Smart dust consists of tiny wireless sensors capable of real-time environmental monitoring and data collection at a microscale, enhancing precision in manufacturing processes. Cyber-physical systems integrate computational algorithms and physical components, enabling advanced automation, control, and seamless communication in industrial environments. Discover how these technologies revolutionize manufacturing efficiency and innovation.

Why it is important

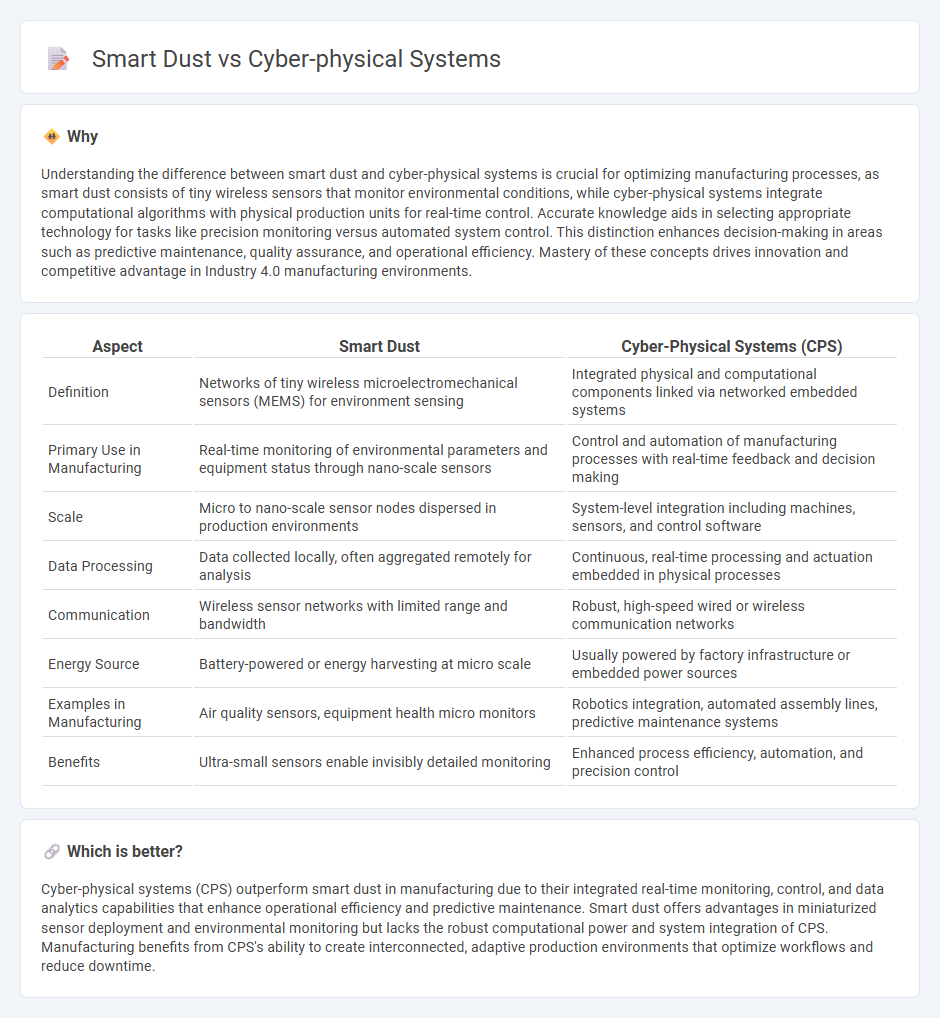

Understanding the difference between smart dust and cyber-physical systems is crucial for optimizing manufacturing processes, as smart dust consists of tiny wireless sensors that monitor environmental conditions, while cyber-physical systems integrate computational algorithms with physical production units for real-time control. Accurate knowledge aids in selecting appropriate technology for tasks like precision monitoring versus automated system control. This distinction enhances decision-making in areas such as predictive maintenance, quality assurance, and operational efficiency. Mastery of these concepts drives innovation and competitive advantage in Industry 4.0 manufacturing environments.

