Adaptive machining leverages real-time data and AI to customize manufacturing processes for each product, enhancing precision and reducing waste. Mass customization integrates flexible production techniques to deliver personalized products at scale, balancing efficiency with individual consumer demands. Explore how these innovative approaches are transforming modern manufacturing.

Why it is important

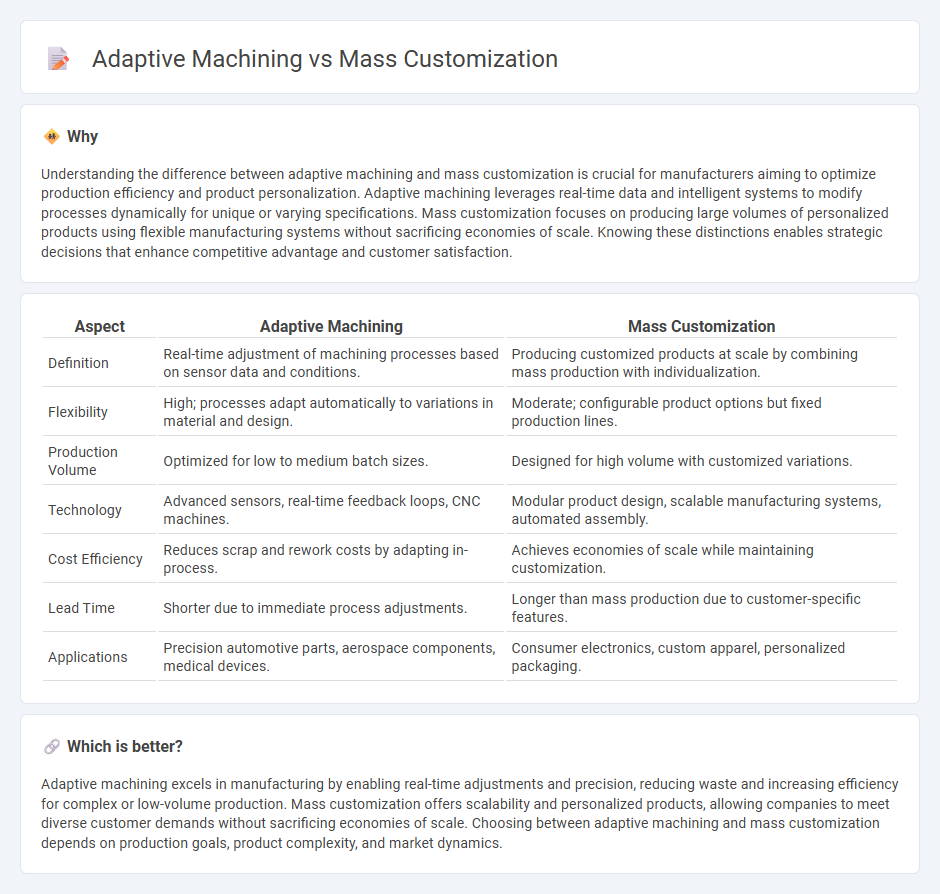

Understanding the difference between adaptive machining and mass customization is crucial for manufacturers aiming to optimize production efficiency and product personalization. Adaptive machining leverages real-time data and intelligent systems to modify processes dynamically for unique or varying specifications. Mass customization focuses on producing large volumes of personalized products using flexible manufacturing systems without sacrificing economies of scale. Knowing these distinctions enables strategic decisions that enhance competitive advantage and customer satisfaction.

Comparison Table

| Aspect | Adaptive Machining | Mass Customization |

|---|---|---|

| Definition | Real-time adjustment of machining processes based on sensor data and conditions. | Producing customized products at scale by combining mass production with individualization. |

| Flexibility | High; processes adapt automatically to variations in material and design. | Moderate; configurable product options but fixed production lines. |

| Production Volume | Optimized for low to medium batch sizes. | Designed for high volume with customized variations. |

| Technology | Advanced sensors, real-time feedback loops, CNC machines. | Modular product design, scalable manufacturing systems, automated assembly. |

| Cost Efficiency | Reduces scrap and rework costs by adapting in-process. | Achieves economies of scale while maintaining customization. |

| Lead Time | Shorter due to immediate process adjustments. | Longer than mass production due to customer-specific features. |

| Applications | Precision automotive parts, aerospace components, medical devices. | Consumer electronics, custom apparel, personalized packaging. |

Which is better?

Adaptive machining excels in manufacturing by enabling real-time adjustments and precision, reducing waste and increasing efficiency for complex or low-volume production. Mass customization offers scalability and personalized products, allowing companies to meet diverse customer demands without sacrificing economies of scale. Choosing between adaptive machining and mass customization depends on production goals, product complexity, and market dynamics.

Connection

Adaptive machining enhances mass customization by enabling precise adjustments in tooling and processes to meet unique product specifications. Real-time data integration in adaptive machining allows manufacturers to efficiently produce customized goods at scale without sacrificing quality. This synergy reduces lead times and improves flexibility, driving innovation in personalized manufacturing solutions.

Key Terms

Product Personalization

Mass customization allows products to be tailored to individual customer specifications on a large scale using modular design and flexible manufacturing systems. Adaptive machining utilizes real-time data and machine learning algorithms to dynamically modify machining processes ensuring highly precise and personalized product features. Discover how integrating these approaches can elevate product personalization in competitive markets.

Flexible Manufacturing Systems

Mass customization in Flexible Manufacturing Systems (FMS) enables the production of personalized products at near mass production efficiency by reconfiguring manufacturing processes rapidly. Adaptive machining enhances FMS by using real-time data and intelligent control systems to adjust machining parameters dynamically, improving precision and reducing waste. Explore how these advanced FMS approaches revolutionize manufacturing adaptability and efficiency.

Real-time Process Adjustment

Mass customization enables production of personalized products by adjusting manufacturing processes to individual specifications, leveraging flexible machinery and computerized control systems. Adaptive machining focuses on real-time process adjustment by using sensors and feedback loops to dynamically alter cutting parameters for enhanced accuracy and efficiency. Explore the innovations driving intelligent manufacturing and how these approaches optimize production workflows.

Source and External Links

Guide to Mass Customization - Mass customization combines personalized customization with the efficiency of mass production, using approaches like collaborative customization (co-creation) and adaptive customization to meet diverse customer needs effectively.

Mass Customization: A Complete Guide - It is a business strategy to deliver personalized products cost-effectively by understanding customer needs, leveraging technology, automation, and planning for scalability while ensuring quality control.

Mass customization - Mass customization uses flexible computer-aided systems to produce individually tailored products at near mass production costs, combining techniques like delayed differentiation and modular design for strategic and economic advantage.

dowidth.com

dowidth.com