Adaptive machining employs real-time data and sensors to modify tool paths and cutting parameters, enhancing precision and reducing waste in production. Agile manufacturing focuses on flexible operations and quick changeovers to meet changing market demands efficiently. Explore how these advanced approaches transform manufacturing productivity and competitiveness.

Why it is important

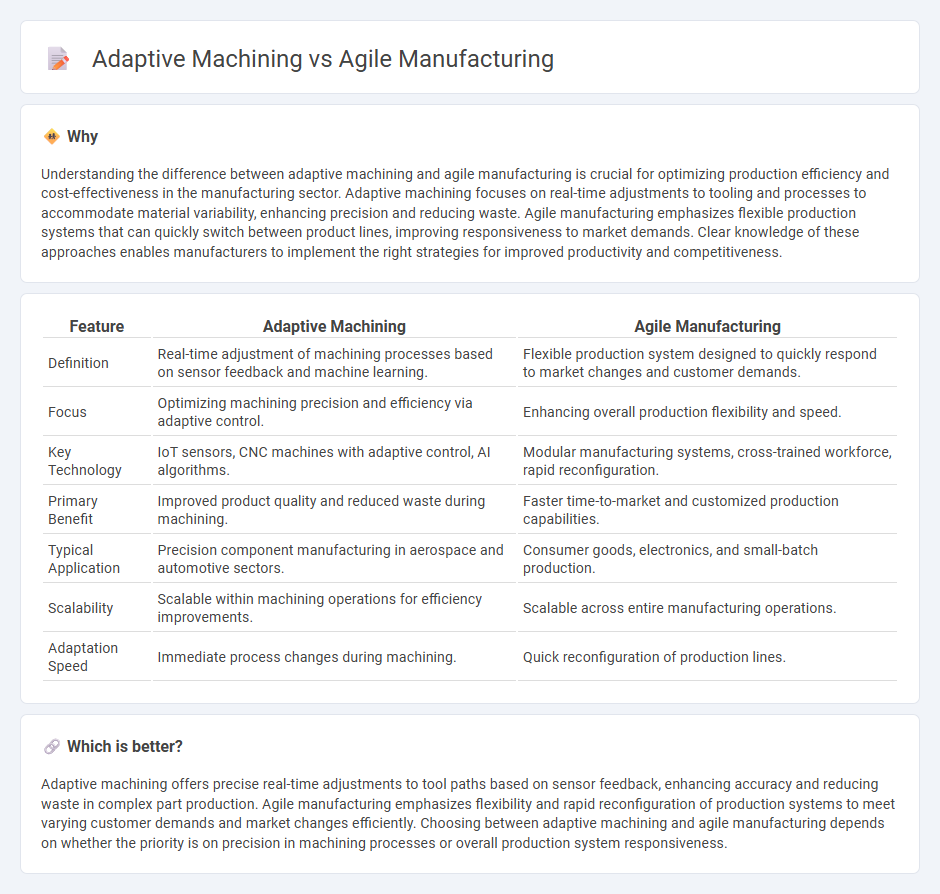

Understanding the difference between adaptive machining and agile manufacturing is crucial for optimizing production efficiency and cost-effectiveness in the manufacturing sector. Adaptive machining focuses on real-time adjustments to tooling and processes to accommodate material variability, enhancing precision and reducing waste. Agile manufacturing emphasizes flexible production systems that can quickly switch between product lines, improving responsiveness to market demands. Clear knowledge of these approaches enables manufacturers to implement the right strategies for improved productivity and competitiveness.

Comparison Table

| Feature | Adaptive Machining | Agile Manufacturing |

|---|---|---|

| Definition | Real-time adjustment of machining processes based on sensor feedback and machine learning. | Flexible production system designed to quickly respond to market changes and customer demands. |

| Focus | Optimizing machining precision and efficiency via adaptive control. | Enhancing overall production flexibility and speed. |

| Key Technology | IoT sensors, CNC machines with adaptive control, AI algorithms. | Modular manufacturing systems, cross-trained workforce, rapid reconfiguration. |

| Primary Benefit | Improved product quality and reduced waste during machining. | Faster time-to-market and customized production capabilities. |

| Typical Application | Precision component manufacturing in aerospace and automotive sectors. | Consumer goods, electronics, and small-batch production. |

| Scalability | Scalable within machining operations for efficiency improvements. | Scalable across entire manufacturing operations. |

| Adaptation Speed | Immediate process changes during machining. | Quick reconfiguration of production lines. |

Which is better?

Adaptive machining offers precise real-time adjustments to tool paths based on sensor feedback, enhancing accuracy and reducing waste in complex part production. Agile manufacturing emphasizes flexibility and rapid reconfiguration of production systems to meet varying customer demands and market changes efficiently. Choosing between adaptive machining and agile manufacturing depends on whether the priority is on precision in machining processes or overall production system responsiveness.

Connection

Adaptive machining leverages real-time data and machine learning algorithms to adjust cutting parameters dynamically, enhancing precision and reducing downtime. Agile manufacturing integrates flexible production systems and rapid response capabilities to meet changing market demands efficiently. The connection lies in their shared focus on flexibility and real-time responsiveness, enabling manufacturers to optimize processes and quickly adapt to product variations or supply chain disruptions.

Key Terms

Agile manufacturing:

Agile manufacturing emphasizes rapid responsiveness to market changes through flexible production processes, enabling companies to quickly adjust product designs and volumes while minimizing downtime. It leverages cross-functional teams and advanced technologies to enhance collaboration, reduce lead times, and optimize resource utilization in dynamic environments. Explore how agile manufacturing transforms operational efficiency and ensures competitive advantage in evolving industries.

Flexibility

Agile manufacturing emphasizes rapid response to market changes through modular processes and cross-functional teams, enhancing overall production flexibility. Adaptive machining incorporates real-time adjustments in machining parameters based on sensor feedback, enabling precise customization and efficient handling of variability in manufacturing. Explore these innovative approaches to flexibility in modern production for deeper insights.

Rapid response

Agile manufacturing emphasizes flexibility in production processes to quickly adjust to changing customer demands and market trends, leveraging modular designs and efficient workflow management. Adaptive machining integrates real-time data and smart technologies to modify machining parameters on the fly, enhancing precision and minimizing downtime during rapid response scenarios. Explore detailed comparisons to understand which approach best suits your manufacturing agility needs.

Source and External Links

What Is Agile Manufacturing? Lean vs. Agile - Agile manufacturing is a methodology focused on rapid response to customer demands, turning speed and agility into a competitive advantage, often building on lean manufacturing principles like small batch production and continuous improvement.

Agile Manufacturing: Benefits, Challenges, and Key Technologies - Agile manufacturing prioritizes responsiveness, speed, and customization, exemplified by Dell's model which eliminated inventory-heavy processes to achieve faster production cycles and higher quality while reducing costs.

Agile manufacturing - Wikipedia - Agile manufacturing enables companies to respond swiftly and flexibly to market changes by combining adaptability with cost and quality control, often integrating lean manufacturing to balance efficiency with flexibility.

dowidth.com

dowidth.com