Machine vision systems utilize advanced cameras and image processing algorithms to inspect and analyze products in manufacturing lines with high precision and speed. Barcode scanning relies on optical recognition of printed codes to track inventory and streamline logistics but offers limited inspection capabilities compared to machine vision. Explore the advantages and applications of both technologies to optimize manufacturing efficiency and quality control.

Why it is important

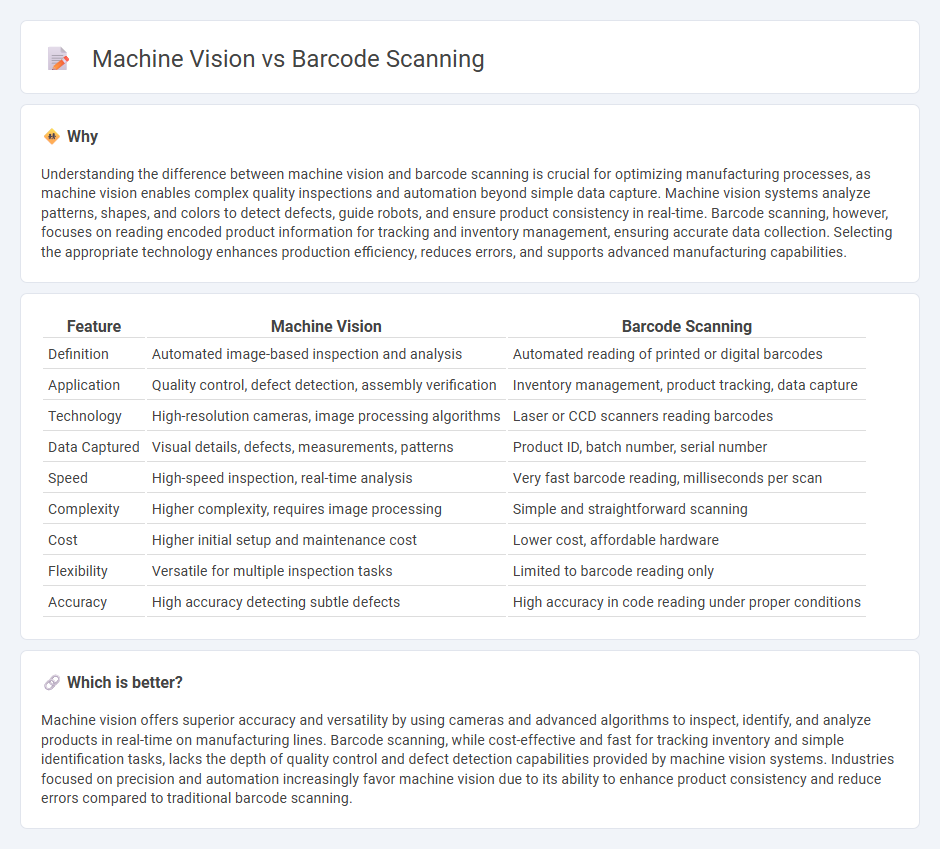

Understanding the difference between machine vision and barcode scanning is crucial for optimizing manufacturing processes, as machine vision enables complex quality inspections and automation beyond simple data capture. Machine vision systems analyze patterns, shapes, and colors to detect defects, guide robots, and ensure product consistency in real-time. Barcode scanning, however, focuses on reading encoded product information for tracking and inventory management, ensuring accurate data collection. Selecting the appropriate technology enhances production efficiency, reduces errors, and supports advanced manufacturing capabilities.

Comparison Table

| Feature | Machine Vision | Barcode Scanning |

|---|---|---|

| Definition | Automated image-based inspection and analysis | Automated reading of printed or digital barcodes |

| Application | Quality control, defect detection, assembly verification | Inventory management, product tracking, data capture |

| Technology | High-resolution cameras, image processing algorithms | Laser or CCD scanners reading barcodes |

| Data Captured | Visual details, defects, measurements, patterns | Product ID, batch number, serial number |

| Speed | High-speed inspection, real-time analysis | Very fast barcode reading, milliseconds per scan |

| Complexity | Higher complexity, requires image processing | Simple and straightforward scanning |

| Cost | Higher initial setup and maintenance cost | Lower cost, affordable hardware |

| Flexibility | Versatile for multiple inspection tasks | Limited to barcode reading only |

| Accuracy | High accuracy detecting subtle defects | High accuracy in code reading under proper conditions |

Which is better?

Machine vision offers superior accuracy and versatility by using cameras and advanced algorithms to inspect, identify, and analyze products in real-time on manufacturing lines. Barcode scanning, while cost-effective and fast for tracking inventory and simple identification tasks, lacks the depth of quality control and defect detection capabilities provided by machine vision systems. Industries focused on precision and automation increasingly favor machine vision due to its ability to enhance product consistency and reduce errors compared to traditional barcode scanning.

Connection

Machine vision and barcode scanning are integral components of automated manufacturing systems, enabling precise identification and quality control of products. Machine vision systems capture high-resolution images to interpret barcode data, ensuring accurate product tracking and inventory management. Integrating machine vision with barcode scanning optimizes production line efficiency, reduces errors, and enhances real-time data collection in manufacturing processes.

Key Terms

Data Capture

Barcode scanning specializes in capturing encoded data from printed barcodes using laser or camera-based readers, ensuring rapid and accurate data retrieval for inventory, retail, and logistics applications. Machine vision extends beyond simple data capture by analyzing images for patterns, shapes, and colors, enabling complex inspection, measurement, and identification tasks in manufacturing and automation environments. Explore the differences in data capture capabilities to determine the optimal solution for your operational needs.

Quality Inspection

Barcode scanning offers fast, reliable product identification by reading printed codes, effectively streamlining inventory and logistics processes. Machine vision enhances quality inspection through detailed image analysis, detecting defects, measuring dimensions, and verifying assembly accuracy with high precision. Explore how integrating these technologies can revolutionize your quality control systems.

Automation

Barcode scanning automates data collection by quickly reading printed barcodes, enhancing inventory accuracy and speeding up checkout processes. Machine vision extends automation capabilities through image analysis, enabling defect detection, quality control, and robotic guidance in manufacturing environments. Explore how integrating barcode scanning and machine vision can revolutionize your automation strategy.

Source and External Links

Scan Barcodes - My QR Code - Quickly scan any common barcode format using your device's camera or by uploading an image, with instant results displayed on the page.

QR & Barcode Scanner - Apps on Google Play - A free, full-featured Android app for scanning QR codes and barcodes, comparing prices, sharing data, and creating custom QR codes.

QR & Barcode Reader - Apps on Google Play - Scan QR codes and barcodes to fetch product details, connect to Wi-Fi, add calendar events, and enjoy secure browsing with support for major online retailers--all without unnecessary permissions.

dowidth.com

dowidth.com