Hyperautomation leverages advanced technologies like AI, machine learning, and robotic process automation to streamline manufacturing workflows and enhance operational efficiency by automating complex tasks. Enterprise Resource Planning (ERP) systems integrate core manufacturing processes such as inventory management, production scheduling, and supply chain coordination into a unified platform for real-time data visibility. Explore the impact of hyperautomation and ERP in transforming manufacturing operations to unlock next-level productivity and innovation.

Why it is important

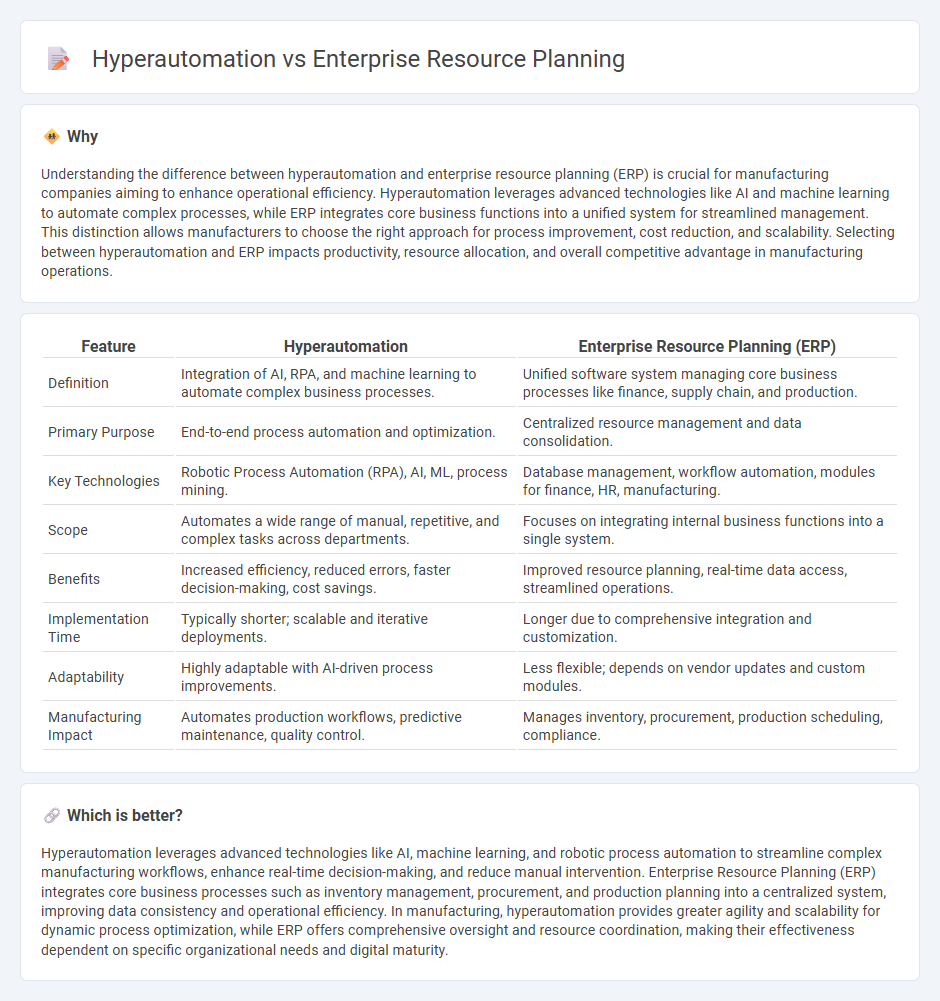

Understanding the difference between hyperautomation and enterprise resource planning (ERP) is crucial for manufacturing companies aiming to enhance operational efficiency. Hyperautomation leverages advanced technologies like AI and machine learning to automate complex processes, while ERP integrates core business functions into a unified system for streamlined management. This distinction allows manufacturers to choose the right approach for process improvement, cost reduction, and scalability. Selecting between hyperautomation and ERP impacts productivity, resource allocation, and overall competitive advantage in manufacturing operations.

