Digital thread technology integrates data flow throughout the entire manufacturing lifecycle, enabling seamless traceability and real-time insights across design, production, and supply chain processes. ERP (Enterprise Resource Planning) systems centralize business functions such as inventory, finance, and human resources but lack the end-to-end vertical integration inherent in digital thread solutions. Explore how these technologies complement each other to optimize manufacturing efficiency and innovation.

Why it is important

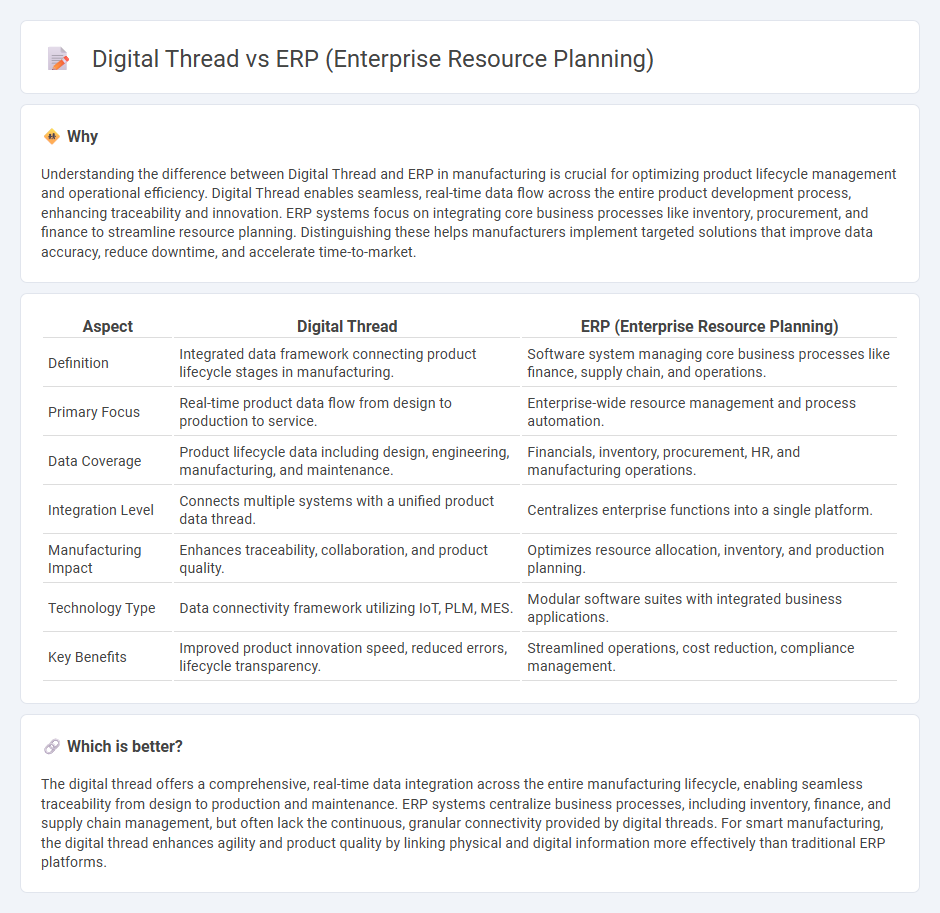

Understanding the difference between Digital Thread and ERP in manufacturing is crucial for optimizing product lifecycle management and operational efficiency. Digital Thread enables seamless, real-time data flow across the entire product development process, enhancing traceability and innovation. ERP systems focus on integrating core business processes like inventory, procurement, and finance to streamline resource planning. Distinguishing these helps manufacturers implement targeted solutions that improve data accuracy, reduce downtime, and accelerate time-to-market.

Comparison Table

| Aspect | Digital Thread | ERP (Enterprise Resource Planning) |

|---|---|---|

| Definition | Integrated data framework connecting product lifecycle stages in manufacturing. | Software system managing core business processes like finance, supply chain, and operations. |

| Primary Focus | Real-time product data flow from design to production to service. | Enterprise-wide resource management and process automation. |

| Data Coverage | Product lifecycle data including design, engineering, manufacturing, and maintenance. | Financials, inventory, procurement, HR, and manufacturing operations. |

| Integration Level | Connects multiple systems with a unified product data thread. | Centralizes enterprise functions into a single platform. |

| Manufacturing Impact | Enhances traceability, collaboration, and product quality. | Optimizes resource allocation, inventory, and production planning. |

| Technology Type | Data connectivity framework utilizing IoT, PLM, MES. | Modular software suites with integrated business applications. |

| Key Benefits | Improved product innovation speed, reduced errors, lifecycle transparency. | Streamlined operations, cost reduction, compliance management. |

Which is better?

The digital thread offers a comprehensive, real-time data integration across the entire manufacturing lifecycle, enabling seamless traceability from design to production and maintenance. ERP systems centralize business processes, including inventory, finance, and supply chain management, but often lack the continuous, granular connectivity provided by digital threads. For smart manufacturing, the digital thread enhances agility and product quality by linking physical and digital information more effectively than traditional ERP platforms.

Connection

The digital thread integrates data across the manufacturing lifecycle, ensuring real-time visibility from design to production and maintenance. ERP systems centralize enterprise-wide data, enabling seamless resource planning and operational efficiency. By connecting the digital thread with ERP, manufacturers achieve synchronized workflows, enhanced decision-making, and improved traceability throughout the supply chain.

Key Terms

Integration

ERP systems centralize business processes by integrating functions such as finance, supply chain, and human resources into a unified platform, enhancing data consistency across departments. The digital thread creates an end-to-end data flow by connecting product lifecycle stages from design to manufacturing, enabling real-time traceability and collaboration across systems. Explore how these integration strategies transform operational efficiency and decision-making by diving deeper into ERP and digital thread synergies.

Data continuity

ERP systems integrate core business processes by centralizing financial, inventory, and operational data, enabling streamlined workflows and real-time resource management. The digital thread creates an end-to-end data continuity loop across product lifecycles, linking design, manufacturing, and service information for enhanced traceability and decision-making. Explore how seamless data continuity through these technologies transforms enterprise efficiency and innovation.

Real-time visibility

ERP systems provide comprehensive integration of business processes, offering centralized data management but often with delayed updates across departments. Digital thread technology enables real-time visibility by seamlessly connecting product lifecycle information, supply chain status, and operational data, ensuring instant access to accurate insights for decision-making. Explore how the digital thread enhances enterprise efficiency beyond traditional ERP capabilities.

Source and External Links

Enterprise resource planning - Wikipedia - ERP is a category of business management software that integrates and manages core business processes in real time, using a centralized database to streamline operations across finance, manufacturing, HR, and more.

What is ERP? A Comprehensive Guide - NetSuite - ERP systems automate and centralize key business processes--such as accounting, inventory, sales, and HR--providing a unified view of company data to enhance efficiency, reduce errors, and support better decision-making.

What Is ERP? - Oracle - ERP software consolidates essential business tools (like finance, supply chain, and HR) into one system, with deployment options including on-premises, cloud-based, or hybrid models to suit different organizational needs.

dowidth.com

dowidth.com