wire Arc Additive Manufacturing Cell - This is a robotic metal additive manufacturing system used for large-scale metal prints with features like cold metal transfer and various sensors for data acquisition.

One Off Robotics and Meltio Introduce Turn-Key Metal Additive Manufacturing Cell - This collaboration offers a robotic metal AM cell powered by Meltio's wire-based laser Directed Energy Deposition (DED) process, allowing efficient production of metal parts.

Robotic Additive Manufacturing Cell at Formnext 2024 - This video showcases a robotic cell combining additive manufacturing and machining for producing complex parts like aerospace nozzles, integrating 3D printing, metrology, and spray application.

dowidth.com

dowidth.com