Additive manufacturing builds objects layer by layer using materials such as plastics, metals, or composites, enabling complex geometries and reduced waste. Machining removes material from a solid block through cutting, drilling, and milling processes, offering precise tolerances and surface finishes. Explore the advantages and applications of both additive manufacturing and machining to determine the best fit for your production needs.

Why it is important

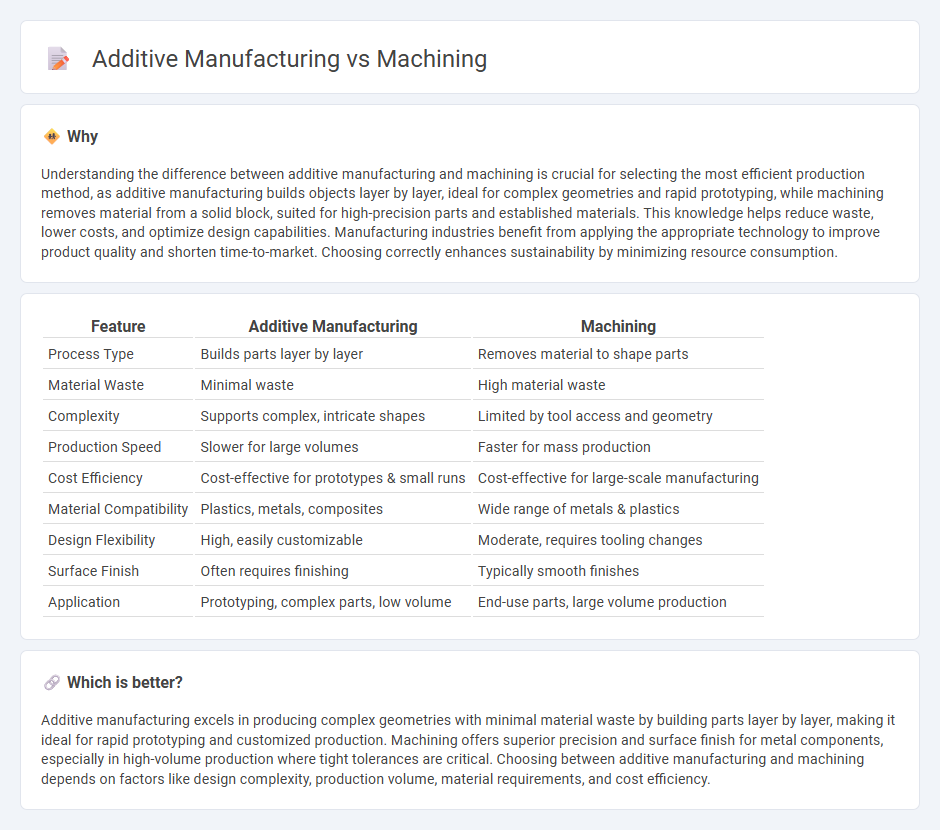

Understanding the difference between additive manufacturing and machining is crucial for selecting the most efficient production method, as additive manufacturing builds objects layer by layer, ideal for complex geometries and rapid prototyping, while machining removes material from a solid block, suited for high-precision parts and established materials. This knowledge helps reduce waste, lower costs, and optimize design capabilities. Manufacturing industries benefit from applying the appropriate technology to improve product quality and shorten time-to-market. Choosing correctly enhances sustainability by minimizing resource consumption.

Comparison Table

| Feature | Additive Manufacturing | Machining |

|---|---|---|

| Process Type | Builds parts layer by layer | Removes material to shape parts |

| Material Waste | Minimal waste | High material waste |

| Complexity | Supports complex, intricate shapes | Limited by tool access and geometry |

| Production Speed | Slower for large volumes | Faster for mass production |

| Cost Efficiency | Cost-effective for prototypes & small runs | Cost-effective for large-scale manufacturing |

| Material Compatibility | Plastics, metals, composites | Wide range of metals & plastics |

| Design Flexibility | High, easily customizable | Moderate, requires tooling changes |

| Surface Finish | Often requires finishing | Typically smooth finishes |

| Application | Prototyping, complex parts, low volume | End-use parts, large volume production |

Which is better?

Additive manufacturing excels in producing complex geometries with minimal material waste by building parts layer by layer, making it ideal for rapid prototyping and customized production. Machining offers superior precision and surface finish for metal components, especially in high-volume production where tight tolerances are critical. Choosing between additive manufacturing and machining depends on factors like design complexity, production volume, material requirements, and cost efficiency.

Connection

Additive manufacturing and machining are connected as complementary processes in modern manufacturing, where additive techniques build complex parts layer by layer and machining refines the surfaces and dimensions to precise specifications. Hybrid manufacturing systems integrate additive manufacturing for rapid prototyping and material deposition with CNC machining to achieve tight tolerances and smooth finishes. This synergy enhances production efficiency, reduces material waste, and enables the creation of intricate geometries unattainable by traditional subtractive methods alone.

Key Terms

Subtractive Process

Subtractive manufacturing involves the precise removal of material from a solid block using methods such as milling, turning, or drilling, resulting in highly accurate and smooth-finished parts. This process excels in producing components with tight tolerances and is widely used in industries like aerospace, automotive, and tooling. Explore more to understand how subtractive techniques compare with additive manufacturing in terms of efficiency, cost, and application suitability.

Layer-by-Layer Fabrication

Layer-by-layer fabrication in additive manufacturing builds parts by depositing material sequentially, enabling complex geometries and minimal waste compared to traditional subtractive machining, which removes material from a solid block. Additive methods such as 3D printing allow for rapid prototyping and customization, while machining excels in precision and surface finish for certain metals and hard materials. Explore detailed comparisons of layer-by-layer techniques and their industrial applications to understand the best fit for your manufacturing needs.

Material Removal

Machining involves subtractive manufacturing where material is selectively removed from a solid block using cutting tools like mills or lathes, enabling high precision and surface finish. Additive manufacturing builds objects layer-by-layer from raw materials such as powders or filaments, minimizing waste and allowing complex geometries unattainable by traditional machining. Explore the advantages and applications of both processes to determine the best fit for your production needs.

Source and External Links

Machining - Wikipedia - Machining is a subtractive manufacturing process where material, often metal, is removed from a larger piece to shape a desired part using machine tools.

What is Machining? Intro To Machine Shop Processes & Tools - Machining involves cutting, turning, milling, drilling, boring, and reaming to precisely shape materials into final parts or tools.

What is Machining: Definition, Types & Tools - 3ERP - As a manufacturing technique, machining shapes materials--including metals, plastics, and wood--into final products by controlled removal of excess material, typically using machine tools or CNC technology.

dowidth.com

dowidth.com