Comparison Table

| Aspect | Smart Dust | Cyber-Physical Systems (CPS) |

|---|---|---|

| Definition | Networks of tiny wireless microelectromechanical sensors (MEMS) for environment sensing | Integrated physical and computational components linked via networked embedded systems |

| Primary Use in Manufacturing | Real-time monitoring of environmental parameters and equipment status through nano-scale sensors | Control and automation of manufacturing processes with real-time feedback and decision making |

| Scale | Micro to nano-scale sensor nodes dispersed in production environments | System-level integration including machines, sensors, and control software |

| Data Processing | Data collected locally, often aggregated remotely for analysis | Continuous, real-time processing and actuation embedded in physical processes |

| Communication | Wireless sensor networks with limited range and bandwidth | Robust, high-speed wired or wireless communication networks |

| Energy Source | Battery-powered or energy harvesting at micro scale | Usually powered by factory infrastructure or embedded power sources |

| Examples in Manufacturing | Air quality sensors, equipment health micro monitors | Robotics integration, automated assembly lines, predictive maintenance systems |

| Benefits | Ultra-small sensors enable invisibly detailed monitoring | Enhanced process efficiency, automation, and precision control |

Which is better?

Cyber-physical systems (CPS) outperform smart dust in manufacturing due to their integrated real-time monitoring, control, and data analytics capabilities that enhance operational efficiency and predictive maintenance. Smart dust offers advantages in miniaturized sensor deployment and environmental monitoring but lacks the robust computational power and system integration of CPS. Manufacturing benefits from CPS's ability to create interconnected, adaptive production environments that optimize workflows and reduce downtime.

Connection

Smart dust, composed of tiny wireless microelectromechanical sensors, integrates seamlessly with cyber-physical systems (CPS) in manufacturing to provide real-time monitoring and data collection across production lines. Cyber-physical systems leverage the granular data from smart dust to enhance automation, predict maintenance needs, and optimize process efficiency through intelligent feedback loops. This synergy drives Industry 4.0 advancements by enabling precise control and adaptive manufacturing environments.

Key Terms

Embedded Sensors

Embedded sensors in cyber-physical systems (CPS) enable real-time data collection, processing, and feedback across interconnected physical and computational components, ensuring seamless integration and control. Smart dust leverages micro-scale embedded sensors dispersed in an environment to monitor conditions like temperature, humidity, or movement with ultra-low power consumption and wireless communication capabilities. Explore how these sensor technologies revolutionize automation and environmental monitoring by diving deeper into their comparative applications.

Real-time Data Processing

Cyber-physical systems integrate computing, networking, and physical processes to enable real-time data processing through embedded sensors and actuators, ensuring immediate response and control. Smart dust involves minuscule sensor networks capable of gathering and relaying environmental data, but often faces constraints in power and processing speed impacting real-time capabilities. Explore the distinct real-time data processing strengths and limitations of these technologies to understand their optimal applications.

Wireless Communication

Cyber-physical systems (CPS) integrate computational algorithms and physical components through wireless communication protocols like Zigbee, Bluetooth, and 5G to enable real-time data exchange and control. Smart dust consists of ultraminiature sensors with autonomous wireless communication capabilities using low-power radio frequencies, optimized for environmental monitoring and pervasive sensing. Explore more to understand their distinct wireless communication technologies and application implications.

Source and External Links

Cyber-Physical Systems (CPS) Explained - Cyber-physical systems model, automate, and control physical mechanisms through deeply integrated digital and physical components, enabling real-time simulation and management via a unified interface.

Cyber-Physical Systems - a Concept Map - CPS merges computation, networking, and physical processes using embedded computers to monitor and control real-world dynamics, with feedback loops connecting physical events and digital responses.

10 Examples of Cyber-Physical Systems - CPS connects the cyber and physical worlds in critical industries like manufacturing and healthcare, differing from IoT by emphasizing tight integration with physical processes, real-time control, and advanced analytics.

dowidth.com

dowidth.com