Adaptive machining leverages real-time data and flexible controls to adjust processes dynamically, enhancing precision and reducing downtime in manufacturing operations. Hard automation relies on fixed programming and dedicated equipment for high-volume production but lacks the flexibility needed for custom or small-batch jobs. Explore the advantages and applications of both approaches to optimize your manufacturing strategy.

Why it is important

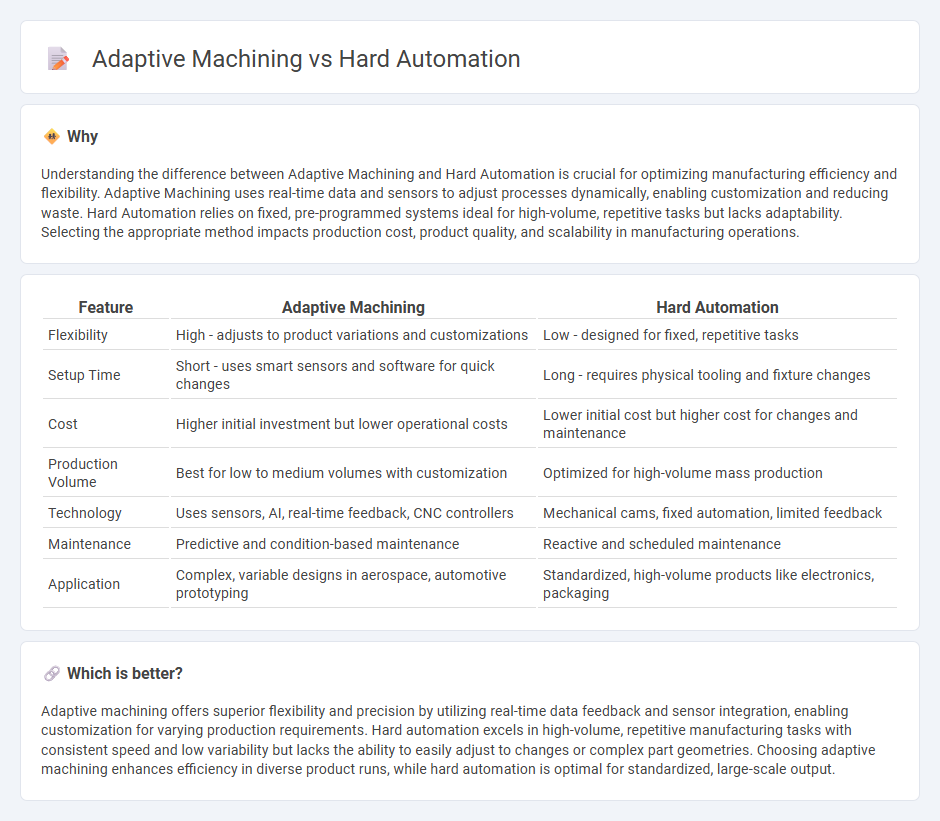

Understanding the difference between Adaptive Machining and Hard Automation is crucial for optimizing manufacturing efficiency and flexibility. Adaptive Machining uses real-time data and sensors to adjust processes dynamically, enabling customization and reducing waste. Hard Automation relies on fixed, pre-programmed systems ideal for high-volume, repetitive tasks but lacks adaptability. Selecting the appropriate method impacts production cost, product quality, and scalability in manufacturing operations.

Comparison Table

| Feature | Adaptive Machining | Hard Automation |

|---|---|---|

| Flexibility | High - adjusts to product variations and customizations | Low - designed for fixed, repetitive tasks |

| Setup Time | Short - uses smart sensors and software for quick changes | Long - requires physical tooling and fixture changes |

| Cost | Higher initial investment but lower operational costs | Lower initial cost but higher cost for changes and maintenance |

| Production Volume | Best for low to medium volumes with customization | Optimized for high-volume mass production |

| Technology | Uses sensors, AI, real-time feedback, CNC controllers | Mechanical cams, fixed automation, limited feedback |

| Maintenance | Predictive and condition-based maintenance | Reactive and scheduled maintenance |

| Application | Complex, variable designs in aerospace, automotive prototyping | Standardized, high-volume products like electronics, packaging |

Which is better?

Adaptive machining offers superior flexibility and precision by utilizing real-time data feedback and sensor integration, enabling customization for varying production requirements. Hard automation excels in high-volume, repetitive manufacturing tasks with consistent speed and low variability but lacks the ability to easily adjust to changes or complex part geometries. Choosing adaptive machining enhances efficiency in diverse product runs, while hard automation is optimal for standardized, large-scale output.

Connection

Adaptive machining enhances manufacturing efficiency by continuously monitoring and adjusting processes to accommodate variations in material and tool conditions, while hard automation relies on fixed, dedicated equipment designed for repetitive tasks. The integration of adaptive machining technologies into hard automation systems allows manufacturers to improve precision and reduce downtime by enabling real-time adjustments within rigid automated setups. This connection drives higher production quality and operational flexibility in mass manufacturing environments.

Key Terms

Fixed tooling

Fixed tooling in hard automation offers high precision and repeatability for mass production with minimal variation, optimizing efficiency in structured manufacturing environments. Adaptive machining integrates sensors and real-time adjustments, enhancing flexibility while maintaining accuracy despite changing conditions or material inconsistencies. Discover how fixed tooling and adaptive machining compare in boosting productivity and quality across diverse industrial applications.

Flexibility

Hard automation offers limited flexibility due to its fixed programming and setup, making it ideal for high-volume, repetitive tasks but less adaptable to product variations. Adaptive machining leverages real-time data and AI-driven controls to adjust processes dynamically, enhancing flexibility for custom or low-volume manufacturing. Discover how adaptive machining revolutionizes production efficiency with unmatched versatility.

Programmable control

Hard automation relies on fixed, programmable control systems designed for high-volume production with repetitive tasks, offering limited flexibility and rapid cycle times. Adaptive machining utilizes advanced programmable control integrated with real-time sensors and AI algorithms to adjust machining parameters dynamically, enhancing precision and accommodating varying workpiece conditions. Explore the differences in programmable control between hard automation and adaptive machining to optimize manufacturing efficiency.

Source and External Links

Hard Automation vs. Soft Automation: Which is Best? - 9to5flow - Hard automation uses specialized, fixed equipment for specific tasks, ideal for high-volume production with high precision and less flexibility, requiring significant initial capital investment.

6 Types of Automation: Benefits, Pros/Cons, Examples - Hard automation, also called fixed automation, is best for repetitive, large-volume production of identical units, offering high production rates and consistent quality but requiring high upfront costs and limited adaptability.

Types of Automation | UTI - Universal Technical Institute - Hard automation is fixed automation designed for high-volume, repetitive tasks with specialized equipment, offering efficiency and low unit costs but with low flexibility and high setup costs.

dowidth.com

dowidth.com