Collaborative robots enhance manufacturing efficiency by working alongside human operators to perform repetitive or precision tasks with high accuracy, reducing errors and increasing throughput. Inspection stations use advanced sensors and imaging technology to ensure product quality by automatically identifying defects and deviations in real-time. Explore the detailed differences and benefits of collaborative robots versus inspection stations to optimize your manufacturing process.

Why it is important

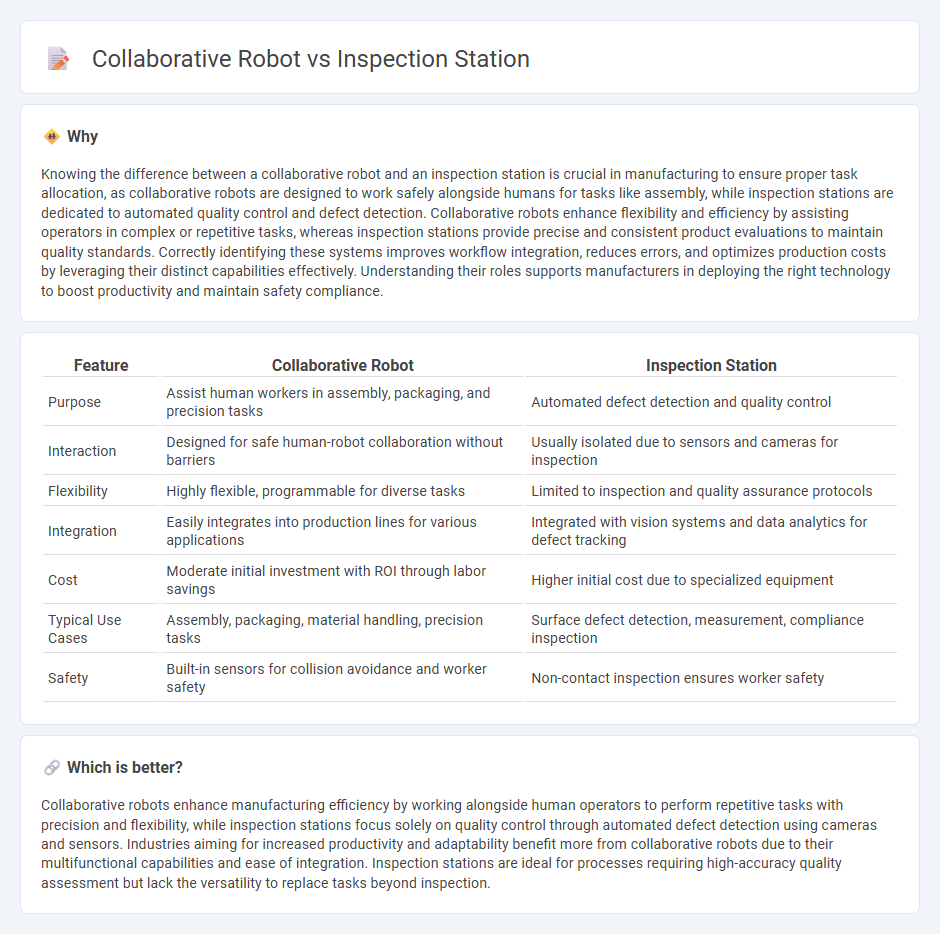

Knowing the difference between a collaborative robot and an inspection station is crucial in manufacturing to ensure proper task allocation, as collaborative robots are designed to work safely alongside humans for tasks like assembly, while inspection stations are dedicated to automated quality control and defect detection. Collaborative robots enhance flexibility and efficiency by assisting operators in complex or repetitive tasks, whereas inspection stations provide precise and consistent product evaluations to maintain quality standards. Correctly identifying these systems improves workflow integration, reduces errors, and optimizes production costs by leveraging their distinct capabilities effectively. Understanding their roles supports manufacturers in deploying the right technology to boost productivity and maintain safety compliance.

Comparison Table

| Feature | Collaborative Robot | Inspection Station |

|---|---|---|

| Purpose | Assist human workers in assembly, packaging, and precision tasks | Automated defect detection and quality control |

| Interaction | Designed for safe human-robot collaboration without barriers | Usually isolated due to sensors and cameras for inspection |

| Flexibility | Highly flexible, programmable for diverse tasks | Limited to inspection and quality assurance protocols |

| Integration | Easily integrates into production lines for various applications | Integrated with vision systems and data analytics for defect tracking |

| Cost | Moderate initial investment with ROI through labor savings | Higher initial cost due to specialized equipment |

| Typical Use Cases | Assembly, packaging, material handling, precision tasks | Surface defect detection, measurement, compliance inspection |

| Safety | Built-in sensors for collision avoidance and worker safety | Non-contact inspection ensures worker safety |

Which is better?

Collaborative robots enhance manufacturing efficiency by working alongside human operators to perform repetitive tasks with precision and flexibility, while inspection stations focus solely on quality control through automated defect detection using cameras and sensors. Industries aiming for increased productivity and adaptability benefit more from collaborative robots due to their multifunctional capabilities and ease of integration. Inspection stations are ideal for processes requiring high-accuracy quality assessment but lack the versatility to replace tasks beyond inspection.

Connection

Collaborative robots (cobots) enhance manufacturing efficiency by integrating seamlessly with inspection stations to perform precise quality control tasks. Cobots equipped with advanced sensors and vision systems enable real-time defect detection and measurement, reducing human error and inspection cycle times. This synergy accelerates production processes and ensures consistent product standards in smart manufacturing environments.

Key Terms

Quality Control

Inspection stations utilize fixed sensors and cameras to perform precise quality control by detecting surface defects, dimensions, and assembly accuracy in manufacturing lines. Collaborative robots (cobots) enhance quality control by combining automated inspection with adaptive handling, enabling real-time adjustments and seamless integration in production environments. Explore how these technologies transform quality control processes and improve manufacturing efficiency.

Human-Robot Interaction

Inspection stations integrate fixed sensors and cameras to monitor product quality, while collaborative robots (cobots) facilitate dynamic Human-Robot Interaction (HRI) by working safely alongside operators. Cobots enhance productivity by adapting to human movements and providing intuitive control interfaces, optimizing ergonomic workflow and reducing operator fatigue. Explore the latest advancements in HRI technologies to understand how these systems improve industrial automation.

Automation

Inspection stations enhance quality control by automating visual and sensor-based checks, reducing human error and boosting production efficiency. Collaborative robots (cobots) integrate seamlessly with human workers to perform repetitive or precise tasks, improving flexibility and safety in automated workflows. Explore how integrating inspection stations with collaborative robots can optimize your manufacturing automation processes.

Source and External Links

Vehicle safety systems inspections - Bureau of Automotive Repair - State-certified stations provide comprehensive vehicle safety inspections, with licensed technicians entering results into the BAR Safety Inspection System and issuing electronic compliance certificates for passing vehicles.

San Jose, CA Vehicle Inspection - Capitol Auto Care - Offers annual, sale, or transfer vehicle inspections following strict guidelines to ensure vehicles are roadworthy and compliant with state regulations, providing a full checklist after service.

Smog Hut Star Station: Smog Check and DMV Registration Services - San Jose - Star Certified Smog Check station specializing in emissions testing for California-registered vehicles, using advanced equipment for fast, accurate results and DMV registration services.

dowidth.com

dowidth.com