Machine vision systems utilize cameras and image processing to detect defects and guide automation in manufacturing, enhancing quality control and operational efficiency. Artificial intelligence integrates machine learning algorithms to analyze complex data patterns, enable predictive maintenance, and optimize production workflows. Explore how combining machine vision and AI can revolutionize manufacturing processes and drive innovation.

Why it is important

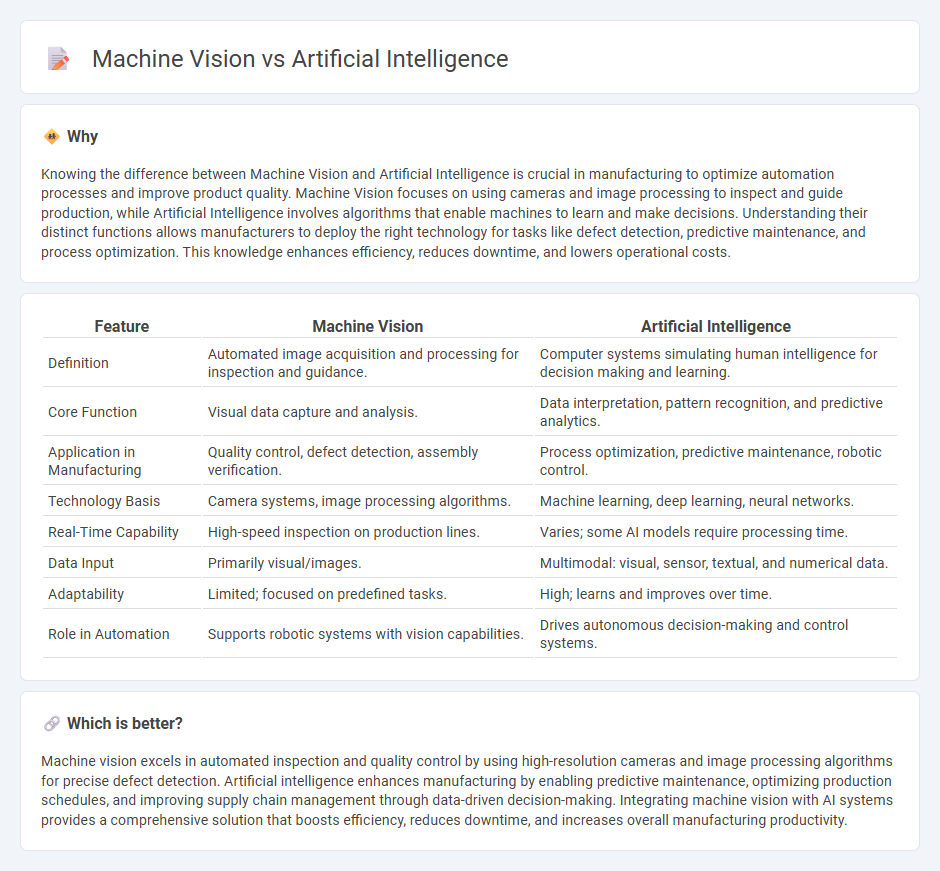

Knowing the difference between Machine Vision and Artificial Intelligence is crucial in manufacturing to optimize automation processes and improve product quality. Machine Vision focuses on using cameras and image processing to inspect and guide production, while Artificial Intelligence involves algorithms that enable machines to learn and make decisions. Understanding their distinct functions allows manufacturers to deploy the right technology for tasks like defect detection, predictive maintenance, and process optimization. This knowledge enhances efficiency, reduces downtime, and lowers operational costs.

Comparison Table

| Feature | Machine Vision | Artificial Intelligence |

|---|---|---|

| Definition | Automated image acquisition and processing for inspection and guidance. | Computer systems simulating human intelligence for decision making and learning. |

| Core Function | Visual data capture and analysis. | Data interpretation, pattern recognition, and predictive analytics. |

| Application in Manufacturing | Quality control, defect detection, assembly verification. | Process optimization, predictive maintenance, robotic control. |

| Technology Basis | Camera systems, image processing algorithms. | Machine learning, deep learning, neural networks. |

| Real-Time Capability | High-speed inspection on production lines. | Varies; some AI models require processing time. |

| Data Input | Primarily visual/images. | Multimodal: visual, sensor, textual, and numerical data. |

| Adaptability | Limited; focused on predefined tasks. | High; learns and improves over time. |

| Role in Automation | Supports robotic systems with vision capabilities. | Drives autonomous decision-making and control systems. |

Which is better?

Machine vision excels in automated inspection and quality control by using high-resolution cameras and image processing algorithms for precise defect detection. Artificial intelligence enhances manufacturing by enabling predictive maintenance, optimizing production schedules, and improving supply chain management through data-driven decision-making. Integrating machine vision with AI systems provides a comprehensive solution that boosts efficiency, reduces downtime, and increases overall manufacturing productivity.

Connection

Machine vision systems utilize artificial intelligence algorithms to analyze and interpret visual data in manufacturing processes, enabling real-time quality control and defect detection. AI-driven machine vision enhances automation by improving accuracy in identifying product anomalies and optimizing assembly line performance. Integration of deep learning models with machine vision accelerates predictive maintenance and reduces operational downtime in industrial manufacturing.

Key Terms

Automation

Artificial intelligence (AI) and machine vision are critical technologies in automation, with AI enabling machines to learn and make decisions based on data patterns, while machine vision uses cameras and image processing to interpret visual information. AI drives advanced automation by integrating data analysis, predictive maintenance, and robotics, whereas machine vision automates inspection, quality control, and defect detection in manufacturing. Explore the latest advancements in AI and machine vision to unlock the future potential of automation across industries.

Image Processing

Artificial intelligence and machine vision both leverage advanced image processing techniques, but AI utilizes deep learning algorithms to interpret complex patterns and make decisions, whereas machine vision primarily focuses on capturing and analyzing visual data for inspection and automation tasks. Machine vision systems excel in real-time image acquisition and defect detection in manufacturing, while AI enhances image recognition accuracy and adapts to evolving visual contexts. Explore our detailed insights to understand how AI and machine vision converge in transforming image processing applications.

Predictive Maintenance

Artificial intelligence enhances predictive maintenance by analyzing vast datasets to identify patterns and forecast equipment failures before they occur, improving operational efficiency and reducing downtime. Machine vision contributes by providing real-time visual inspections and defect detection, enabling precise monitoring of machinery conditions. Explore deeper insights into how AI and machine vision synergize to revolutionize predictive maintenance strategies.

Source and External Links

What Is Artificial Intelligence (AI)? | Google Cloud - Artificial intelligence is a technology that allows computers to perform advanced functions like image analysis and speech recognition by utilizing machine learning and deep learning.

Artificial Intelligence - Wikipedia - Artificial intelligence is the capability of computational systems to perform tasks typically associated with human intelligence, such as learning, reasoning, and decision-making.

Artificial Intelligence (AI): What it is and why it matters - SAS - Artificial intelligence makes it possible for machines to learn from experience and perform human-like tasks by combining data with iterative processing and intelligent algorithms.

dowidth.com

dowidth.com