Closed-loop manufacturing integrates real-time feedback systems to continuously monitor and adjust production processes, enhancing quality control and reducing waste. In contrast, open-loop manufacturing operates without such feedback, relying on predefined parameters and manual inspections, which can lead to higher variability and inefficiencies. Explore the advantages and applications of each approach to optimize your manufacturing strategy.

Why it is important

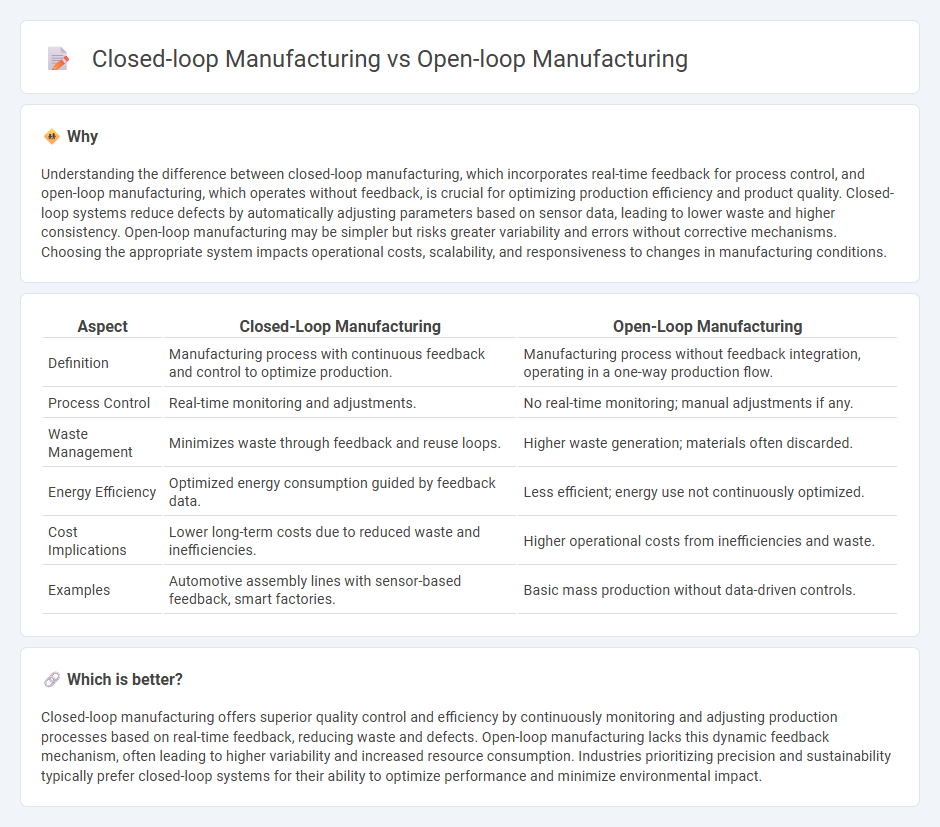

Understanding the difference between closed-loop manufacturing, which incorporates real-time feedback for process control, and open-loop manufacturing, which operates without feedback, is crucial for optimizing production efficiency and product quality. Closed-loop systems reduce defects by automatically adjusting parameters based on sensor data, leading to lower waste and higher consistency. Open-loop manufacturing may be simpler but risks greater variability and errors without corrective mechanisms. Choosing the appropriate system impacts operational costs, scalability, and responsiveness to changes in manufacturing conditions.

Comparison Table

| Aspect | Closed-Loop Manufacturing | Open-Loop Manufacturing |

|---|---|---|

| Definition | Manufacturing process with continuous feedback and control to optimize production. | Manufacturing process without feedback integration, operating in a one-way production flow. |

| Process Control | Real-time monitoring and adjustments. | No real-time monitoring; manual adjustments if any. |

| Waste Management | Minimizes waste through feedback and reuse loops. | Higher waste generation; materials often discarded. |

| Energy Efficiency | Optimized energy consumption guided by feedback data. | Less efficient; energy use not continuously optimized. |

| Cost Implications | Lower long-term costs due to reduced waste and inefficiencies. | Higher operational costs from inefficiencies and waste. |

| Examples | Automotive assembly lines with sensor-based feedback, smart factories. | Basic mass production without data-driven controls. |

Which is better?

Closed-loop manufacturing offers superior quality control and efficiency by continuously monitoring and adjusting production processes based on real-time feedback, reducing waste and defects. Open-loop manufacturing lacks this dynamic feedback mechanism, often leading to higher variability and increased resource consumption. Industries prioritizing precision and sustainability typically prefer closed-loop systems for their ability to optimize performance and minimize environmental impact.

Connection

Closed-loop manufacturing integrates real-time feedback and data analytics to constantly adjust and optimize production processes, enhancing precision and reducing waste. Open-loop manufacturing, while not self-correcting during operations, provides essential input data and initial parameters that inform the closed-loop system's adjustments. The connection lies in the iterative interaction where open-loop outputs guide closed-loop refinements, creating a dynamic cycle for improved manufacturing efficiency and quality.

Key Terms

Feedback

Open-loop manufacturing operates without real-time feedback, relying on pre-set processes and schedules, which can lead to inefficiencies and quality inconsistencies. Closed-loop manufacturing integrates continuous feedback from sensors and data analytics to dynamically adjust production parameters, enhancing precision and reducing waste. Discover how closed-loop systems revolutionize industrial productivity through advanced feedback integration.

Automation

Open-loop manufacturing relies on automated systems without direct feedback control, leading to potential inefficiencies and inconsistencies. Closed-loop manufacturing integrates sensors and real-time data analytics to continuously monitor and adjust processes, enhancing precision and reducing waste. Discover how advanced automation technologies are revolutionizing manufacturing workflows.

Real-time Data

Open-loop manufacturing relies on predefined processes without real-time feedback, often leading to delayed adjustments and inefficiencies. Closed-loop manufacturing leverages real-time data from sensors and IoT devices, enabling dynamic process control and immediate corrections to optimize production quality and reduce waste. Discover how integrating real-time data transforms manufacturing workflows for enhanced operational efficiency.

Source and External Links

Closed-Loop vs. Open-Loop Production Control - Open-loop manufacturing uses preset instructions without feedback, making it simple and low-cost but unable to adapt to output changes or process disruptions.

Understanding Open Loop Manufacturing Challenges - Open-loop systems lack real-time error correction, leading to delayed problem detection and longer improvement cycles compared to closed-loop systems.

The Essential Guide to Open Loop and Closed Loop Systems - Open-loop manufacturing is easier to design and maintain but offers no automatic adjustment based on output quality, relying instead on manual operator input.

dowidth.com

dowidth.com