Additive manufacturing builds objects layer-by-layer using digital models, enabling complex geometries and material efficiency unmatched by traditional forging methods. Forging involves shaping metal through compressive forces at elevated temperatures, producing components with superior mechanical properties and structural integrity. Explore the advantages and applications of both techniques to determine the ideal manufacturing process for your needs.

Why it is important

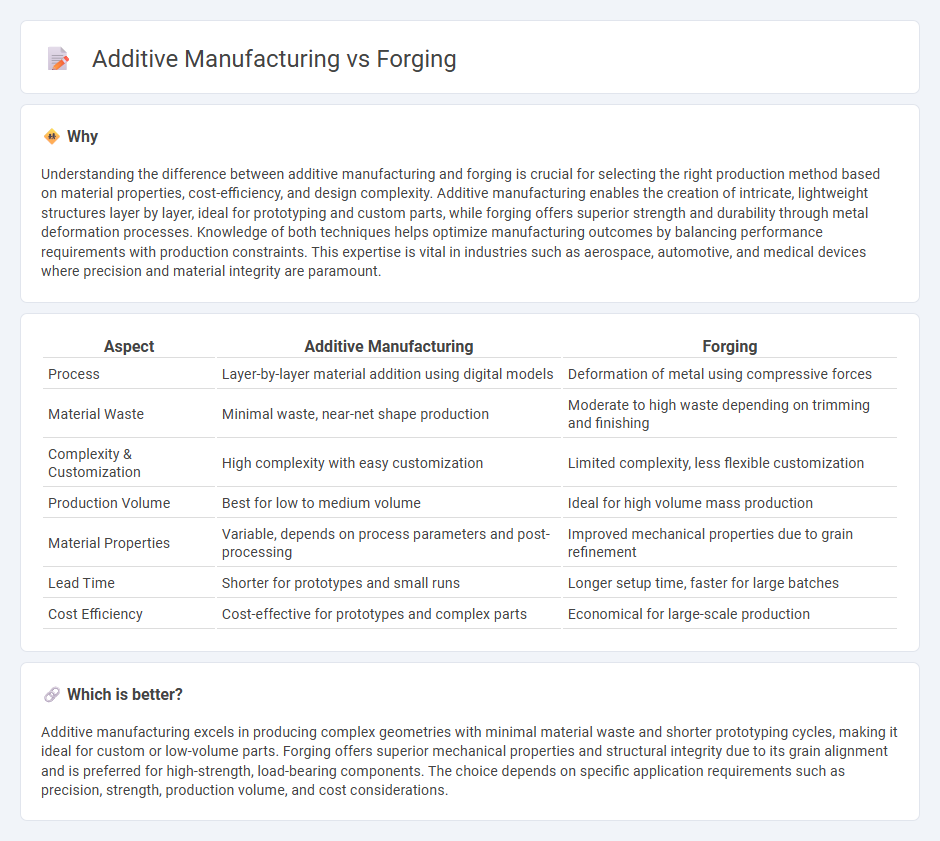

Understanding the difference between additive manufacturing and forging is crucial for selecting the right production method based on material properties, cost-efficiency, and design complexity. Additive manufacturing enables the creation of intricate, lightweight structures layer by layer, ideal for prototyping and custom parts, while forging offers superior strength and durability through metal deformation processes. Knowledge of both techniques helps optimize manufacturing outcomes by balancing performance requirements with production constraints. This expertise is vital in industries such as aerospace, automotive, and medical devices where precision and material integrity are paramount.

Comparison Table

| Aspect | Additive Manufacturing | Forging |

|---|---|---|

| Process | Layer-by-layer material addition using digital models | Deformation of metal using compressive forces |

| Material Waste | Minimal waste, near-net shape production | Moderate to high waste depending on trimming and finishing |

| Complexity & Customization | High complexity with easy customization | Limited complexity, less flexible customization |

| Production Volume | Best for low to medium volume | Ideal for high volume mass production |

| Material Properties | Variable, depends on process parameters and post-processing | Improved mechanical properties due to grain refinement |

| Lead Time | Shorter for prototypes and small runs | Longer setup time, faster for large batches |

| Cost Efficiency | Cost-effective for prototypes and complex parts | Economical for large-scale production |

Which is better?

Additive manufacturing excels in producing complex geometries with minimal material waste and shorter prototyping cycles, making it ideal for custom or low-volume parts. Forging offers superior mechanical properties and structural integrity due to its grain alignment and is preferred for high-strength, load-bearing components. The choice depends on specific application requirements such as precision, strength, production volume, and cost considerations.

Connection

Additive manufacturing and forging are connected through their complementary roles in producing complex, high-strength components by combining precision layering with material densification. Additive manufacturing enables the creation of intricate geometries and near-net-shape parts, which can then be enhanced through forging processes to improve mechanical properties and structural integrity. This hybrid approach optimizes material usage, reduces waste, and achieves superior performance in aerospace, automotive, and industrial applications.

Key Terms

Deformation

Forging involves plastic deformation of metals using compressive forces to shape workpieces, enhancing grain flow and mechanical properties through controlled deformation. Additive manufacturing builds components layer by layer without bulk deformation, resulting in distinct microstructures and mechanical behavior compared to forged parts. Explore further to understand how deformation impacts material performance in these manufacturing methods.

Layer-by-layer

Forging shapes metal through compressive forces to enhance grain structure and mechanical properties, whereas additive manufacturing builds parts layer-by-layer by depositing material precisely, allowing for complex geometries and reduced waste. The layer-by-layer approach in additive manufacturing enables customization and rapid prototyping that traditional forging cannot achieve. Explore the benefits and applications of both processes to determine the best manufacturing method for your project.

Tooling

Forging produces high-strength tooling components by compressing metal under extreme pressure, resulting in superior grain structure and durability, essential for high-performance applications. Additive manufacturing enables intricate tooling designs with complex geometries and internal features that are challenging to achieve through forging, improving customization and rapid prototyping. Explore the advantages and applications of both methods in tooling to optimize manufacturing efficiency and product quality.

Source and External Links

Forging - Forging is a manufacturing process that involves shaping metal using localized compressive forces, often classified by temperature as cold, warm, or hot forging.

Smithy Secrets: An Intro to Forging Methods - This article introduces the basics of forging, including its methods, materials, and benefits in producing high-strength parts with minimal waste.

Defined Forging - This guide defines forging as a process of heating and deforming metal to create customized shapes, emphasizing its ability to produce strong components for various industries.

dowidth.com

dowidth.com