Condition monitoring focuses on real-time data collection and analysis to detect equipment malfunctions before failures occur, enhancing operational efficiency. Asset management involves the strategic oversight of an organization's physical assets throughout their lifecycle, including procurement, maintenance, and disposal, to maximize value and reduce costs. Explore our detailed guide to understand how integrating condition monitoring with asset management drives smarter manufacturing decisions.

Why it is important

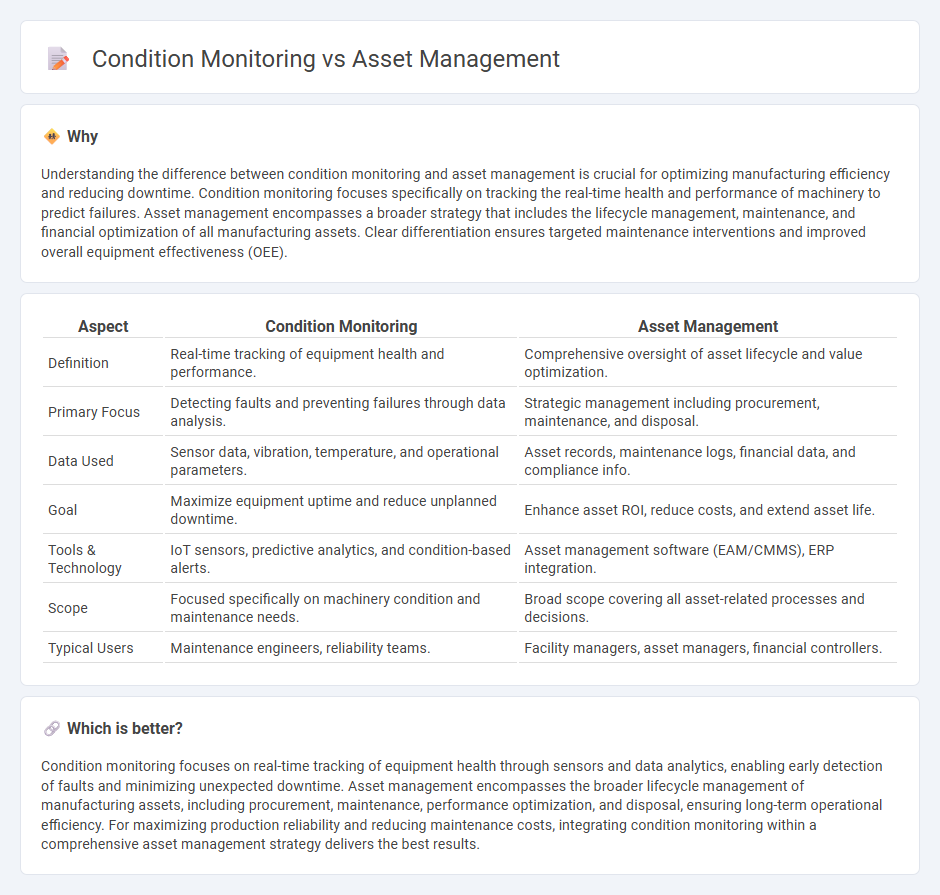

Understanding the difference between condition monitoring and asset management is crucial for optimizing manufacturing efficiency and reducing downtime. Condition monitoring focuses specifically on tracking the real-time health and performance of machinery to predict failures. Asset management encompasses a broader strategy that includes the lifecycle management, maintenance, and financial optimization of all manufacturing assets. Clear differentiation ensures targeted maintenance interventions and improved overall equipment effectiveness (OEE).

Comparison Table

| Aspect | Condition Monitoring | Asset Management |

|---|---|---|

| Definition | Real-time tracking of equipment health and performance. | Comprehensive oversight of asset lifecycle and value optimization. |

| Primary Focus | Detecting faults and preventing failures through data analysis. | Strategic management including procurement, maintenance, and disposal. |

| Data Used | Sensor data, vibration, temperature, and operational parameters. | Asset records, maintenance logs, financial data, and compliance info. |

| Goal | Maximize equipment uptime and reduce unplanned downtime. | Enhance asset ROI, reduce costs, and extend asset life. |

| Tools & Technology | IoT sensors, predictive analytics, and condition-based alerts. | Asset management software (EAM/CMMS), ERP integration. |

| Scope | Focused specifically on machinery condition and maintenance needs. | Broad scope covering all asset-related processes and decisions. |

| Typical Users | Maintenance engineers, reliability teams. | Facility managers, asset managers, financial controllers. |

Which is better?

Condition monitoring focuses on real-time tracking of equipment health through sensors and data analytics, enabling early detection of faults and minimizing unexpected downtime. Asset management encompasses the broader lifecycle management of manufacturing assets, including procurement, maintenance, performance optimization, and disposal, ensuring long-term operational efficiency. For maximizing production reliability and reducing maintenance costs, integrating condition monitoring within a comprehensive asset management strategy delivers the best results.

Connection

Condition monitoring uses sensors and real-time data analytics to assess equipment health, enabling predictive maintenance in manufacturing plants. Asset management integrates this information to optimize asset lifecycle, reduce downtime, and improve operational efficiency. Together, they enhance decision-making by providing actionable insights into machinery performance and maintenance scheduling.

Key Terms

**Asset Management:**

Asset management involves systematic tracking, maintenance scheduling, and lifecycle optimization of physical assets to maximize their value and operational efficiency. It integrates financial, operational, and risk data to ensure assets deliver expected performance while minimizing costs and downtime. Explore how advanced asset management strategies can enhance your organization's resource utilization and long-term profitability.

Lifecycle Costing

Asset management encompasses the strategic oversight and optimization of an asset's entire lifecycle, aiming to reduce total costs and maximize value. Condition monitoring plays a crucial role within asset management by providing real-time data on equipment performance, helping to predict failures and schedule maintenance efficiently, thus lowering lifecycle costing. Explore how integrating condition monitoring into asset management strategies can significantly improve cost efficiency and asset longevity.

Reliability-Centered Maintenance (RCM)

Reliability-Centered Maintenance (RCM) integrates asset management and condition monitoring to optimize equipment reliability, focusing on critical assets' performance and failure modes. Asset management emphasizes lifecycle cost control and strategic decision-making, while condition monitoring provides real-time data on asset health, enabling predictive maintenance and reducing unplanned downtime. Discover how combining these approaches through RCM enhances operational efficiency and extends asset life.

Source and External Links

Asset Management Explained: Key Roles and Benefits - Asset management involves financial institutions managing money for institutional investors by buying, holding, and selling various financial assets like stocks and bonds, acting as fiduciaries responsible for their clients' best interests.

Asset management - Wikipedia - Asset management is a systematic process of developing, operating, maintaining, upgrading, and disposing of tangible and intangible assets in the most cost-effective manner, encompassing both financial investment management and physical asset governance.

Brookfield Asset Management (BAM) - Brookfield Asset Management is a global alternative asset manager with over $1 trillion in assets under management across sectors like renewable power, infrastructure, private equity, and real estate, focusing on long-term risk-adjusted returns.

dowidth.com

dowidth.com