Digital thread integrates data flow seamlessly across the entire manufacturing lifecycle, enabling real-time tracking and traceability of products from design to delivery. Industry 4.0 encompasses broader smart manufacturing technologies such as IoT, AI, and automation to enhance production efficiency and flexibility. Explore how these concepts interconnect to drive innovation and productivity in modern manufacturing.

Why it is important

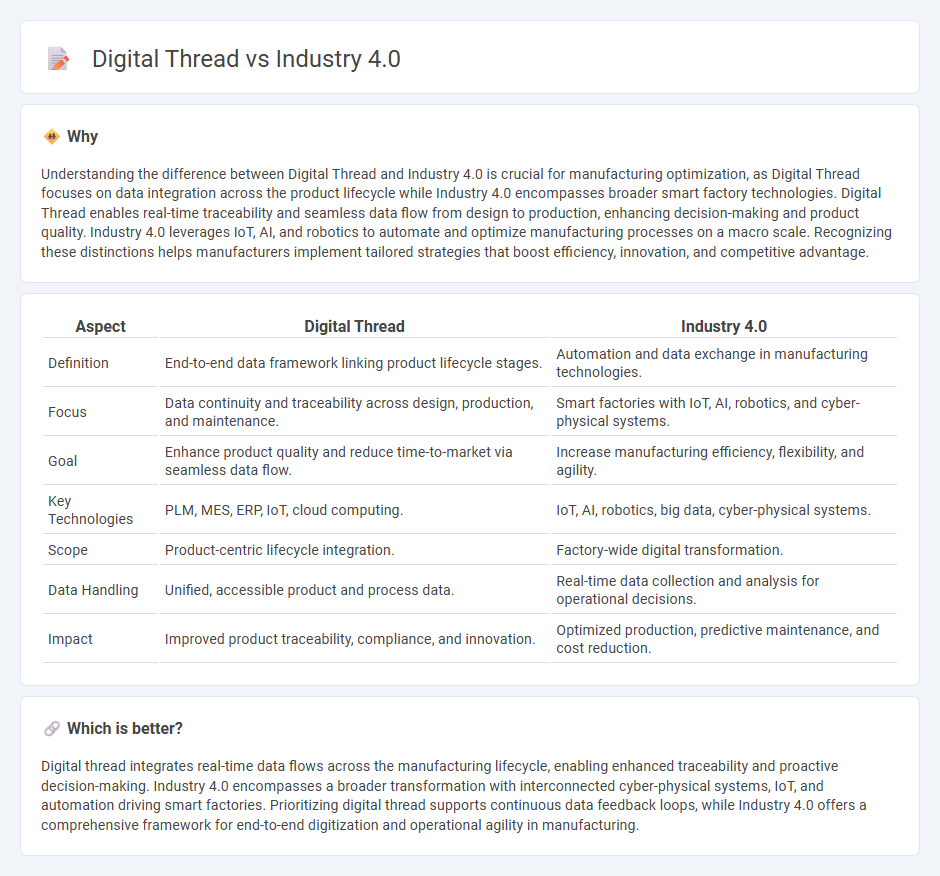

Understanding the difference between Digital Thread and Industry 4.0 is crucial for manufacturing optimization, as Digital Thread focuses on data integration across the product lifecycle while Industry 4.0 encompasses broader smart factory technologies. Digital Thread enables real-time traceability and seamless data flow from design to production, enhancing decision-making and product quality. Industry 4.0 leverages IoT, AI, and robotics to automate and optimize manufacturing processes on a macro scale. Recognizing these distinctions helps manufacturers implement tailored strategies that boost efficiency, innovation, and competitive advantage.

Comparison Table

| Aspect | Digital Thread | Industry 4.0 |

|---|---|---|

| Definition | End-to-end data framework linking product lifecycle stages. | Automation and data exchange in manufacturing technologies. |

| Focus | Data continuity and traceability across design, production, and maintenance. | Smart factories with IoT, AI, robotics, and cyber-physical systems. |

| Goal | Enhance product quality and reduce time-to-market via seamless data flow. | Increase manufacturing efficiency, flexibility, and agility. |

| Key Technologies | PLM, MES, ERP, IoT, cloud computing. | IoT, AI, robotics, big data, cyber-physical systems. |

| Scope | Product-centric lifecycle integration. | Factory-wide digital transformation. |

| Data Handling | Unified, accessible product and process data. | Real-time data collection and analysis for operational decisions. |

| Impact | Improved product traceability, compliance, and innovation. | Optimized production, predictive maintenance, and cost reduction. |

Which is better?

Digital thread integrates real-time data flows across the manufacturing lifecycle, enabling enhanced traceability and proactive decision-making. Industry 4.0 encompasses a broader transformation with interconnected cyber-physical systems, IoT, and automation driving smart factories. Prioritizing digital thread supports continuous data feedback loops, while Industry 4.0 offers a comprehensive framework for end-to-end digitization and operational agility in manufacturing.

Connection

Digital thread integrates data flow across the entire manufacturing lifecycle, enabling real-time visibility and traceability from design to production and service. Industry 4.0 leverages this interconnected digital framework by incorporating IoT, AI, and cyber-physical systems to optimize manufacturing processes and enhance operational efficiency. The synergy between digital thread and Industry 4.0 drives smart factories through seamless data exchange and predictive analytics, boosting productivity and reducing downtime.

Key Terms

**Industry 4.0:**

Industry 4.0 integrates cyber-physical systems, IoT, and cloud computing to create smart factories with automated and interconnected manufacturing processes. It emphasizes real-time data exchange and decentralized decision-making to optimize production efficiency and reduce downtime. Discover how Industry 4.0 transforms traditional manufacturing into intelligent, highly responsive environments.

Cyber-Physical Systems

Industry 4.0 integrates Cyber-Physical Systems (CPS) to create smart factories where physical processes are closely monitored and controlled through digital networks. The digital thread complements this by providing a seamless flow of data across the entire product lifecycle, enhancing traceability and decision-making. Explore how Cyber-Physical Systems drive innovation within Industry 4.0 and the role of the digital thread in connecting digital and physical realms.

Industrial Internet of Things (IIoT)

Industry 4.0 integrates smart manufacturing technologies, leveraging the Industrial Internet of Things (IIoT) to enable real-time data exchange and automation across production systems. The digital thread complements this by providing a seamless flow of data throughout the product lifecycle, from design to operations, enhancing traceability and decision-making. Explore how combining Industry 4.0 and the digital thread transforms IIoT-driven industrial processes for optimized efficiency.

Source and External Links

Industry 4.0 vs 5.0: What's the Difference? - Industry 4.0, also called the Fourth Industrial Revolution, is marked by the rise of digital industrial technologies like cyber-physical systems, enabling innovative collaboration between humans and machines to create smart, integrated factories using data-driven insights.

What is Industry 4.0? - Industry 4.0 represents the digital transformation in manufacturing through IoT, AI, cloud computing, and advanced sensors, facilitating real-time decision making, predictive maintenance, and greater efficiency in smart factories.

What is Industry 4.0--the Industrial Internet of Things (IIoT)? - Industry 4.0 is a new Industrial Revolution phase emphasizing interconnectivity, automation, machine learning, and real-time data to create a connected and intelligent manufacturing ecosystem that transforms business operations and growth.

dowidth.com

dowidth.com