Additive manufacturing builds complex metal and plastic parts layer by layer, enabling high customization and reduced material waste compared to die casting's traditional mold-based process. Die casting excels in high-volume production with consistent quality and faster cycle times, using molten metal injected into steel molds. Explore further to understand which manufacturing method best suits your production goals and product requirements.

Why it is important

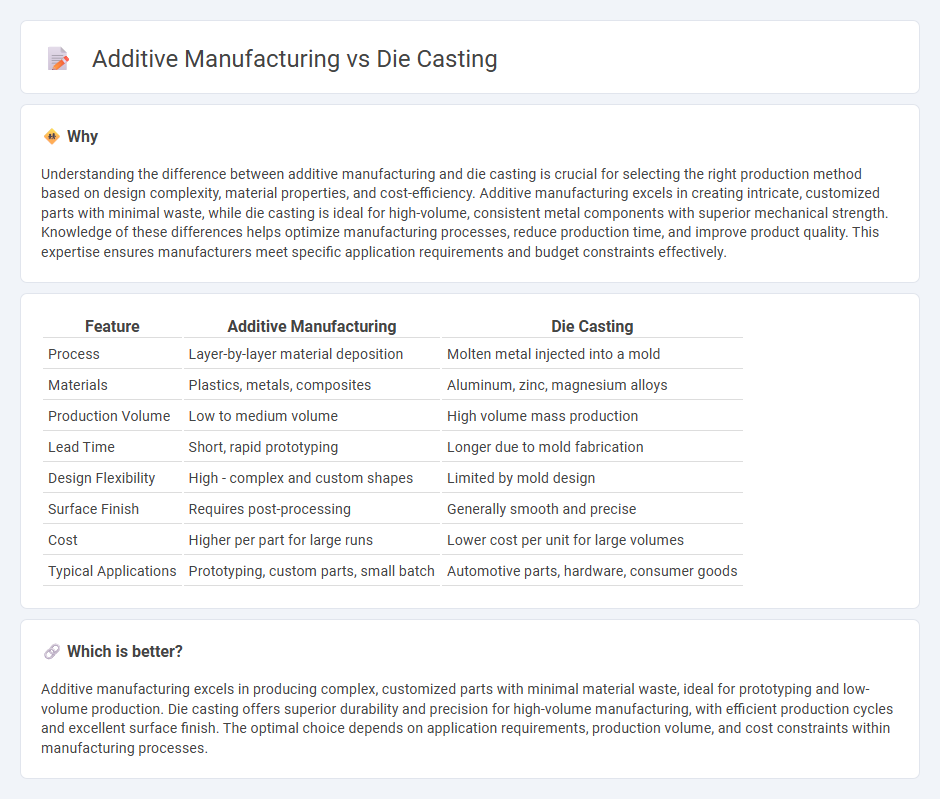

Understanding the difference between additive manufacturing and die casting is crucial for selecting the right production method based on design complexity, material properties, and cost-efficiency. Additive manufacturing excels in creating intricate, customized parts with minimal waste, while die casting is ideal for high-volume, consistent metal components with superior mechanical strength. Knowledge of these differences helps optimize manufacturing processes, reduce production time, and improve product quality. This expertise ensures manufacturers meet specific application requirements and budget constraints effectively.

Comparison Table

| Feature | Additive Manufacturing | Die Casting |

|---|---|---|

| Process | Layer-by-layer material deposition | Molten metal injected into a mold |

| Materials | Plastics, metals, composites | Aluminum, zinc, magnesium alloys |

| Production Volume | Low to medium volume | High volume mass production |

| Lead Time | Short, rapid prototyping | Longer due to mold fabrication |

| Design Flexibility | High - complex and custom shapes | Limited by mold design |

| Surface Finish | Requires post-processing | Generally smooth and precise |

| Cost | Higher per part for large runs | Lower cost per unit for large volumes |

| Typical Applications | Prototyping, custom parts, small batch | Automotive parts, hardware, consumer goods |

Which is better?

Additive manufacturing excels in producing complex, customized parts with minimal material waste, ideal for prototyping and low-volume production. Die casting offers superior durability and precision for high-volume manufacturing, with efficient production cycles and excellent surface finish. The optimal choice depends on application requirements, production volume, and cost constraints within manufacturing processes.

Connection

Additive manufacturing and die casting intersect in the prototyping and tooling phases of production, where 3D-printed patterns and molds accelerate design iterations. Additive techniques enable rapid creation of complex geometries that serve as master models for die casting dies, reducing lead time and tooling costs. The integration of both processes enhances manufacturing efficiency by combining quick customization from additive methods with high-volume, precise metal component production through die casting.

Key Terms

Mold (Die)

Die casting molds are typically made from hardened steel, allowing for high durability and precise reproduction of complex shapes in large-scale production. Additive manufacturing molds, created layer-by-layer using materials like photopolymers or metals, offer rapid prototyping flexibility and customization at lower production volumes. Explore detailed comparisons on mold material properties, cost efficiency, and production speed to understand which process suits your manufacturing needs best.

Layer-by-Layer

Die casting involves injecting molten metal into a mold to form precise shapes efficiently, whereas additive manufacturing builds parts layer-by-layer using materials like metal powders or polymers, allowing for complex geometries and customization. The layer-by-layer process in additive manufacturing enables intricate internal features and reduced material waste, contrasting with the one-step solidification of die casting. Explore more about the advantages and applications of both methods for optimized production.

Material Feedstock

Die casting primarily uses molten metal alloys such as aluminum, zinc, and magnesium as feedstock, offering high strength and excellent surface finish for mass production. Additive manufacturing utilizes diverse material feedstocks including metal powders, thermoplastics, and composites, enabling complex geometries and rapid prototyping with less material waste. Explore further to understand how feedstock choices impact manufacturing efficiency and product performance.

Source and External Links

Die casting - Wikipedia - Die casting is a metal casting process characterized by forcing molten metal under high pressure into a mold cavity made of hardened steel dies, mostly used for non-ferrous metals like zinc, aluminum, and magnesium, suited for high-volume production of small to medium-sized parts with good surface finish and dimensional accuracy.

Die Casting General Overview: Process, Materials & Applications - Die casting produces metal parts by injecting molten metal into a steel or aluminum mold under high pressure, enabling fast, cost-effective manufacturing with tight tolerances and smooth finishes, widely used in automotive, aerospace, and electronics industries.

Die Casting - What Is It, Process, Types and Benefits - Fractory - The die casting process involves six steps including mold creation via CNC machining, metal injection under high pressure, cooling, casting removal, and finishing, with a focus on high precision and elimination of defects through advanced CAD/CAM design and quality molds.

dowidth.com

dowidth.com