Decentralized manufacturing distributes production across multiple sites, enhancing flexibility, reducing transportation costs, and enabling faster response to local market demands. Centralized manufacturing consolidates operations into a single or limited number of large facilities, optimizing economies of scale, streamlining quality control, and simplifying management. Explore the benefits and challenges of each approach to determine the best manufacturing strategy for your business needs.

Why it is important

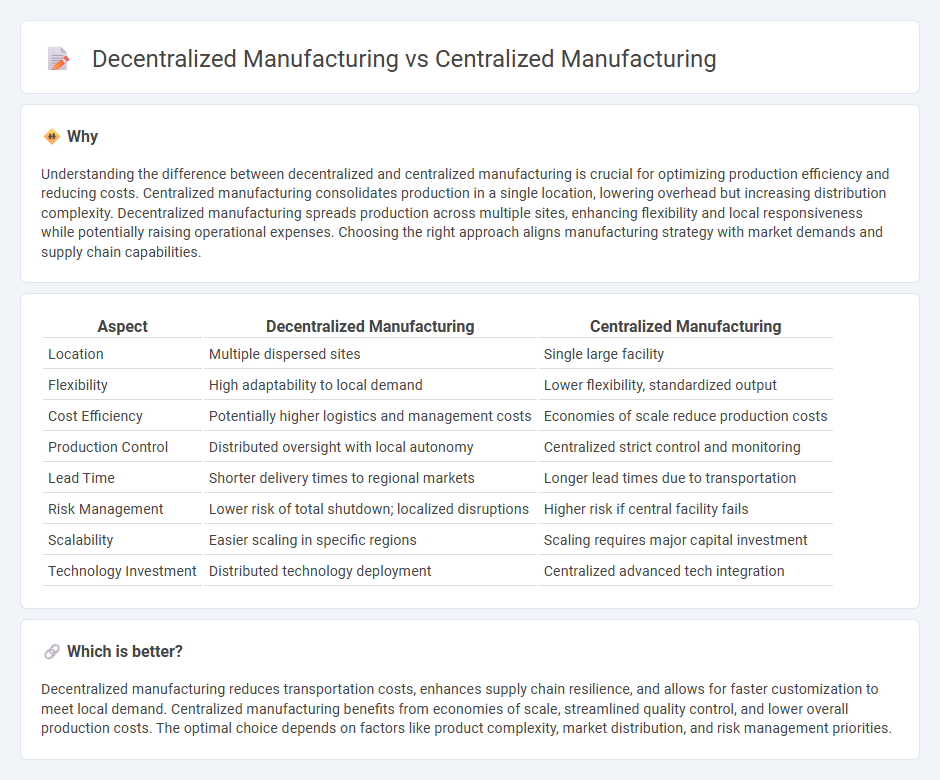

Understanding the difference between decentralized and centralized manufacturing is crucial for optimizing production efficiency and reducing costs. Centralized manufacturing consolidates production in a single location, lowering overhead but increasing distribution complexity. Decentralized manufacturing spreads production across multiple sites, enhancing flexibility and local responsiveness while potentially raising operational expenses. Choosing the right approach aligns manufacturing strategy with market demands and supply chain capabilities.

Comparison Table

| Aspect | Decentralized Manufacturing | Centralized Manufacturing |

|---|---|---|

| Location | Multiple dispersed sites | Single large facility |

| Flexibility | High adaptability to local demand | Lower flexibility, standardized output |

| Cost Efficiency | Potentially higher logistics and management costs | Economies of scale reduce production costs |

| Production Control | Distributed oversight with local autonomy | Centralized strict control and monitoring |

| Lead Time | Shorter delivery times to regional markets | Longer lead times due to transportation |

| Risk Management | Lower risk of total shutdown; localized disruptions | Higher risk if central facility fails |

| Scalability | Easier scaling in specific regions | Scaling requires major capital investment |

| Technology Investment | Distributed technology deployment | Centralized advanced tech integration |

Which is better?

Decentralized manufacturing reduces transportation costs, enhances supply chain resilience, and allows for faster customization to meet local demand. Centralized manufacturing benefits from economies of scale, streamlined quality control, and lower overall production costs. The optimal choice depends on factors like product complexity, market distribution, and risk management priorities.

Connection

Decentralized manufacturing leverages multiple localized production units, enhancing flexibility and reducing lead times, while centralized manufacturing consolidates operations to optimize economies of scale and quality control. Integration of both approaches allows companies to balance cost efficiency with responsiveness to market demands by strategically distributing production tasks. Advanced technologies such as IoT and AI enable seamless coordination between decentralized sites and central hubs, optimizing resource allocation and supply chain management.

Key Terms

Supply Chain

Centralized manufacturing optimizes economies of scale by producing goods at a single or limited number of facilities, reducing production costs but potentially increasing lead times and transportation expenses within the supply chain. Decentralized manufacturing distributes production across multiple locations closer to end markets, enhancing responsiveness, reducing shipment times, and improving supply chain resilience against disruptions. Explore how these strategies impact supply chain efficiency and cost-effectiveness in diverse industries.

Production Control

Centralized manufacturing streamlines production control by consolidating decision-making and oversight within a single location, optimizing resource allocation and consistent quality standards. Decentralized manufacturing distributes control across multiple sites, enhancing flexibility and responsiveness to local market demands while potentially increasing complexity in coordination. Explore how these production control strategies impact efficiency, cost, and scalability to determine the best fit for your business needs.

Scalability

Centralized manufacturing enables streamlined operations and cost efficiencies at scale by consolidating production facilities, optimizing resource allocation, and standardizing processes across a single location. Decentralized manufacturing improves scalability by allowing faster market response, greater flexibility, and localized adaptation, reducing transportation costs and mitigating supply chain risks. Explore how different manufacturing strategies impact scalability and operational agility to determine the best fit for your business growth goals.

Source and External Links

Centralized vs. Decentralized Manufacturing - Katana Cloud Inventory - Centralized manufacturing is a production model where all manufacturing processes occur in one location, enabling better quality control, economies of scale, efficient resource use, and simplified supply chain management.

Centralized vs Decentralized Manufacturing - Uphance - Centralized manufacturing concentrates production in one or a few main facilities to achieve high-volume production, consistent quality, streamlined management, and cost savings through economies of scale.

What is Centralization of Production? - SeeBiz - Centralized production manages all manufacturing and inventory at a single location or under unified control, improving capital control, quality assurance, decision-making efficiency, and infrastructure scalability.

dowidth.com

dowidth.com