Lattice structure design optimizes material use by creating interconnected networks that deliver high strength-to-weight ratios and precise mechanical properties. Foam structure design focuses on energy absorption and thermal insulation, featuring random porous configurations that enhance impact resistance and reduce density. Explore further to understand the applications and benefits of each design in advanced manufacturing.

Why it is important

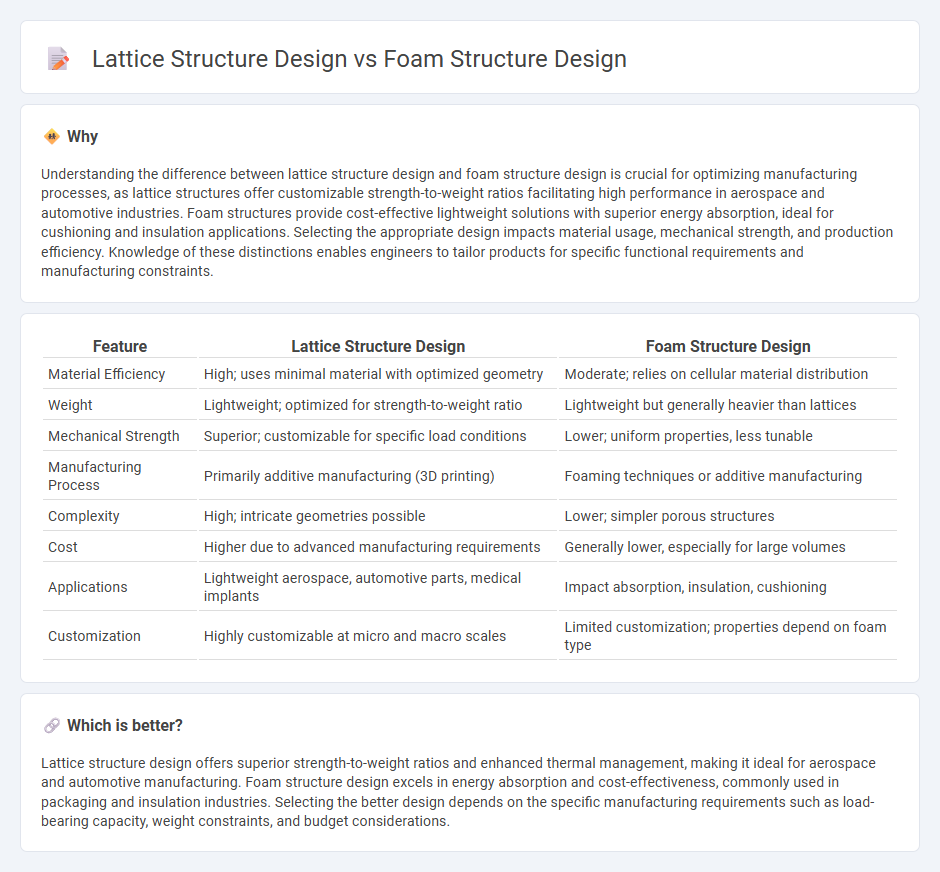

Understanding the difference between lattice structure design and foam structure design is crucial for optimizing manufacturing processes, as lattice structures offer customizable strength-to-weight ratios facilitating high performance in aerospace and automotive industries. Foam structures provide cost-effective lightweight solutions with superior energy absorption, ideal for cushioning and insulation applications. Selecting the appropriate design impacts material usage, mechanical strength, and production efficiency. Knowledge of these distinctions enables engineers to tailor products for specific functional requirements and manufacturing constraints.

Comparison Table

| Feature | Lattice Structure Design | Foam Structure Design |

|---|---|---|

| Material Efficiency | High; uses minimal material with optimized geometry | Moderate; relies on cellular material distribution |

| Weight | Lightweight; optimized for strength-to-weight ratio | Lightweight but generally heavier than lattices |

| Mechanical Strength | Superior; customizable for specific load conditions | Lower; uniform properties, less tunable |

| Manufacturing Process | Primarily additive manufacturing (3D printing) | Foaming techniques or additive manufacturing |

| Complexity | High; intricate geometries possible | Lower; simpler porous structures |

| Cost | Higher due to advanced manufacturing requirements | Generally lower, especially for large volumes |

| Applications | Lightweight aerospace, automotive parts, medical implants | Impact absorption, insulation, cushioning |

| Customization | Highly customizable at micro and macro scales | Limited customization; properties depend on foam type |

Which is better?

Lattice structure design offers superior strength-to-weight ratios and enhanced thermal management, making it ideal for aerospace and automotive manufacturing. Foam structure design excels in energy absorption and cost-effectiveness, commonly used in packaging and insulation industries. Selecting the better design depends on the specific manufacturing requirements such as load-bearing capacity, weight constraints, and budget considerations.

Connection

Lattice structure design and foam structure design are connected through their shared goal of optimizing material efficiency and mechanical performance in manufacturing. Both designs utilize interconnected voids or pores to reduce weight while maintaining strength, improving energy absorption and thermal properties. Advanced manufacturing techniques like additive manufacturing enable precise fabrication of these complex geometries, enhancing product performance in aerospace, automotive, and biomedical applications.

Key Terms

Porosity

Foam structure design features irregular, interconnected pores that enhance energy absorption and fluid flow, while lattice structure design uses periodic, geometric patterns offering precise control over porosity and mechanical properties. Porosity in foam designs typically ranges from 60% to 95%, optimizing impact resistance and thermal insulation, whereas lattice structures can be engineered with porosity levels tailored to specific load-bearing requirements, ranging from 30% to 80%. Explore detailed comparisons to determine the best porosity strategy for your application's performance needs.

Load Distribution

Foam structure design offers uniform load distribution through its interconnected porous network, enhancing energy absorption and impact resistance in applications like cushioning and lightweight components. Lattice structure design provides customizable load paths with precise control over stiffness and strength by varying cell geometry and orientation, widely used in aerospace and biomedical implants for optimized performance. Explore detailed comparisons and applications to understand which structural design best suits your engineering needs.

Manufacturing Complexity

Foam structure design features irregular, porous architectures that are simpler to produce using techniques like foaming or casting, resulting in lower manufacturing complexity. Lattice structure design involves precise, repeatable geometric patterns often created via advanced additive manufacturing methods, which demand higher precision and longer production times. Explore the detailed comparison of manufacturing processes and complexity for foam and lattice structures to optimize your design strategy.

Source and External Links

GE Engineering Structural Foam DESIGN & PROCESSING GUIDE - Structural foam design features a foam core between two dense skins created by gas expansion in molten resin, offering high strength, rigidity, reduced part weight, and corrosion resistance, with typical wall thicknesses of 0.15-0.5 inches and benefits including improved heat insulation and acoustics.

The Basics Of Structural Foam Molding - Structural foam molding requires thicker part walls (over 1/4 inch) for proper chemical foaming, and finished surfaces are rough, often needing sanding and multi-step painting for aesthetic improvements.

Design Guide - Structural Foam Molding - Structural foam molding enables manufacture of very large, complex parts with lower residual stress, providing benefits such as large part sizes, smooth outer surfaces, lower weight, high strength-to-weight ratio, high impact resistance, dimensional stability, and use of aluminum molds for faster cycles.

dowidth.com

dowidth.com