Digital twinning creates precise virtual replicas of physical manufacturing assets, enabling real-time simulation and predictive maintenance to optimize production efficiency. Industrial IoT (IIoT) connects machinery and devices through sensors and networks, facilitating extensive data collection, remote monitoring, and automation across manufacturing processes. Explore the distinct advantages and applications of digital twinning versus IIoT to enhance your manufacturing strategy.

Why it is important

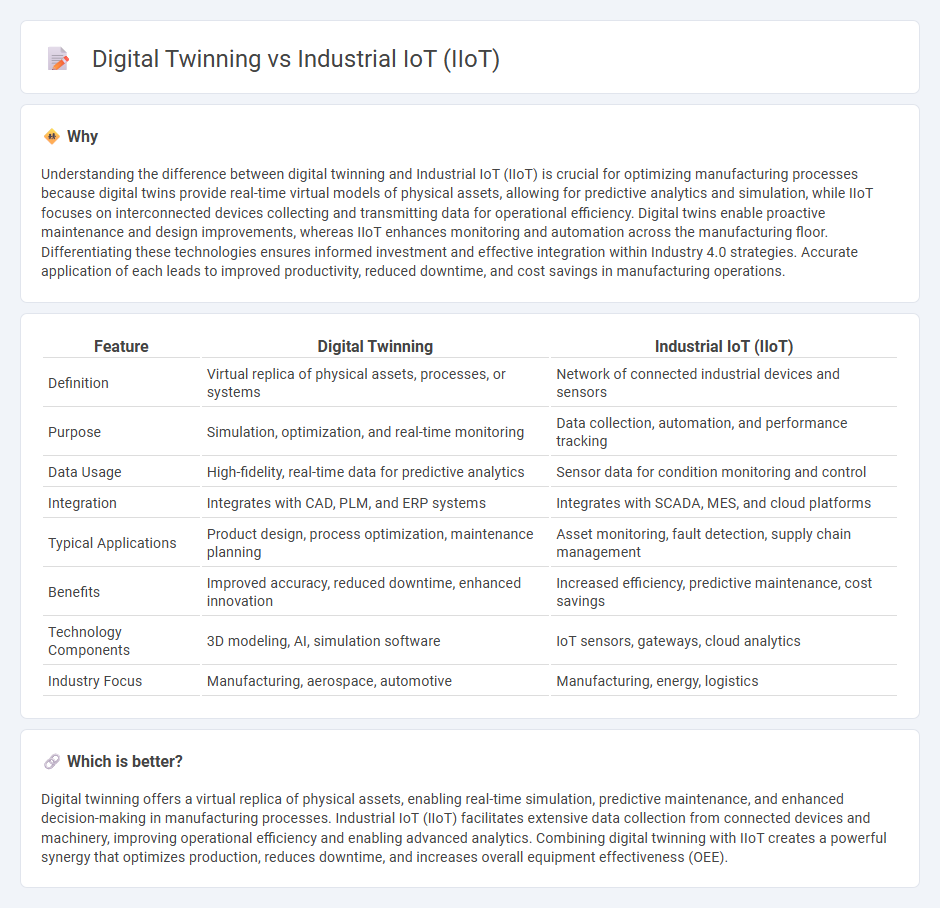

Understanding the difference between digital twinning and Industrial IoT (IIoT) is crucial for optimizing manufacturing processes because digital twins provide real-time virtual models of physical assets, allowing for predictive analytics and simulation, while IIoT focuses on interconnected devices collecting and transmitting data for operational efficiency. Digital twins enable proactive maintenance and design improvements, whereas IIoT enhances monitoring and automation across the manufacturing floor. Differentiating these technologies ensures informed investment and effective integration within Industry 4.0 strategies. Accurate application of each leads to improved productivity, reduced downtime, and cost savings in manufacturing operations.

Comparison Table

| Feature | Digital Twinning | Industrial IoT (IIoT) |

|---|---|---|

| Definition | Virtual replica of physical assets, processes, or systems | Network of connected industrial devices and sensors |

| Purpose | Simulation, optimization, and real-time monitoring | Data collection, automation, and performance tracking |

| Data Usage | High-fidelity, real-time data for predictive analytics | Sensor data for condition monitoring and control |

| Integration | Integrates with CAD, PLM, and ERP systems | Integrates with SCADA, MES, and cloud platforms |

| Typical Applications | Product design, process optimization, maintenance planning | Asset monitoring, fault detection, supply chain management |

| Benefits | Improved accuracy, reduced downtime, enhanced innovation | Increased efficiency, predictive maintenance, cost savings |

| Technology Components | 3D modeling, AI, simulation software | IoT sensors, gateways, cloud analytics |

| Industry Focus | Manufacturing, aerospace, automotive | Manufacturing, energy, logistics |

Which is better?

Digital twinning offers a virtual replica of physical assets, enabling real-time simulation, predictive maintenance, and enhanced decision-making in manufacturing processes. Industrial IoT (IIoT) facilitates extensive data collection from connected devices and machinery, improving operational efficiency and enabling advanced analytics. Combining digital twinning with IIoT creates a powerful synergy that optimizes production, reduces downtime, and increases overall equipment effectiveness (OEE).

Connection

Digital twinning leverages Industrial IoT (IIoT) by integrating real-time sensor data from connected manufacturing equipment to create accurate virtual models of physical assets. This connection enables predictive maintenance, process optimization, and enhanced decision-making through continuous monitoring and simulation. The synergy between digital twins and IIoT accelerates operational efficiency and reduces downtime in smart manufacturing environments.

Key Terms

Sensors & Connectivity

Industrial IoT integrates advanced sensors and connectivity technologies to collect real-time data from machinery, enhancing operational efficiency and predictive maintenance in manufacturing environments. Digital twinning creates virtual replicas of physical assets, leveraging sensor data to simulate performance, optimize processes, and detect anomalies before they occur. Explore how these technologies converge to revolutionize industrial operations and create smarter ecosystems.

Real-time Data Analytics

Industrial IoT (IIoT) enables real-time data collection from interconnected sensors and devices across manufacturing and industrial processes, driving operational efficiency and predictive maintenance. Digital twinning utilizes this real-time data to create dynamic virtual replicas of physical assets, allowing for advanced simulations and performance optimizations in a risk-free environment. Explore how integrating IIoT with digital twinning transforms real-time data analytics for smarter industrial decision-making.

Virtual Representation

Industrial IoT (IIoT) enables real-time data collection from interconnected devices, facilitating improved operational efficiency and predictive maintenance. Digital twinning creates a virtual representation of physical assets, simulating their behavior and performance for enhanced analysis and decision-making. Explore how integrating IIoT with digital twins can revolutionize industrial processes and asset management.

Source and External Links

Industrial IoT | Digital Transformation - AWS - Industrial IoT (IIoT) integrates machines, cloud computing, analytics, and people to enhance industrial process performance and productivity by connecting billions of devices for use cases like predictive quality, maintenance analytics, and process optimization across industries such as manufacturing and energy.

Industrial IoT: Understanding the Basics - IIoT is a network of connected smart devices tailored for industrial environments, using sophisticated sensors and analytics to enable real-time monitoring, predictive maintenance, and improved manufacturing and supply chain operations under rugged conditions.

What is IIoT (Industrial Internet of Things)? | Definition from TechTarget - IIoT employs smart sensors and actuators networked together to collect and analyze data in industrial settings, driving efficiencies such as predictive maintenance, quality control, energy management, and enhancing business decision-making with real-time analytics.

dowidth.com

dowidth.com