Lights-out manufacturing operates with fully automated processes that require no human presence, enhancing efficiency and reducing labor costs. Smart manufacturing integrates advanced technologies like IoT, AI, and data analytics to optimize production, improve quality, and enable real-time decision-making. Explore the key differences and benefits of lights-out versus smart manufacturing to discover the best approach for your facility.

Why it is important

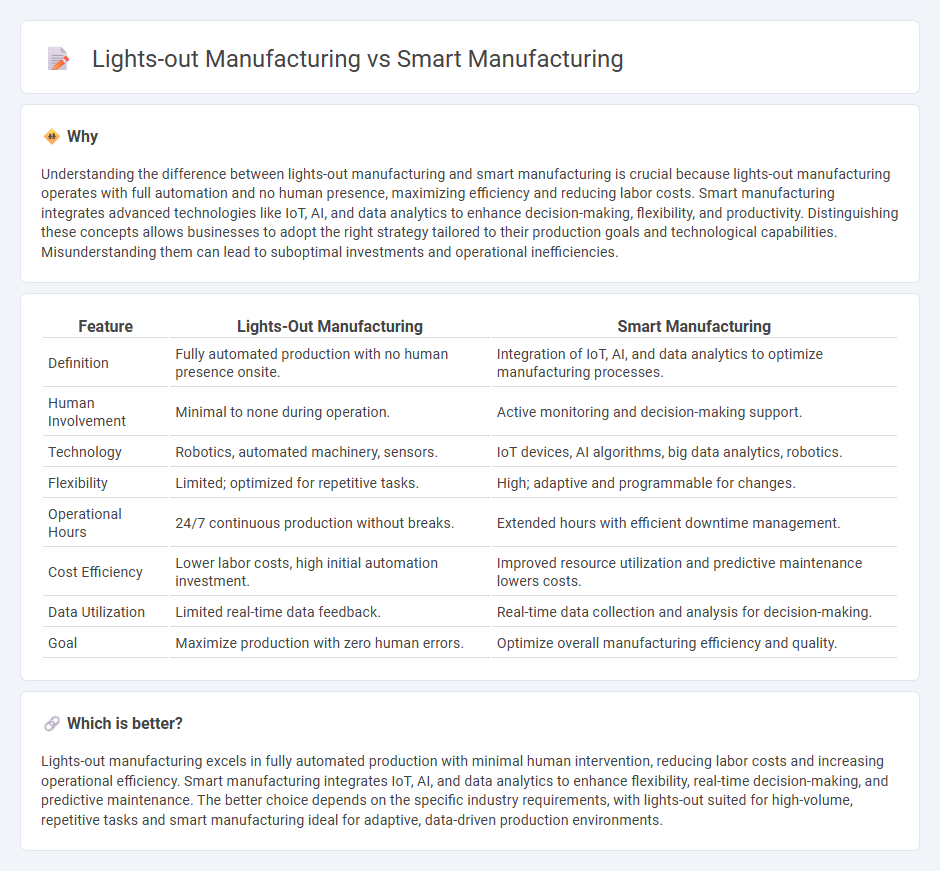

Understanding the difference between lights-out manufacturing and smart manufacturing is crucial because lights-out manufacturing operates with full automation and no human presence, maximizing efficiency and reducing labor costs. Smart manufacturing integrates advanced technologies like IoT, AI, and data analytics to enhance decision-making, flexibility, and productivity. Distinguishing these concepts allows businesses to adopt the right strategy tailored to their production goals and technological capabilities. Misunderstanding them can lead to suboptimal investments and operational inefficiencies.

Comparison Table

| Feature | Lights-Out Manufacturing | Smart Manufacturing |

|---|---|---|

| Definition | Fully automated production with no human presence onsite. | Integration of IoT, AI, and data analytics to optimize manufacturing processes. |

| Human Involvement | Minimal to none during operation. | Active monitoring and decision-making support. |

| Technology | Robotics, automated machinery, sensors. | IoT devices, AI algorithms, big data analytics, robotics. |

| Flexibility | Limited; optimized for repetitive tasks. | High; adaptive and programmable for changes. |

| Operational Hours | 24/7 continuous production without breaks. | Extended hours with efficient downtime management. |

| Cost Efficiency | Lower labor costs, high initial automation investment. | Improved resource utilization and predictive maintenance lowers costs. |

| Data Utilization | Limited real-time data feedback. | Real-time data collection and analysis for decision-making. |

| Goal | Maximize production with zero human errors. | Optimize overall manufacturing efficiency and quality. |

Which is better?

Lights-out manufacturing excels in fully automated production with minimal human intervention, reducing labor costs and increasing operational efficiency. Smart manufacturing integrates IoT, AI, and data analytics to enhance flexibility, real-time decision-making, and predictive maintenance. The better choice depends on the specific industry requirements, with lights-out suited for high-volume, repetitive tasks and smart manufacturing ideal for adaptive, data-driven production environments.

Connection

Lights-out manufacturing leverages automation and robotics to operate factories without human intervention, significantly enhancing efficiency and reducing labor costs. Smart manufacturing integrates advanced data analytics, IoT sensors, and AI to optimize production processes, enabling real-time monitoring and predictive maintenance. The connection lies in smart manufacturing technologies enabling effective implementation and management of lights-out manufacturing by providing the intelligence and data insights necessary for fully automated operations.

Key Terms

Automation

Smart manufacturing integrates cyber-physical systems, IoT, and AI to enhance production flexibility and efficiency through real-time data analytics and adaptive processes. Lights-out manufacturing emphasizes fully autonomous operations without human presence, relying heavily on robotics, automated machinery, and advanced control systems for uninterrupted production. Explore the transformative impact of automation in these manufacturing paradigms to drive innovation and operational excellence.

Data Analytics

Smart manufacturing leverages advanced data analytics to optimize production processes, improve quality control, and reduce operational costs through real-time insights and predictive maintenance. Lights-out manufacturing advances this concept by automating factories to operate without human intervention, relying heavily on data analytics for autonomous decision-making and fault detection. Explore the transformative impact of data analytics in these manufacturing paradigms to understand their role in shaping Industry 4.0.

Human Intervention

Smart manufacturing integrates advanced technologies such as IoT, AI, and robotics to enhance production efficiency while still relying on human oversight and intervention for decision-making and quality control. Lights-out manufacturing operates with minimal or no human presence by fully automating production lines, aiming for continuous, unattended operation. Explore the differences in human roles and automation levels to understand how each approach impacts manufacturing dynamics.

Source and External Links

What Is Smart Manufacturing? | Oracle - Smart manufacturing involves modern data science and artificial intelligence to enhance manufacturing processes, improving efficiency and sustainability.

What Is Smart Manufacturing? - CESMII - Smart manufacturing integrates business, physical, and digital processes to achieve efficiency, scalability, and sustainability through real-time data and automation.

Smart Manufacturing | Rockwell Automation - Smart manufacturing provides insights to optimize productivity, quality, risk management, and sustainability by leveraging advanced technologies and real-time data.

dowidth.com

dowidth.com