Zero defect manufacturing focuses on eliminating defects through rigorous quality control and continuous improvement processes, aiming for flawless production. Digital Twin technology leverages real-time data and virtual simulations to optimize manufacturing operations, predict maintenance needs, and enhance product quality. Explore how integrating these strategies can revolutionize manufacturing efficiency and precision.

Why it is important

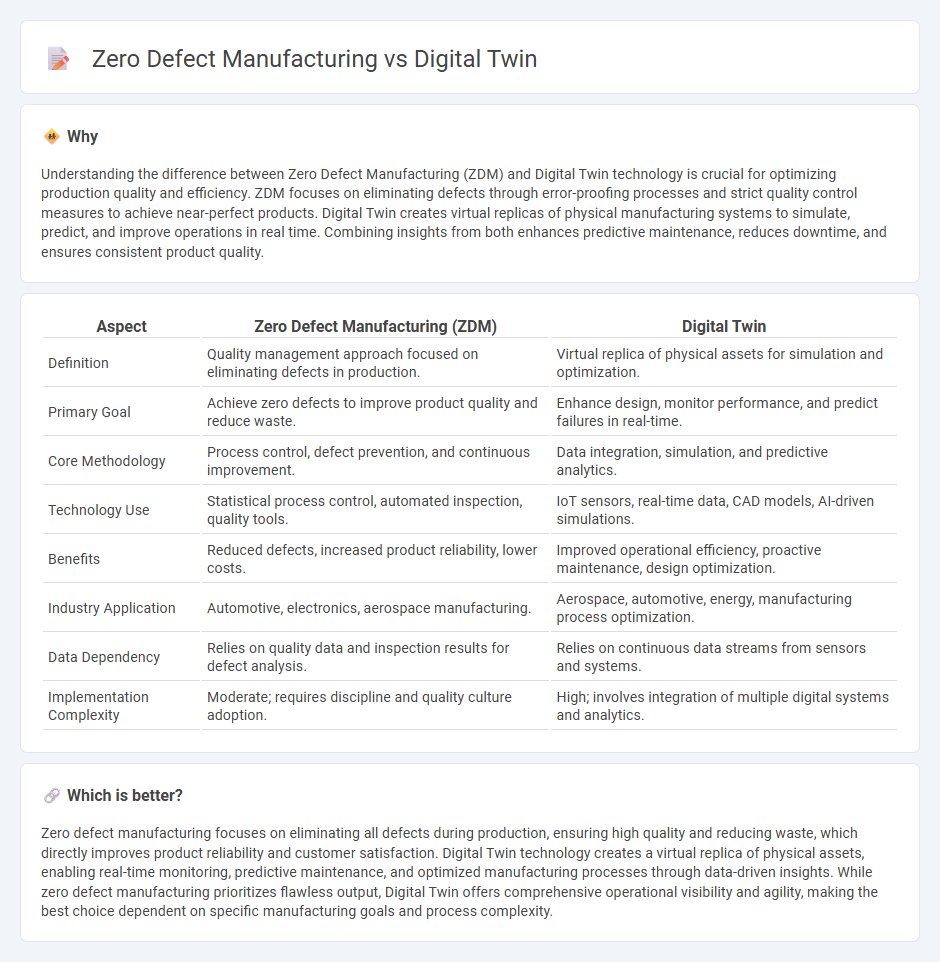

Understanding the difference between Zero Defect Manufacturing (ZDM) and Digital Twin technology is crucial for optimizing production quality and efficiency. ZDM focuses on eliminating defects through error-proofing processes and strict quality control measures to achieve near-perfect products. Digital Twin creates virtual replicas of physical manufacturing systems to simulate, predict, and improve operations in real time. Combining insights from both enhances predictive maintenance, reduces downtime, and ensures consistent product quality.

Comparison Table

| Aspect | Zero Defect Manufacturing (ZDM) | Digital Twin |

|---|---|---|

| Definition | Quality management approach focused on eliminating defects in production. | Virtual replica of physical assets for simulation and optimization. |

| Primary Goal | Achieve zero defects to improve product quality and reduce waste. | Enhance design, monitor performance, and predict failures in real-time. |

| Core Methodology | Process control, defect prevention, and continuous improvement. | Data integration, simulation, and predictive analytics. |

| Technology Use | Statistical process control, automated inspection, quality tools. | IoT sensors, real-time data, CAD models, AI-driven simulations. |

| Benefits | Reduced defects, increased product reliability, lower costs. | Improved operational efficiency, proactive maintenance, design optimization. |

| Industry Application | Automotive, electronics, aerospace manufacturing. | Aerospace, automotive, energy, manufacturing process optimization. |

| Data Dependency | Relies on quality data and inspection results for defect analysis. | Relies on continuous data streams from sensors and systems. |

| Implementation Complexity | Moderate; requires discipline and quality culture adoption. | High; involves integration of multiple digital systems and analytics. |

Which is better?

Zero defect manufacturing focuses on eliminating all defects during production, ensuring high quality and reducing waste, which directly improves product reliability and customer satisfaction. Digital Twin technology creates a virtual replica of physical assets, enabling real-time monitoring, predictive maintenance, and optimized manufacturing processes through data-driven insights. While zero defect manufacturing prioritizes flawless output, Digital Twin offers comprehensive operational visibility and agility, making the best choice dependent on specific manufacturing goals and process complexity.

Connection

Zero defect manufacturing relies on precise process control and real-time quality monitoring to eliminate defects, which is enhanced by the use of Digital Twin technology that creates virtual replicas of physical production systems. Digital Twins simulate manufacturing processes, enabling predictive analytics and early detection of potential defects before they occur on the actual production line. Integrating Digital Twins with zero defect strategies accelerates process optimization and ensures higher product quality and reduced downtime.

Key Terms

Virtual Simulation

Digital Twin technology enables real-time virtual simulation of manufacturing processes, capturing precise data to optimize production performance and predict system behaviors. Zero defect manufacturing focuses on minimizing errors by leveraging virtual simulations to detect potential faults before physical implementation, ensuring higher product quality and reduced waste. Explore how integrating Digital Twin and zero defect manufacturing strategies through advanced virtual simulation can revolutionize your production efficiency and quality control.

Real-time Data Analytics

Digital Twin technology creates virtual replicas of physical manufacturing systems, enabling real-time data analytics to monitor, simulate, and optimize production processes with high precision. Zero Defect Manufacturing leverages real-time data analytics to detect and eliminate defects during production, ensuring quality control and reducing waste. Explore how integrating Digital Twin and real-time analytics can drive zero defect initiatives for smarter, more efficient manufacturing.

Predictive Maintenance

Digital Twin technology enables real-time monitoring and simulation of manufacturing systems, enhancing predictive maintenance by forecasting equipment failures before they occur. Zero Defect Manufacturing focuses on minimizing defects through precise process control and quality management, leveraging data insights to prevent faults. Explore how integrating Digital Twin with Zero Defect Manufacturing transforms predictive maintenance and operational efficiency.

Source and External Links

Definition of a Digital Twin - A digital twin is an integrated data-driven virtual representation of real-world entities and processes with synchronized interaction, built on real-time and historical data to enable continuous improvement, decision-making, and prediction of future states.

Digital twin - Wikipedia - A digital twin is a digital model of a physical product, system, or process that updates in real time to simulate, test, monitor, and optimize its physical counterpart over its lifecycle.

What is Digital Twin and why is it important? | PTC - A digital twin is a virtual representation of a physical object, process, person, or place, combining digital definitions, operational data, and information models to enhance decision-making, reduce downtime, improve product design, and optimize operations.

dowidth.com

dowidth.com