Machine vision inspection uses cameras and software algorithms to detect surface defects, assembly errors, and dimensional variations in manufacturing processes, ensuring high precision and speed. Thermal imaging captures infrared radiation to identify temperature anomalies, such as overheating components or insulation failures, enhancing predictive maintenance and quality control. Explore the differences and applications of these technologies to optimize your manufacturing quality assurance strategies.

Why it is important

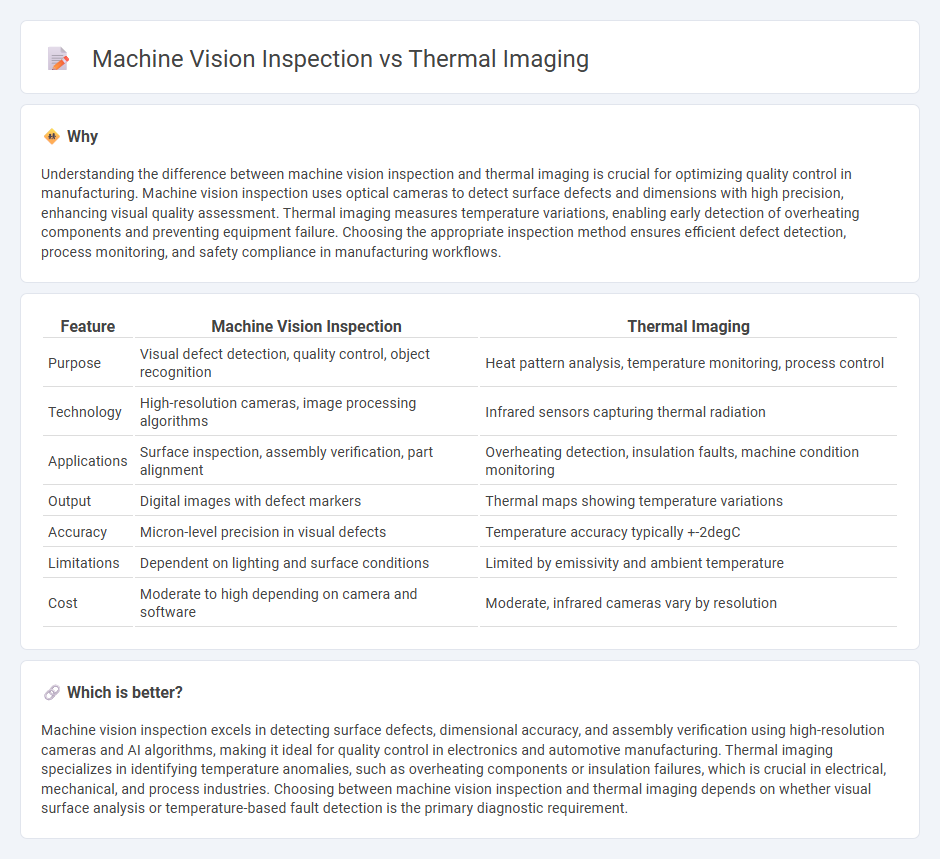

Understanding the difference between machine vision inspection and thermal imaging is crucial for optimizing quality control in manufacturing. Machine vision inspection uses optical cameras to detect surface defects and dimensions with high precision, enhancing visual quality assessment. Thermal imaging measures temperature variations, enabling early detection of overheating components and preventing equipment failure. Choosing the appropriate inspection method ensures efficient defect detection, process monitoring, and safety compliance in manufacturing workflows.

Comparison Table

| Feature | Machine Vision Inspection | Thermal Imaging |

|---|---|---|

| Purpose | Visual defect detection, quality control, object recognition | Heat pattern analysis, temperature monitoring, process control |

| Technology | High-resolution cameras, image processing algorithms | Infrared sensors capturing thermal radiation |

| Applications | Surface inspection, assembly verification, part alignment | Overheating detection, insulation faults, machine condition monitoring |

| Output | Digital images with defect markers | Thermal maps showing temperature variations |

| Accuracy | Micron-level precision in visual defects | Temperature accuracy typically +-2degC |

| Limitations | Dependent on lighting and surface conditions | Limited by emissivity and ambient temperature |

| Cost | Moderate to high depending on camera and software | Moderate, infrared cameras vary by resolution |

Which is better?

Machine vision inspection excels in detecting surface defects, dimensional accuracy, and assembly verification using high-resolution cameras and AI algorithms, making it ideal for quality control in electronics and automotive manufacturing. Thermal imaging specializes in identifying temperature anomalies, such as overheating components or insulation failures, which is crucial in electrical, mechanical, and process industries. Choosing between machine vision inspection and thermal imaging depends on whether visual surface analysis or temperature-based fault detection is the primary diagnostic requirement.

Connection

Machine vision inspection utilizes advanced cameras and image processing algorithms to detect surface defects and ensure product quality in manufacturing. Thermal imaging complements this by capturing heat patterns and temperature variations, revealing hidden flaws such as overheating components or insulation failures. Combining these technologies enhances defect detection accuracy, reduces downtime, and improves overall manufacturing process efficiency.

Key Terms

Infrared Sensors

Thermal imaging leverages infrared sensors to detect temperature variations by capturing emitted heat, providing crucial data for applications like electrical inspections and predictive maintenance. Machine vision inspection, while primarily using visible light cameras, can integrate infrared sensors for enhanced defect detection and quality control in manufacturing processes. Explore how infrared sensor technology can optimize both thermal imaging and machine vision inspection for your specific industrial needs.

Image Processing Algorithms

Thermal imaging leverages infrared sensors to detect temperature variations, enabling identification of heat patterns and anomalies invisible to the naked eye, processed through algorithms emphasizing thermal contrast and emissivity adjustments. Machine vision inspection utilizes digital cameras and illumination techniques to capture detailed visual data, relying on advanced image processing algorithms such as edge detection, pattern recognition, and deep learning-based defect classification. Discover how these distinct image processing algorithms enhance inspection accuracy by exploring their applications and capabilities.

Defect Detection

Thermal imaging excels at defect detection by capturing temperature variations that reveal hidden faults such as cracks, delaminations, or electrical issues in materials. Machine vision inspection relies on high-resolution cameras and advanced algorithms to identify surface defects like scratches, misalignments, or contamination in real-time production environments. Explore the strengths and applications of both technologies to optimize your defect detection strategies.

Source and External Links

How Infrared Cameras Work - Fluke - Thermal imaging is a non-invasive technique that uses infrared technology to detect and visualize heat emissions from objects, converting invisible infrared energy into a visible color-coded image that highlights temperature variations for industrial and safety applications.

Thermography - Wikipedia - Thermography, or thermal imaging, captures infrared radiation emitted by all objects above absolute zero using specialized cameras, producing images called thermograms that reveal temperature differences and are widely used in surveillance, medicine, and industrial diagnostics.

Thermographic Inspections - U.S. Department of Energy - Thermal imaging cameras create detailed 2D pictures (thermograms) of surface heat variations, enabling detection of energy loss, insulation defects, and mechanical or electrical issues in buildings and industrial systems.

dowidth.com

dowidth.com