Comparison Table

| Feature | Hyperautomation | Enterprise Resource Planning (ERP) |

|---|---|---|

| Definition | Integration of AI, RPA, and machine learning to automate complex business processes. | Unified software system managing core business processes like finance, supply chain, and production. |

| Primary Purpose | End-to-end process automation and optimization. | Centralized resource management and data consolidation. |

| Key Technologies | Robotic Process Automation (RPA), AI, ML, process mining. | Database management, workflow automation, modules for finance, HR, manufacturing. |

| Scope | Automates a wide range of manual, repetitive, and complex tasks across departments. | Focuses on integrating internal business functions into a single system. |

| Benefits | Increased efficiency, reduced errors, faster decision-making, cost savings. | Improved resource planning, real-time data access, streamlined operations. |

| Implementation Time | Typically shorter; scalable and iterative deployments. | Longer due to comprehensive integration and customization. |

| Adaptability | Highly adaptable with AI-driven process improvements. | Less flexible; depends on vendor updates and custom modules. |

| Manufacturing Impact | Automates production workflows, predictive maintenance, quality control. | Manages inventory, procurement, production scheduling, compliance. |

Which is better?

Hyperautomation leverages advanced technologies like AI, machine learning, and robotic process automation to streamline complex manufacturing workflows, enhance real-time decision-making, and reduce manual intervention. Enterprise Resource Planning (ERP) integrates core business processes such as inventory management, procurement, and production planning into a centralized system, improving data consistency and operational efficiency. In manufacturing, hyperautomation provides greater agility and scalability for dynamic process optimization, while ERP offers comprehensive oversight and resource coordination, making their effectiveness dependent on specific organizational needs and digital maturity.

Connection

Hyperautomation enhances manufacturing efficiency by integrating with enterprise resource planning (ERP) systems to automate complex workflows and data management. ERP platforms centralize production data, while hyperautomation employs AI and robotic process automation (RPA) to optimize supply chain, inventory control, and quality assurance processes. This synergy reduces operational costs, accelerates decision-making, and improves overall manufacturing productivity.

Key Terms

**Enterprise Resource Planning (ERP):**

Enterprise Resource Planning (ERP) integrates core business processes such as finance, supply chain, and human resources into a unified system, streamlining operations and improving data visibility. ERP systems enhance organizational efficiency by automating routine tasks, enabling real-time data analysis, and supporting informed decision-making. Explore how ERP solutions can transform your business by delivering seamless operational control and innovation.

Integration

Enterprise Resource Planning (ERP) systems centralize business processes by integrating core functions like finance, supply chain, and HR into a unified platform, streamlining data flow and enhancing operational efficiency. Hyperautomation extends integration by leveraging AI, machine learning, and robotic process automation (RPA) to automate complex workflows across multiple systems beyond traditional ERP boundaries. Explore how combining ERP with hyperautomation can drive seamless integration and transformative business growth.

Modules

Enterprise Resource Planning (ERP) systems encompass integrated modules such as finance, human resources, supply chain management, and customer relationship management to centralize business processes. Hyperautomation leverages advanced technologies like AI, machine learning, and robotic process automation to enhance or automate workflows across multiple ERP modules, driving efficiency and scalability. Explore detailed insights on how ERP modules intertwine with hyperautomation for transformative business operations.

Source and External Links

Enterprise resource planning - Wikipedia - ERP is integrated management of main business processes via software, providing a unified view of resources and operations, supporting both local and cloud-based systems to enhance organizational efficiency in real time.

What is Enterprise Resource Planning (ERP)? - IBM - ERP is a business management software system that automates and integrates an organization's functions and workflows across finance, HR, manufacturing, supply chain, and more, using connected modules sharing a common database.

What Is ERP? - Oracle - ERP is a comprehensive software system that manages day-to-day business activities like accounting, procurement, project management, and supply chain operations, ensuring data integrity with a single source of truth and supporting businesses of all sizes.

dowidth.com

dowidth.com