Flexible manufacturing systems enhance production efficiency by adapting quickly to changes in product design and volume, utilizing automated machinery and modular equipment. Just-in-time manufacturing focuses on minimizing inventory and reducing waste by producing goods precisely in response to customer demand, optimizing supply chain coordination. Discover how these manufacturing strategies transform operational performance and competitiveness.

Why it is important

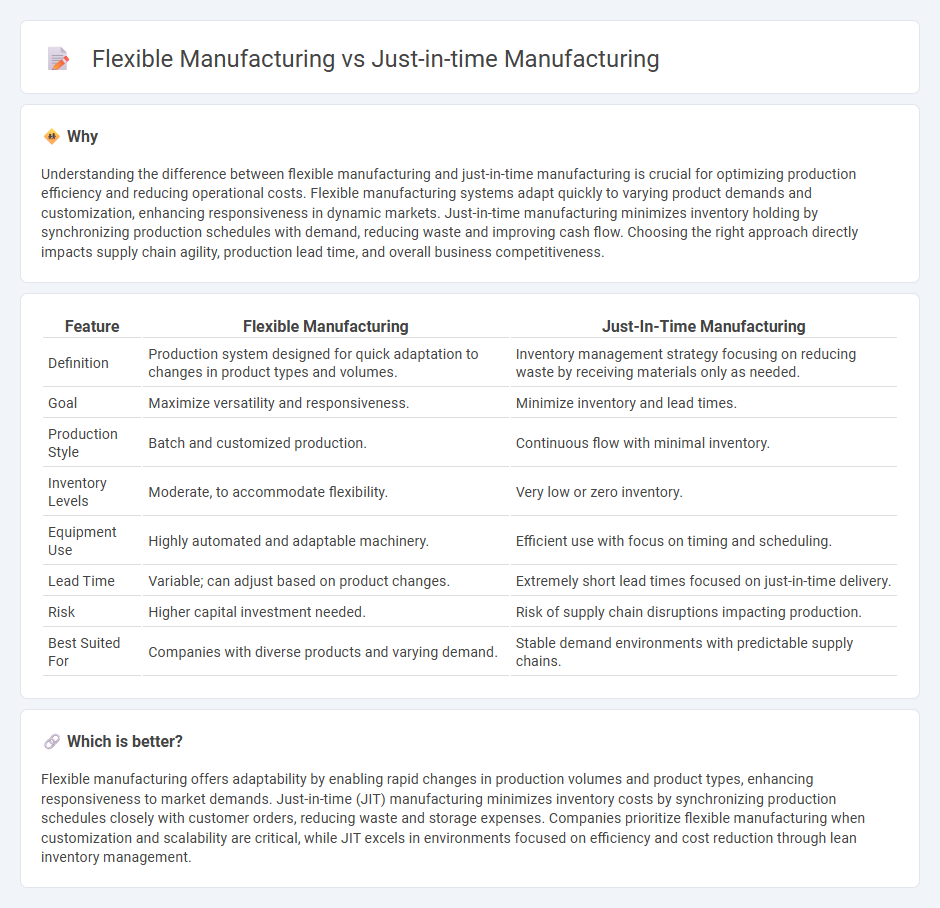

Understanding the difference between flexible manufacturing and just-in-time manufacturing is crucial for optimizing production efficiency and reducing operational costs. Flexible manufacturing systems adapt quickly to varying product demands and customization, enhancing responsiveness in dynamic markets. Just-in-time manufacturing minimizes inventory holding by synchronizing production schedules with demand, reducing waste and improving cash flow. Choosing the right approach directly impacts supply chain agility, production lead time, and overall business competitiveness.

Comparison Table

| Feature | Flexible Manufacturing | Just-In-Time Manufacturing |

|---|---|---|

| Definition | Production system designed for quick adaptation to changes in product types and volumes. | Inventory management strategy focusing on reducing waste by receiving materials only as needed. |

| Goal | Maximize versatility and responsiveness. | Minimize inventory and lead times. |

| Production Style | Batch and customized production. | Continuous flow with minimal inventory. |

| Inventory Levels | Moderate, to accommodate flexibility. | Very low or zero inventory. |

| Equipment Use | Highly automated and adaptable machinery. | Efficient use with focus on timing and scheduling. |

| Lead Time | Variable; can adjust based on product changes. | Extremely short lead times focused on just-in-time delivery. |

| Risk | Higher capital investment needed. | Risk of supply chain disruptions impacting production. |

| Best Suited For | Companies with diverse products and varying demand. | Stable demand environments with predictable supply chains. |

Which is better?

Flexible manufacturing offers adaptability by enabling rapid changes in production volumes and product types, enhancing responsiveness to market demands. Just-in-time (JIT) manufacturing minimizes inventory costs by synchronizing production schedules closely with customer orders, reducing waste and storage expenses. Companies prioritize flexible manufacturing when customization and scalability are critical, while JIT excels in environments focused on efficiency and cost reduction through lean inventory management.

Connection

Flexible manufacturing systems enable quick adaptation to product changes and variable demand, which supports the principles of just-in-time (JIT) manufacturing by reducing inventory levels and minimizing waste. Just-in-time manufacturing relies on the flexibility to produce components precisely when needed, ensuring efficient workflow and timely delivery. Together, these approaches enhance production efficiency, lower costs, and improve responsiveness in manufacturing operations.

Key Terms

Inventory Management

Just-in-time (JIT) manufacturing minimizes inventory levels by synchronizing production schedules closely with demand, reducing storage costs and waste while increasing efficiency. Flexible manufacturing systems (FMS) maintain moderate inventory to accommodate variability in product types and volumes, enabling rapid adaptation to market changes without excessive stock buildup. Explore deeper insights into how inventory management strategies differ between JIT and flexible manufacturing to optimize supply chain performance.

Production Scheduling

Just-in-time manufacturing minimizes inventory by scheduling production precisely when needed, reducing waste and improving efficiency. Flexible manufacturing emphasizes adaptability in production schedules to accommodate fluctuations in demand and product variety, ensuring responsiveness. Explore the advantages of each approach to optimize your production scheduling strategies.

Adaptability

Just-in-time manufacturing minimizes inventory by producing goods only as needed, resulting in limited adaptability to sudden demand changes or supply disruptions. Flexible manufacturing systems enhance adaptability by enabling quick reconfiguration of production processes to accommodate varying product types and volumes. Explore further to understand how adaptability impacts production efficiency and cost management in these manufacturing approaches.

Source and External Links

Just In Time Manufacturing: Definition, Benefits, and Origin - This article provides an in-depth look at Just-in-Time manufacturing, its benefits, and how it helps reduce operational costs by minimizing inventory and improving efficiency.

Lean manufacturing - This Wikipedia page discusses lean manufacturing, which includes Just-in-Time methods, focusing on efficiency, productivity, and eliminating waste to meet customer demand.

What is just-in-time manufacturing (JIT manufacturing) - This TechTarget article explains JIT manufacturing as a model that creates items based on demand to increase efficiency and reduce production costs by eliminating waste.

dowidth.com

dowidth.com