Collaborative robots (cobots) integrate seamlessly with human workers on manufacturing floors, enhancing precision and efficiency without extensive reprogramming. Flexible manufacturing systems (FMS) utilize automated machines and material handling to adapt quickly to varying product demands and production schedules. Explore how cobots and FMS transform manufacturing agility and productivity in modern industries.

Why it is important

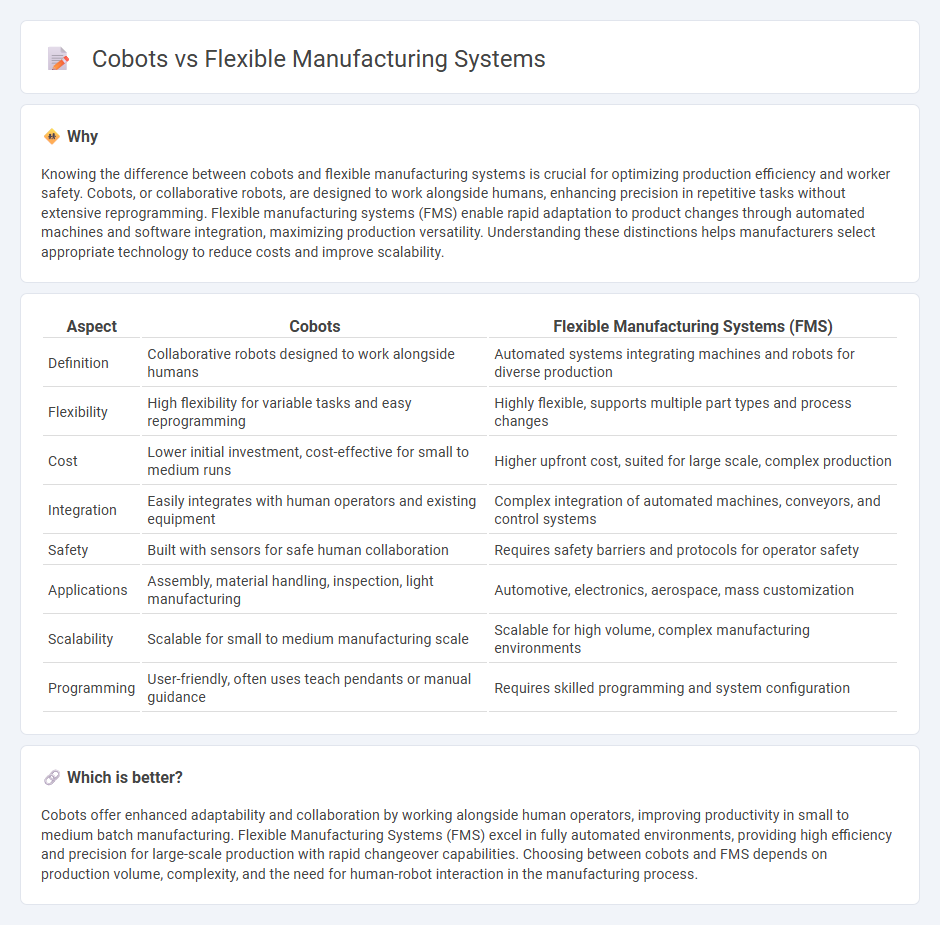

Knowing the difference between cobots and flexible manufacturing systems is crucial for optimizing production efficiency and worker safety. Cobots, or collaborative robots, are designed to work alongside humans, enhancing precision in repetitive tasks without extensive reprogramming. Flexible manufacturing systems (FMS) enable rapid adaptation to product changes through automated machines and software integration, maximizing production versatility. Understanding these distinctions helps manufacturers select appropriate technology to reduce costs and improve scalability.

Comparison Table

| Aspect | Cobots | Flexible Manufacturing Systems (FMS) |

|---|---|---|

| Definition | Collaborative robots designed to work alongside humans | Automated systems integrating machines and robots for diverse production |

| Flexibility | High flexibility for variable tasks and easy reprogramming | Highly flexible, supports multiple part types and process changes |

| Cost | Lower initial investment, cost-effective for small to medium runs | Higher upfront cost, suited for large scale, complex production |

| Integration | Easily integrates with human operators and existing equipment | Complex integration of automated machines, conveyors, and control systems |

| Safety | Built with sensors for safe human collaboration | Requires safety barriers and protocols for operator safety |

| Applications | Assembly, material handling, inspection, light manufacturing | Automotive, electronics, aerospace, mass customization |

| Scalability | Scalable for small to medium manufacturing scale | Scalable for high volume, complex manufacturing environments |

| Programming | User-friendly, often uses teach pendants or manual guidance | Requires skilled programming and system configuration |

Which is better?

Cobots offer enhanced adaptability and collaboration by working alongside human operators, improving productivity in small to medium batch manufacturing. Flexible Manufacturing Systems (FMS) excel in fully automated environments, providing high efficiency and precision for large-scale production with rapid changeover capabilities. Choosing between cobots and FMS depends on production volume, complexity, and the need for human-robot interaction in the manufacturing process.

Connection

Cobots (collaborative robots) enhance flexible manufacturing systems by enabling adaptable, precise automation in shared human-robot workspaces. These robots improve production efficiency by seamlessly integrating with various tasks without extensive reprogramming or physical reconfiguration. The synergy between cobots and flexible manufacturing systems drives increased responsiveness and customization in modern industrial processes.

Key Terms

Automation

Flexible manufacturing systems (FMS) integrate automated machines and robots to optimize production efficiency, reduce cycle times, and adapt rapidly to changing product designs. Cobots, or collaborative robots, enhance automation by working safely alongside human operators, improving precision and flexibility on the factory floor without extensive safety barriers. Explore how combining FMS with cobots revolutionizes automation to boost productivity and operational agility.

Adaptability

Flexible manufacturing systems (FMS) excel in adaptability through automated machinery configured to handle diverse production tasks with minimal changeover time, enhancing efficiency in mass customization. Cobots offer direct human-robot collaboration, allowing for real-time adjustments and easy reprogramming, making them highly versatile in dynamic production environments. Explore how integrating FMS and cobots can maximize manufacturing adaptability and operational responsiveness.

Human-robot collaboration

Flexible manufacturing systems integrate automated machinery and human operators to optimize production adaptability and efficiency, while cobots (collaborative robots) are designed specifically to work safely alongside humans in shared workspaces to enhance productivity and flexibility. Cobots offer intuitive programming and real-time interaction, improving human-robot collaboration by augmenting human skills without replacing the workforce. Explore the latest advancements in human-robot collaboration to understand how these technologies reshape modern manufacturing environments.

Source and External Links

Flexible manufacturing system - Wikipedia - A flexible manufacturing system (FMS) is a production setup that allows for adaptability in response to changes, offering flexibility in routing and machine operations.

Flexible Manufacturing Systems (FMS) - Autodesk - Flexible manufacturing systems are computer-controlled setups designed to adapt to changes in product details, leveraging routing and machine flexibility for efficient production.

How Flexible Manufacturing System (FMS) is Changing Production - Flexible manufacturing systems integrate automation and computer control to manage production efficiently, allowing real-time adjustments and maintaining quality standards.

dowidth.com

dowidth.com