Lights out factories operate autonomously without human presence, leveraging advanced robotics and AI to maintain continuous production, maximizing efficiency and minimizing errors. Computer-Integrated Manufacturing (CIM) integrates various automated processes through centralized computer control, enhancing flexibility and data-driven decision-making in production lines. Explore the benefits and challenges of these manufacturing approaches to optimize your industrial operations.

Why it is important

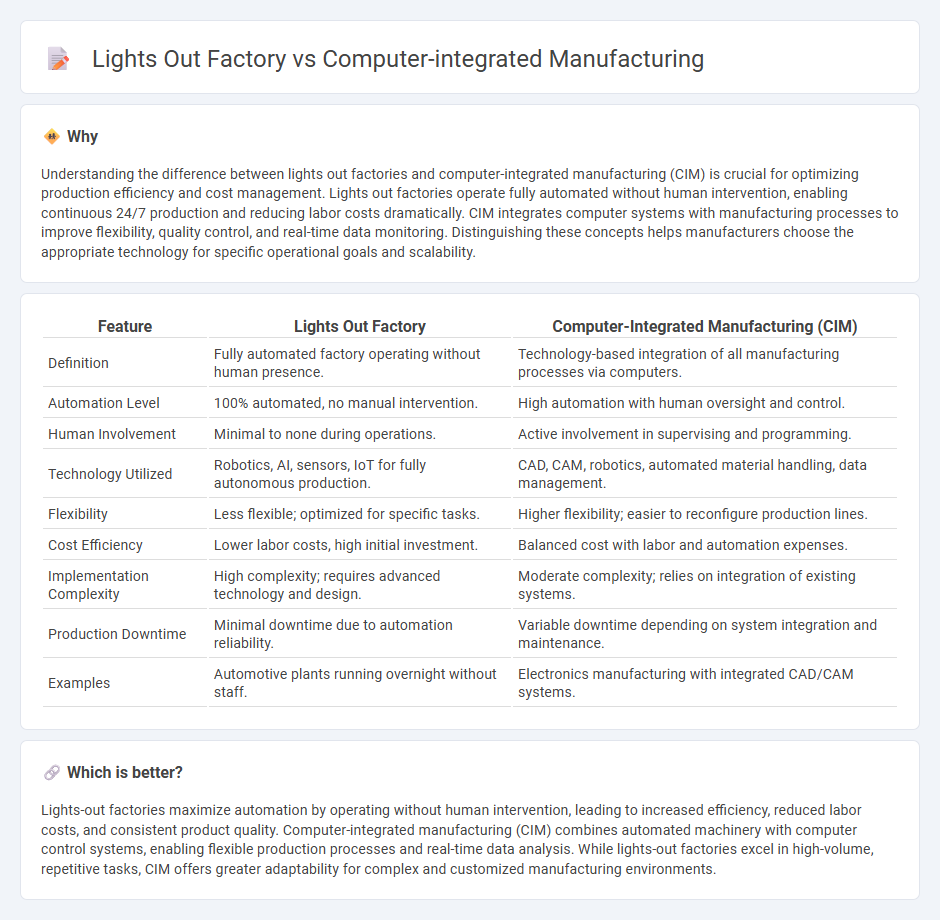

Understanding the difference between lights out factories and computer-integrated manufacturing (CIM) is crucial for optimizing production efficiency and cost management. Lights out factories operate fully automated without human intervention, enabling continuous 24/7 production and reducing labor costs dramatically. CIM integrates computer systems with manufacturing processes to improve flexibility, quality control, and real-time data monitoring. Distinguishing these concepts helps manufacturers choose the appropriate technology for specific operational goals and scalability.

Comparison Table

| Feature | Lights Out Factory | Computer-Integrated Manufacturing (CIM) |

|---|---|---|

| Definition | Fully automated factory operating without human presence. | Technology-based integration of all manufacturing processes via computers. |

| Automation Level | 100% automated, no manual intervention. | High automation with human oversight and control. |

| Human Involvement | Minimal to none during operations. | Active involvement in supervising and programming. |

| Technology Utilized | Robotics, AI, sensors, IoT for fully autonomous production. | CAD, CAM, robotics, automated material handling, data management. |

| Flexibility | Less flexible; optimized for specific tasks. | Higher flexibility; easier to reconfigure production lines. |

| Cost Efficiency | Lower labor costs, high initial investment. | Balanced cost with labor and automation expenses. |

| Implementation Complexity | High complexity; requires advanced technology and design. | Moderate complexity; relies on integration of existing systems. |

| Production Downtime | Minimal downtime due to automation reliability. | Variable downtime depending on system integration and maintenance. |

| Examples | Automotive plants running overnight without staff. | Electronics manufacturing with integrated CAD/CAM systems. |

Which is better?

Lights-out factories maximize automation by operating without human intervention, leading to increased efficiency, reduced labor costs, and consistent product quality. Computer-integrated manufacturing (CIM) combines automated machinery with computer control systems, enabling flexible production processes and real-time data analysis. While lights-out factories excel in high-volume, repetitive tasks, CIM offers greater adaptability for complex and customized manufacturing environments.

Connection

Lights-out factories leverage computer-integrated manufacturing (CIM) systems to enable fully automated production without human intervention, using robotics, sensors, and AI for continuous operation. CIM integrates various manufacturing processes through computer control, ensuring precision and real-time data communication crucial for lights-out efficiency. This synergy reduces downtime, enhances productivity, and minimizes errors by synchronizing design, production, and quality control workflows.

Key Terms

**Computer-Integrated Manufacturing:**

Computer-Integrated Manufacturing (CIM) integrates advanced software systems with automated machinery to streamline production processes, enhance precision, and reduce human error. It encompasses design, analysis, planning, purchasing, cost accounting, inventory control, and distribution within a unified digital environment. Explore our detailed insights on how CIM revolutionizes manufacturing efficiency and competitiveness.

CAD/CAM

Computer-integrated manufacturing (CIM) leverages CAD/CAM systems to streamline design and production processes, enabling seamless data transfer between product design and manufacturing. Lights-out factories utilize these advanced CAD/CAM technologies for fully automated operations with minimal human intervention, maximizing efficiency and precision. Explore how CAD/CAM innovations drive the evolution from CIM to fully autonomous lights-out manufacturing environments.

Process Automation

Computer-integrated manufacturing (CIM) employs advanced software systems to automate and control production processes, integrating design, planning, and manufacturing operations for increased efficiency and reduced human error. Lights out factories represent an evolution of CIM, operating fully autonomously without human intervention, utilizing robotics and artificial intelligence to maintain continuous, uninterrupted production cycles. Explore the differences and benefits of these process automation technologies to optimize manufacturing workflows.

Source and External Links

CIM Meaning - Computer Integrated Manufacturing (CIM) is an automated and streamlined manufacturing approach that integrates computer systems from design (CAD) through production (CAM, CNC machines) and real-time control (PLCs) to improve efficiency and product quality.

Computer-integrated manufacturing - CIM involves using computers to control the entire production process by linking engineering, production, and enterprise functions for faster, less error-prone manufacturing through information exchange and closed-loop control.

Computer-Integrated Manufacturing (CIM): Automation & Control - CIM comprises elements like CAD, CAM, production control, quality assurance, inventory management, and predictive maintenance to automate and integrate manufacturing processes for enhanced efficiency and competitiveness.

dowidth.com

dowidth.com