Digital twin technology creates virtual replicas of physical assets to monitor and simulate real-time performance, enhancing manufacturing efficiency and reducing downtime. Predictive maintenance leverages data analytics and machine learning to forecast equipment failures before they occur, minimizing unplanned outages and maintenance costs. Explore how integrating digital twins with predictive maintenance can revolutionize manufacturing workflows and asset management.

Why it is important

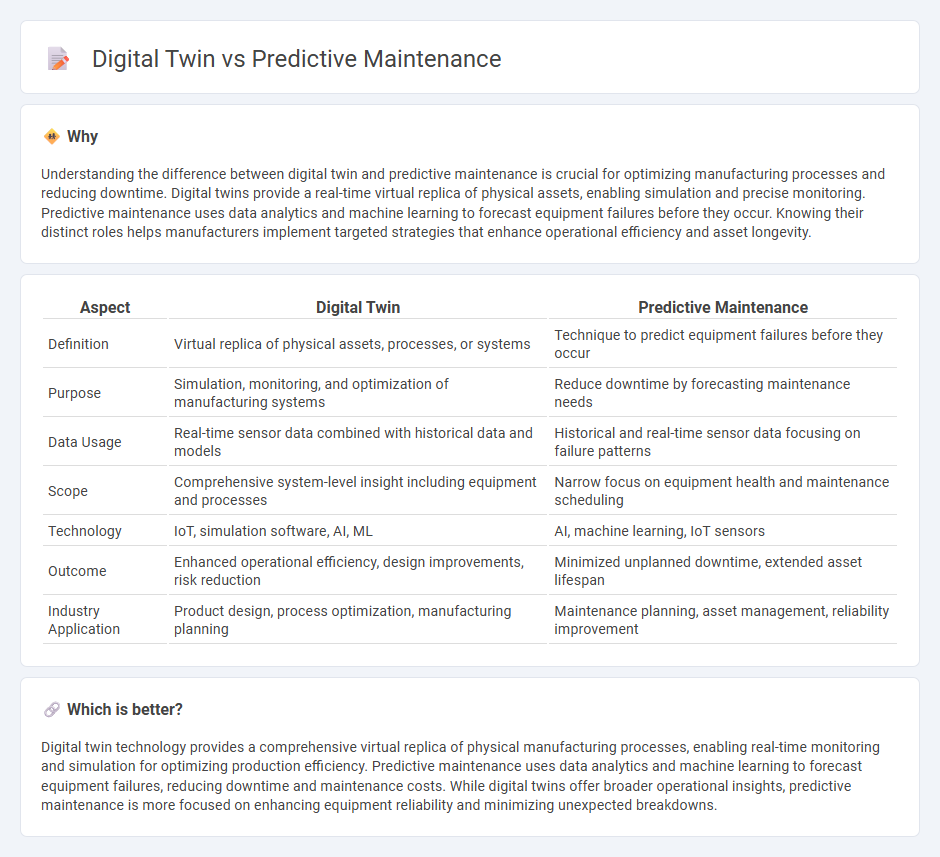

Understanding the difference between digital twin and predictive maintenance is crucial for optimizing manufacturing processes and reducing downtime. Digital twins provide a real-time virtual replica of physical assets, enabling simulation and precise monitoring. Predictive maintenance uses data analytics and machine learning to forecast equipment failures before they occur. Knowing their distinct roles helps manufacturers implement targeted strategies that enhance operational efficiency and asset longevity.

Comparison Table

| Aspect | Digital Twin | Predictive Maintenance |

|---|---|---|

| Definition | Virtual replica of physical assets, processes, or systems | Technique to predict equipment failures before they occur |

| Purpose | Simulation, monitoring, and optimization of manufacturing systems | Reduce downtime by forecasting maintenance needs |

| Data Usage | Real-time sensor data combined with historical data and models | Historical and real-time sensor data focusing on failure patterns |

| Scope | Comprehensive system-level insight including equipment and processes | Narrow focus on equipment health and maintenance scheduling |

| Technology | IoT, simulation software, AI, ML | AI, machine learning, IoT sensors |

| Outcome | Enhanced operational efficiency, design improvements, risk reduction | Minimized unplanned downtime, extended asset lifespan |

| Industry Application | Product design, process optimization, manufacturing planning | Maintenance planning, asset management, reliability improvement |

Which is better?

Digital twin technology provides a comprehensive virtual replica of physical manufacturing processes, enabling real-time monitoring and simulation for optimizing production efficiency. Predictive maintenance uses data analytics and machine learning to forecast equipment failures, reducing downtime and maintenance costs. While digital twins offer broader operational insights, predictive maintenance is more focused on enhancing equipment reliability and minimizing unexpected breakdowns.

Connection

Digital twin technology creates a virtual replica of manufacturing equipment, enabling real-time monitoring and analysis of machine performance. Predictive maintenance leverages these digital replicas to forecast potential failures and schedule timely interventions, reducing unplanned downtime. Integrating digital twins with predictive analytics enhances operational efficiency and extends asset lifespan in manufacturing processes.

Key Terms

**Predictive Maintenance:**

Predictive maintenance leverages real-time sensor data and machine learning algorithms to anticipate equipment failures before they occur, significantly reducing downtime and maintenance costs. It continuously monitors asset conditions, analyzing patterns to schedule timely interventions and optimize operational efficiency. Explore how predictive maintenance transforms asset management and enhances reliability in industrial settings.

Condition Monitoring

Predictive maintenance leverages real-time condition monitoring data to forecast equipment failures and schedule timely interventions, reducing downtime and maintenance costs. Digital twins create precise virtual replicas of physical assets, enhancing condition monitoring by simulating performance, detecting anomalies, and optimizing operations in a dynamic digital environment. Explore how integrating these technologies can revolutionize your maintenance strategy and boost operational efficiency.

Failure Prediction

Predictive maintenance leverages sensor data and machine learning algorithms to analyze equipment conditions and predict potential failures before they occur, minimizing downtime and repair costs. Digital twins create a virtual replica of physical assets, simulating real-time performance and failure scenarios using advanced modeling techniques to provide deeper insights into operational health. Explore how integrating predictive maintenance with digital twin technology enhances failure prediction accuracy and optimizes asset management strategies.

Source and External Links

What is Predictive Maintenance? - Predictive maintenance uses sensor data and machine learning to predict equipment failures ahead of time, allowing maintenance only when needed and preventing unnecessary costs and downtime by constantly monitoring actual equipment condition in real-time.

Predictive maintenance - This approach estimates when maintenance should be performed based on the actual condition of equipment, reducing unplanned stops by enabling planned maintenance, thereby increasing equipment lifetime and plant availability through condition-based monitoring and forecasting.

What is Predictive Maintenance? Benefits, Challenges & Solutions - Predictive maintenance analyzes real-time data from sensors and fleet operations, helping to accurately forecast failures before they happen, prioritize urgent repairs, optimize inventory, extend asset lifespan, and improve safety and fuel economy for fleet management.

dowidth.com

dowidth.com