Collaborative robots (cobots) enhance manufacturing flexibility by working safely alongside human operators to perform tasks such as assembly and quality inspection, while automated guided vehicles (AGVs) optimize material handling through autonomous navigation and transportation within factory floors. Cobots increase productivity by adapting to diverse applications with ease, whereas AGVs streamline logistics by reducing manual labor and minimizing errors in inventory movement. Discover how integrating cobots and AGVs can revolutionize your manufacturing processes.

Why it is important

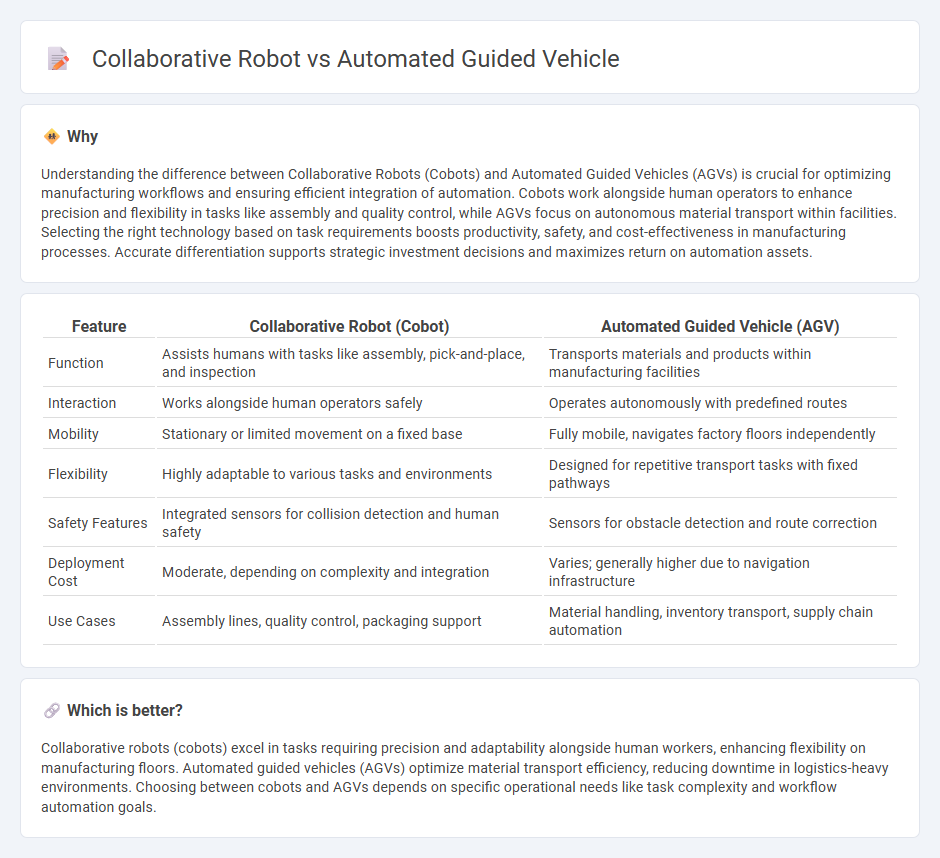

Understanding the difference between Collaborative Robots (Cobots) and Automated Guided Vehicles (AGVs) is crucial for optimizing manufacturing workflows and ensuring efficient integration of automation. Cobots work alongside human operators to enhance precision and flexibility in tasks like assembly and quality control, while AGVs focus on autonomous material transport within facilities. Selecting the right technology based on task requirements boosts productivity, safety, and cost-effectiveness in manufacturing processes. Accurate differentiation supports strategic investment decisions and maximizes return on automation assets.

Comparison Table

| Feature | Collaborative Robot (Cobot) | Automated Guided Vehicle (AGV) |

|---|---|---|

| Function | Assists humans with tasks like assembly, pick-and-place, and inspection | Transports materials and products within manufacturing facilities |

| Interaction | Works alongside human operators safely | Operates autonomously with predefined routes |

| Mobility | Stationary or limited movement on a fixed base | Fully mobile, navigates factory floors independently |

| Flexibility | Highly adaptable to various tasks and environments | Designed for repetitive transport tasks with fixed pathways |

| Safety Features | Integrated sensors for collision detection and human safety | Sensors for obstacle detection and route correction |

| Deployment Cost | Moderate, depending on complexity and integration | Varies; generally higher due to navigation infrastructure |

| Use Cases | Assembly lines, quality control, packaging support | Material handling, inventory transport, supply chain automation |

Which is better?

Collaborative robots (cobots) excel in tasks requiring precision and adaptability alongside human workers, enhancing flexibility on manufacturing floors. Automated guided vehicles (AGVs) optimize material transport efficiency, reducing downtime in logistics-heavy environments. Choosing between cobots and AGVs depends on specific operational needs like task complexity and workflow automation goals.

Connection

Collaborative robots (cobots) and Automated Guided Vehicles (AGVs) are connected through their integrated roles in modern manufacturing environments, enhancing automation and efficiency. Cobots perform precise, flexible tasks alongside human workers, while AGVs handle material transport and logistics within facilities. Their synchronization enables seamless workflows, reducing downtime and optimizing production cycles.

Key Terms

Navigation System

Automated guided vehicles (AGVs) rely on fixed path navigation systems such as magnetic tape or laser guidance for precise route adherence, enabling efficient material transport in industrial settings. In contrast, collaborative robots (cobots) utilize advanced sensor fusion, computer vision, and AI algorithms to dynamically navigate and adapt to changing environments alongside human workers. Discover more about how these navigation systems impact operational efficiency and safety in modern manufacturing.

Human-Robot Interaction

Automated guided vehicles (AGVs) navigate predefined paths independently, minimizing human intervention, while collaborative robots (cobots) operate alongside humans, enhancing safety and efficiency through direct interaction. Human-robot interaction in cobots involves intuitive interfaces and real-time responsiveness, fostering seamless teamwork, whereas AGVs rely on sensors and programmed routes to avoid disruptions. Explore in-depth insights on optimizing human-robot collaboration for industrial applications.

Flexibility

Automated guided vehicles (AGVs) offer predefined route flexibility suitable for repetitive material transport, while collaborative robots (cobots) excel in adaptive task execution with dynamic workspace interaction. Cobots provide superior versatility in handling diverse operations, adjusting to varying production needs without extensive reprogramming. Discover how these technologies can optimize your workflow by exploring their unique flexibility features in depth.

Source and External Links

What Are Automated Guided Vehicles (AGVs)? - Spectra by MHI - Automated guided vehicles (AGVs) are autonomous, driverless machines that transport materials within facilities like warehouses and factories using internal navigation systems and central control software to improve efficiency and address labor shortages.

AGV Manufacturers | AGV Suppliers | Automatic Guided ... - AI is revolutionizing AGVs by enabling dynamic navigation, predictive maintenance, multi-task capabilities, and human-robot collaboration, marking a shift from fixed paths to flexible, intelligent autonomous vehicles expected to dominate by 2030.

What is an AGV: The comprehensive guide - AGVs are sophisticated autonomous vehicles designed for industrial material transport, operating on predefined paths using various navigation technologies, and have evolved into a cornerstone of automation across industries due to their precision and reliability.

dowidth.com

dowidth.com