Digital twinning creates a virtual replica of physical assets to simulate performance and optimize operations, enhancing precision in manufacturing processes. Predictive maintenance uses real-time data and advanced analytics to forecast equipment failures, minimizing downtime and reducing repair costs. Explore how these technologies transform manufacturing efficiency and reliability.

Why it is important

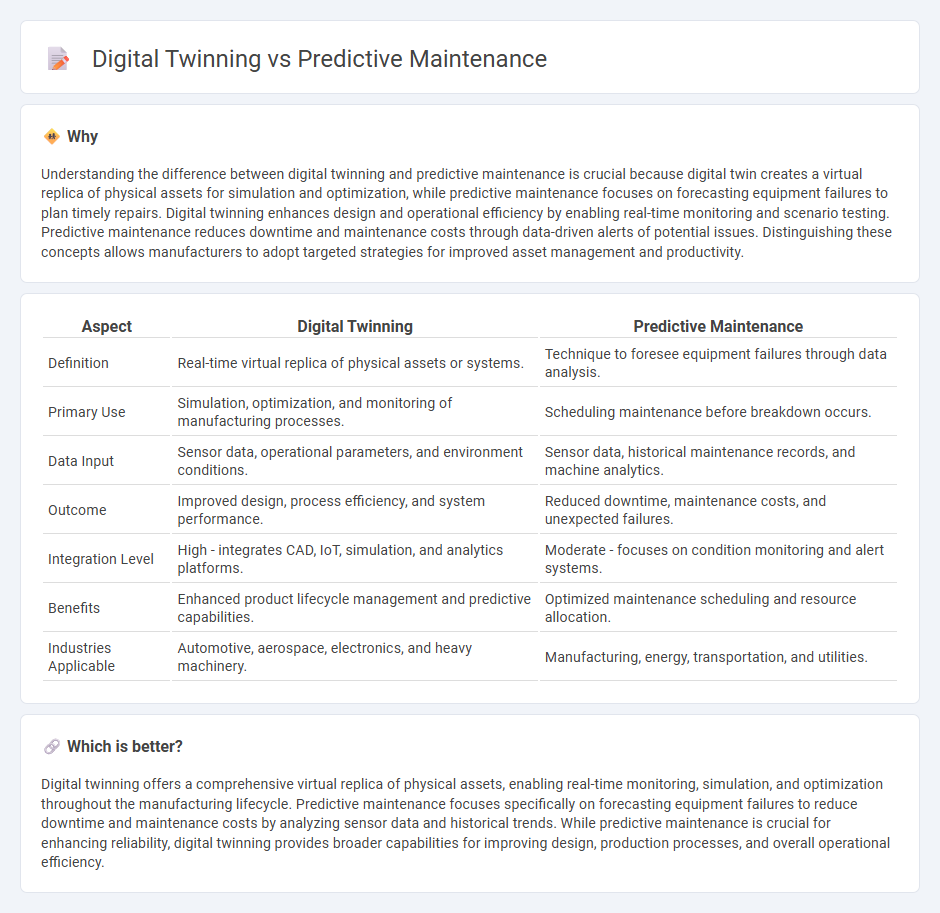

Understanding the difference between digital twinning and predictive maintenance is crucial because digital twin creates a virtual replica of physical assets for simulation and optimization, while predictive maintenance focuses on forecasting equipment failures to plan timely repairs. Digital twinning enhances design and operational efficiency by enabling real-time monitoring and scenario testing. Predictive maintenance reduces downtime and maintenance costs through data-driven alerts of potential issues. Distinguishing these concepts allows manufacturers to adopt targeted strategies for improved asset management and productivity.

Comparison Table

| Aspect | Digital Twinning | Predictive Maintenance |

|---|---|---|

| Definition | Real-time virtual replica of physical assets or systems. | Technique to foresee equipment failures through data analysis. |

| Primary Use | Simulation, optimization, and monitoring of manufacturing processes. | Scheduling maintenance before breakdown occurs. |

| Data Input | Sensor data, operational parameters, and environment conditions. | Sensor data, historical maintenance records, and machine analytics. |

| Outcome | Improved design, process efficiency, and system performance. | Reduced downtime, maintenance costs, and unexpected failures. |

| Integration Level | High - integrates CAD, IoT, simulation, and analytics platforms. | Moderate - focuses on condition monitoring and alert systems. |

| Benefits | Enhanced product lifecycle management and predictive capabilities. | Optimized maintenance scheduling and resource allocation. |

| Industries Applicable | Automotive, aerospace, electronics, and heavy machinery. | Manufacturing, energy, transportation, and utilities. |

Which is better?

Digital twinning offers a comprehensive virtual replica of physical assets, enabling real-time monitoring, simulation, and optimization throughout the manufacturing lifecycle. Predictive maintenance focuses specifically on forecasting equipment failures to reduce downtime and maintenance costs by analyzing sensor data and historical trends. While predictive maintenance is crucial for enhancing reliability, digital twinning provides broader capabilities for improving design, production processes, and overall operational efficiency.

Connection

Digital twinning integrates real-time sensor data to create virtual replicas of manufacturing equipment, enabling continuous monitoring of system performance and health. Predictive maintenance leverages these digital twins by analyzing simulated scenarios and historical data to forecast potential failures and optimize maintenance schedules. This synergy reduces downtime, enhances operational efficiency, and extends the lifespan of manufacturing assets.

Key Terms

Condition Monitoring

Predictive maintenance leverages real-time sensor data and machine learning algorithms to anticipate equipment failures, reducing downtime and maintenance costs. Digital twinning creates a virtual replica of physical assets, enabling comprehensive condition monitoring through simulation and analysis of performance under varying conditions. Explore how integrating these technologies enhances asset management and operational efficiency.

Real-time Simulation

Predictive maintenance leverages real-time sensor data and machine learning algorithms to forecast equipment failures and optimize maintenance schedules, reducing downtime and operational costs. Digital twinning enhances this approach by creating a virtual replica of physical assets, enabling real-time simulation of multiple scenarios for proactive decision-making and performance optimization. Explore how integrating predictive maintenance with digital twins revolutionizes asset management and operational efficiency.

Failure Prediction

Predictive maintenance leverages real-time sensor data and machine learning algorithms to anticipate equipment failures before they occur, minimizing downtime and reducing repair costs. Digital twinning creates a virtual replica of physical assets, enabling simulation of various scenarios to predict potential failures with high accuracy through continuous monitoring and data integration. Explore how these advanced technologies synergize to enhance failure prediction and optimize operational efficiency.

Source and External Links

What is Predictive Maintenance? - Predictive maintenance predicts the potential future state of equipment using sensor data and machine learning to schedule maintenance only when needed, reducing costs and downtime while optimizing equipment performance and lifespan.

Predictive maintenance - Predictive maintenance estimates when maintenance should be performed by monitoring the current condition of equipment, allowing better planning, fewer unplanned stops, and greater cost savings compared to routine preventive maintenance.

What is Predictive Maintenance? Benefits, Challenges & ... - Predictive maintenance uses real-time vehicle data and analytics to accurately predict failures, prioritize tasks, optimize inventory, extend asset life, and improve fleet safety by preventing breakdowns before they happen.

dowidth.com

dowidth.com