Generative design leverages artificial intelligence and algorithms to produce multiple design solutions based on specified parameters, optimizing for performance, cost, and materials. Rule-based design follows predefined rules and constraints, ensuring designs comply with established standards but often limiting creativity and adaptability. Explore these methodologies to understand how they transform manufacturing innovation and efficiency.

Why it is important

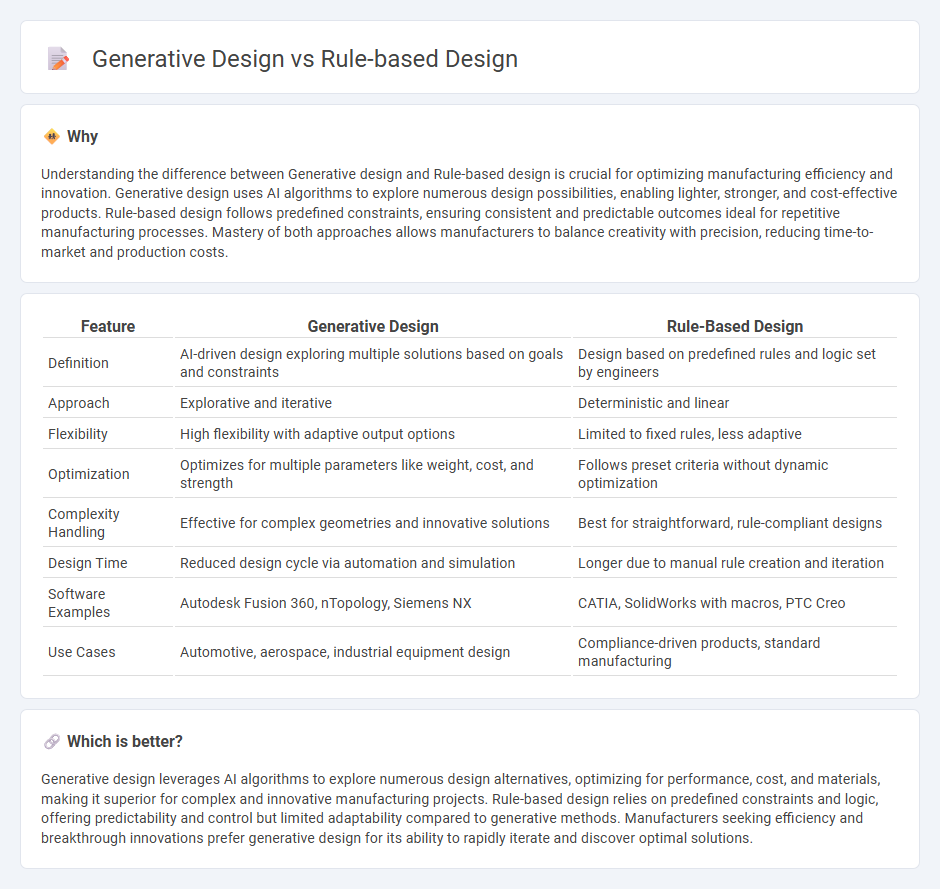

Understanding the difference between Generative design and Rule-based design is crucial for optimizing manufacturing efficiency and innovation. Generative design uses AI algorithms to explore numerous design possibilities, enabling lighter, stronger, and cost-effective products. Rule-based design follows predefined constraints, ensuring consistent and predictable outcomes ideal for repetitive manufacturing processes. Mastery of both approaches allows manufacturers to balance creativity with precision, reducing time-to-market and production costs.

Comparison Table

| Feature | Generative Design | Rule-Based Design |

|---|---|---|

| Definition | AI-driven design exploring multiple solutions based on goals and constraints | Design based on predefined rules and logic set by engineers |

| Approach | Explorative and iterative | Deterministic and linear |

| Flexibility | High flexibility with adaptive output options | Limited to fixed rules, less adaptive |

| Optimization | Optimizes for multiple parameters like weight, cost, and strength | Follows preset criteria without dynamic optimization |

| Complexity Handling | Effective for complex geometries and innovative solutions | Best for straightforward, rule-compliant designs |

| Design Time | Reduced design cycle via automation and simulation | Longer due to manual rule creation and iteration |

| Software Examples | Autodesk Fusion 360, nTopology, Siemens NX | CATIA, SolidWorks with macros, PTC Creo |

| Use Cases | Automotive, aerospace, industrial equipment design | Compliance-driven products, standard manufacturing |

Which is better?

Generative design leverages AI algorithms to explore numerous design alternatives, optimizing for performance, cost, and materials, making it superior for complex and innovative manufacturing projects. Rule-based design relies on predefined constraints and logic, offering predictability and control but limited adaptability compared to generative methods. Manufacturers seeking efficiency and breakthrough innovations prefer generative design for its ability to rapidly iterate and discover optimal solutions.

Connection

Generative design and rule-based design are connected through their shared goal of optimizing manufacturing processes by automating design iterations based on predefined parameters and constraints. While generative design uses AI algorithms to explore a vast design space for optimal solutions, rule-based design applies specific rules to guide the design process within established manufacturing guidelines. Integrating both approaches enhances efficiency, reduces errors, and accelerates product development cycles in advanced manufacturing environments.

Key Terms

Constraints

Rule-based design relies on predefined constraints and explicit parameters set by designers, ensuring consistent and predictable outcomes within established guidelines. Generative design leverages algorithmic processes and AI to explore vast constraint combinations, optimizing solutions that might not be instantly apparent to humans. Discover how constraint management differentiates these approaches and impacts innovation.

Automation

Rule-based design automates processes by following predefined criteria and constraints, ensuring consistency and efficiency in repetitive tasks. Generative design leverages AI and algorithms to explore a vast solution space, producing innovative and optimized designs beyond human intuition. Discover how each approach transforms automation in design workflows.

Optimization

Rule-based design relies on predefined constraints and parameters to optimize solutions within fixed boundaries, ensuring predictable outcomes and efficiency in manufacturing processes. Generative design uses AI and algorithms to explore numerous configurations, optimizing for multiple objectives such as weight, strength, and cost while innovating beyond traditional limitations. Discover how combining these approaches can elevate your design optimization strategies to new heights.

Source and External Links

Rules Engine Design Pattern: A Comprehensive Guide - Nected - This approach centralizes and manages business rules within systems, allowing dynamic rule changes without modifying core application code for enhanced flexibility and scalability in decision-making processes.

Rules Engine Pattern - DevIQ - A behavioral design pattern enabling separation of complex business rules from application logic, improving maintainability, adaptability, and centralized management by encapsulating rules evaluation and execution.

Rule-Based System in AI - GeeksforGeeks - Rule-based systems in AI use explicit rules to model knowledge and reasoning through forward or backward chaining, often applied in expert systems and decision-making applications.

dowidth.com

dowidth.com