Hyperautomation integrates advanced technologies like AI and robotic process automation to enhance manufacturing efficiency by automating complex workflows. Digital twin technology creates real-time, virtual replicas of physical assets, enabling predictive maintenance and optimized production processes. Explore the key differences and benefits of hyperautomation and digital twins in modern manufacturing to elevate your operational strategy.

Why it is important

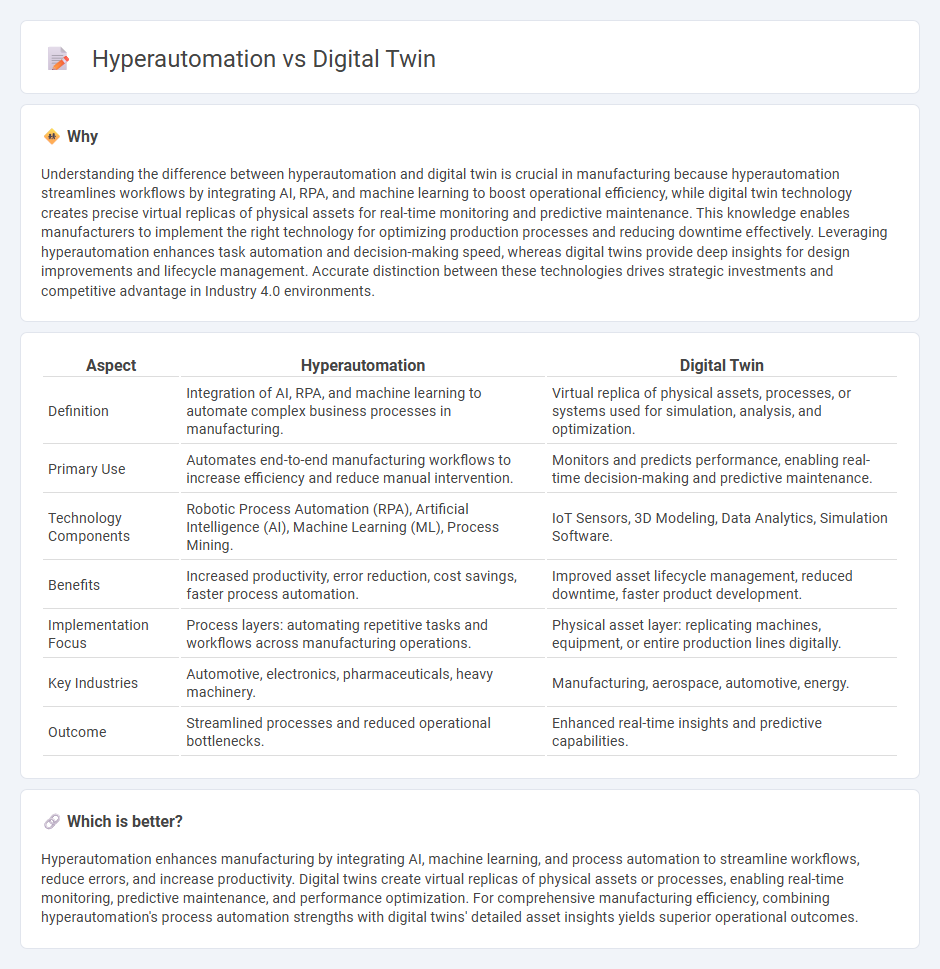

Understanding the difference between hyperautomation and digital twin is crucial in manufacturing because hyperautomation streamlines workflows by integrating AI, RPA, and machine learning to boost operational efficiency, while digital twin technology creates precise virtual replicas of physical assets for real-time monitoring and predictive maintenance. This knowledge enables manufacturers to implement the right technology for optimizing production processes and reducing downtime effectively. Leveraging hyperautomation enhances task automation and decision-making speed, whereas digital twins provide deep insights for design improvements and lifecycle management. Accurate distinction between these technologies drives strategic investments and competitive advantage in Industry 4.0 environments.

Comparison Table

| Aspect | Hyperautomation | Digital Twin |

|---|---|---|

| Definition | Integration of AI, RPA, and machine learning to automate complex business processes in manufacturing. | Virtual replica of physical assets, processes, or systems used for simulation, analysis, and optimization. |

| Primary Use | Automates end-to-end manufacturing workflows to increase efficiency and reduce manual intervention. | Monitors and predicts performance, enabling real-time decision-making and predictive maintenance. |

| Technology Components | Robotic Process Automation (RPA), Artificial Intelligence (AI), Machine Learning (ML), Process Mining. | IoT Sensors, 3D Modeling, Data Analytics, Simulation Software. |

| Benefits | Increased productivity, error reduction, cost savings, faster process automation. | Improved asset lifecycle management, reduced downtime, faster product development. |

| Implementation Focus | Process layers: automating repetitive tasks and workflows across manufacturing operations. | Physical asset layer: replicating machines, equipment, or entire production lines digitally. |

| Key Industries | Automotive, electronics, pharmaceuticals, heavy machinery. | Manufacturing, aerospace, automotive, energy. |

| Outcome | Streamlined processes and reduced operational bottlenecks. | Enhanced real-time insights and predictive capabilities. |

Which is better?

Hyperautomation enhances manufacturing by integrating AI, machine learning, and process automation to streamline workflows, reduce errors, and increase productivity. Digital twins create virtual replicas of physical assets or processes, enabling real-time monitoring, predictive maintenance, and performance optimization. For comprehensive manufacturing efficiency, combining hyperautomation's process automation strengths with digital twins' detailed asset insights yields superior operational outcomes.

Connection

Hyperautomation leverages digital twins to create virtual replicas of manufacturing processes, enabling real-time monitoring and predictive analytics that optimize production efficiency. Digital twins provide detailed insights into equipment performance and process flows, allowing hyperautomation systems to identify bottlenecks and automate corrective actions swiftly. Integrating these technologies accelerates decision-making, reduces downtime, and enhances product quality in smart factories.

Key Terms

Real-time Simulation

Digital twin technology enables real-time simulation by creating dynamic virtual models that reflect physical assets and processes, allowing continuous monitoring and predictive analytics. Hyperautomation integrates AI, machine learning, and robotic process automation to streamline workflows and decision-making but typically relies on predefined rules rather than continuous simulation. Explore how combining digital twins with hyperautomation can unlock advanced operational efficiencies and innovation.

Process Orchestration

Digital twin technology provides a dynamic virtual representation of physical processes, enabling real-time monitoring and predictive analysis to optimize process orchestration. Hyperautomation integrates advanced technologies like AI, machine learning, and robotic process automation to automate complex workflows and enhance decision-making in process orchestration. Explore deeper insights into how these innovations transform operational efficiency and orchestration strategies.

Predictive Analytics

Digital twin technology creates virtual replicas of physical assets to monitor real-time performance and predict future failures through advanced sensor data analysis. Hyperautomation leverages AI-driven tools and robotic process automation (RPA) to streamline complex workflows, enhancing predictive analytics for operational efficiency and decision-making. Explore how integrating digital twins with hyperautomation advances predictive analytics in industry applications.

Source and External Links

What Is a Digital Twin? | IBM - A digital twin is a virtual representation of a physical object or system updated with real-time data, using simulation and machine learning to analyze performance and improve the original entity.

Definition of a Digital Twin - It is a synchronized, data-driven virtual representation of real-world entities and processes that supports continuous improvement, decision-making, and future simulation.

Digital twin - Wikipedia - A digital twin is a digital model of a physical product, system, or process that is updated with real-time data to simulate, monitor, and optimize operations throughout its lifecycle.

dowidth.com

dowidth.com