Remanufacturing restores used products to like-new condition by disassembling, cleaning, and replacing parts, significantly reducing waste and resource consumption compared to traditional manufacturing. Green manufacturing emphasizes sustainable processes, incorporating renewable energy, eco-friendly materials, and waste minimization to reduce the overall environmental impact. Explore the distinctions and benefits of remanufacturing versus green manufacturing to enhance sustainable production strategies.

Why it is important

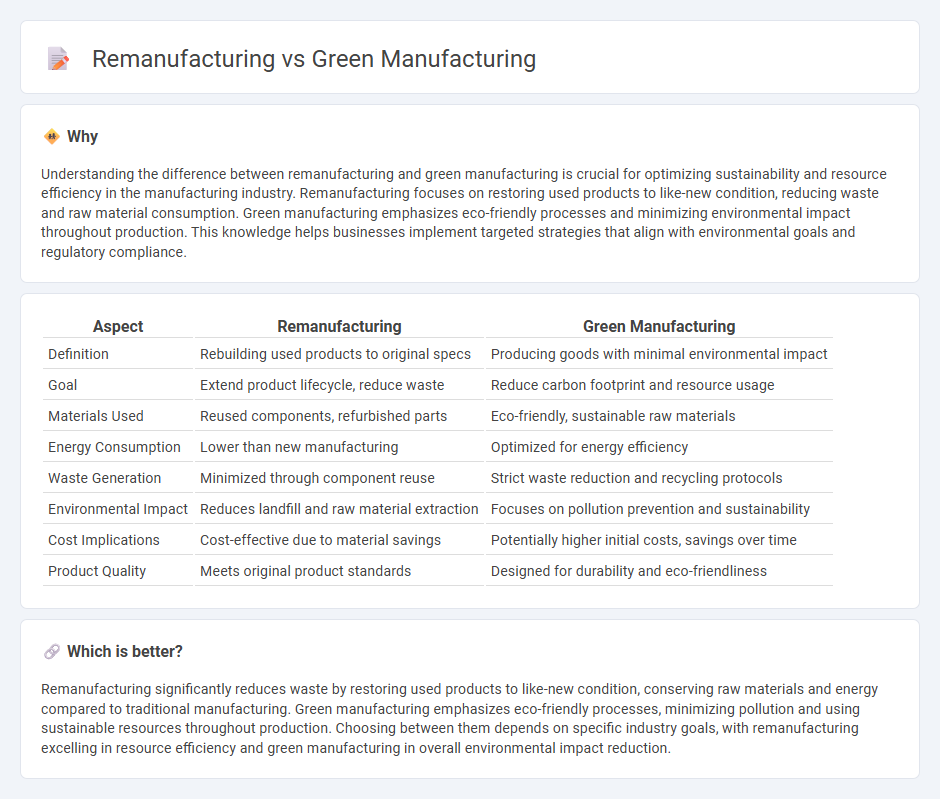

Understanding the difference between remanufacturing and green manufacturing is crucial for optimizing sustainability and resource efficiency in the manufacturing industry. Remanufacturing focuses on restoring used products to like-new condition, reducing waste and raw material consumption. Green manufacturing emphasizes eco-friendly processes and minimizing environmental impact throughout production. This knowledge helps businesses implement targeted strategies that align with environmental goals and regulatory compliance.

Comparison Table

| Aspect | Remanufacturing | Green Manufacturing |

|---|---|---|

| Definition | Rebuilding used products to original specs | Producing goods with minimal environmental impact |

| Goal | Extend product lifecycle, reduce waste | Reduce carbon footprint and resource usage |

| Materials Used | Reused components, refurbished parts | Eco-friendly, sustainable raw materials |

| Energy Consumption | Lower than new manufacturing | Optimized for energy efficiency |

| Waste Generation | Minimized through component reuse | Strict waste reduction and recycling protocols |

| Environmental Impact | Reduces landfill and raw material extraction | Focuses on pollution prevention and sustainability |

| Cost Implications | Cost-effective due to material savings | Potentially higher initial costs, savings over time |

| Product Quality | Meets original product standards | Designed for durability and eco-friendliness |

Which is better?

Remanufacturing significantly reduces waste by restoring used products to like-new condition, conserving raw materials and energy compared to traditional manufacturing. Green manufacturing emphasizes eco-friendly processes, minimizing pollution and using sustainable resources throughout production. Choosing between them depends on specific industry goals, with remanufacturing excelling in resource efficiency and green manufacturing in overall environmental impact reduction.

Connection

Remanufacturing reduces waste by restoring used products to like-new condition, conserving raw materials and energy in manufacturing processes. Green manufacturing integrates eco-friendly practices, such as minimizing emissions and using sustainable resources, which complement remanufacturing's goal of resource efficiency. Both approaches contribute to a circular economy by extending product life cycles and lowering environmental impact.

Key Terms

Sustainability

Green manufacturing minimizes environmental impact by using eco-friendly materials, reducing waste, and optimizing energy efficiency in production processes. Remanufacturing extends product life cycles by restoring used products to like-new condition, significantly cutting resource consumption, and decreasing landfill contributions. Explore the benefits and innovations in sustainability for both green manufacturing and remanufacturing to enhance your eco-conscious strategies.

Circular Economy

Green manufacturing reduces environmental impact by using sustainable materials and energy-efficient processes, minimizing waste from the outset. Remanufacturing extends product life by restoring used items to like-new condition, enhancing resource efficiency and reducing landfill contributions. Explore how these approaches drive the Circular Economy's goal of sustainable resource management.

Resource Efficiency

Green manufacturing minimizes resource consumption by integrating energy-efficient processes, sustainable materials, and waste reduction methods to lower environmental impact. Remanufacturing enhances resource efficiency by refurbishing used products to original specifications, significantly reducing raw material use and energy compared to new production. Discover how both approaches contribute to circular economy strategies and sustainable industrial practices.

Source and External Links

What Is Green Manufacturing? - Green manufacturing refers to producing goods in ways that reduce carbon footprints by conserving energy and natural resources, using renewable energy and efficient technologies to minimize environmental impact while benefiting businesses through cost savings and improved reputation.

What is Green Manufacturing? (Plus 5 Steps to a Greener ...) - Green manufacturing, or sustainable manufacturing, focuses on minimizing environmental impacts and maximizing resource efficiency, with practical steps like adopting lean manufacturing principles to reduce waste and improve sustainability in production processes.

Green Manufacturing: The Business Benefits of Sustainability - Green manufacturing commits to using fewer pollutants and natural resources, producing less waste and emissions, which helps companies reduce costs, increase productivity, and improve environmental impact while benefiting business performance.

dowidth.com

dowidth.com