Cobots, or collaborative robots, offer flexibility and ease of integration in manufacturing environments, enabling close human-robot interaction without extensive safety barriers. Fixed automation systems provide high-speed, high-volume production with precise control but lack adaptability to changing processes. Explore the advantages and applications of cobots versus fixed automation to determine the optimal solution for your manufacturing needs.

Why it is important

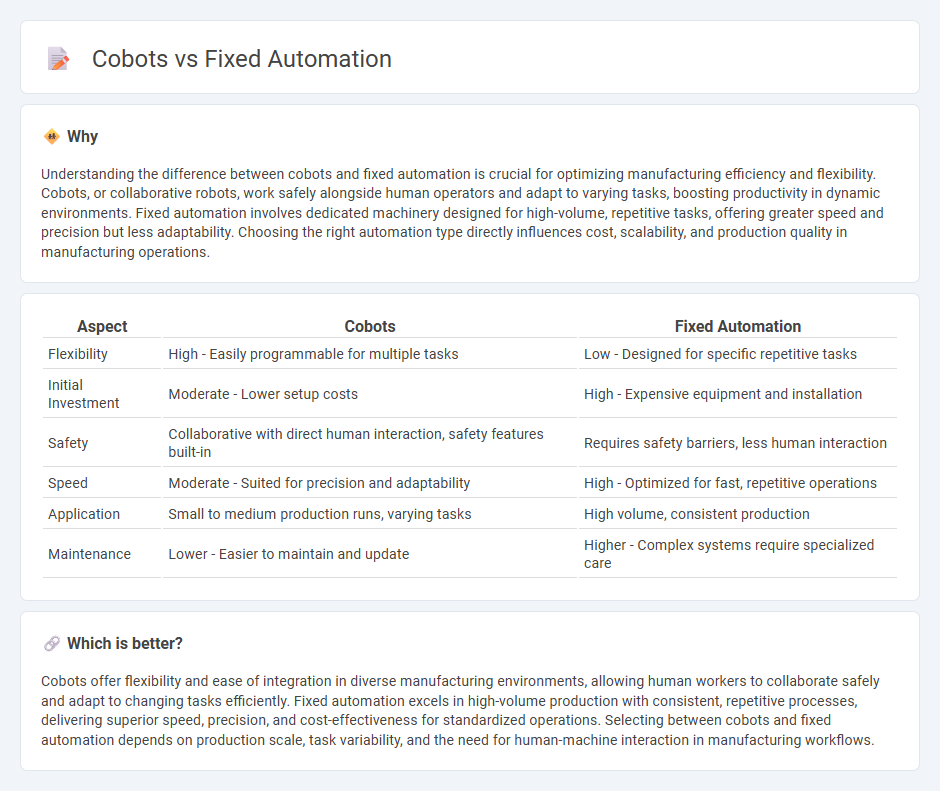

Understanding the difference between cobots and fixed automation is crucial for optimizing manufacturing efficiency and flexibility. Cobots, or collaborative robots, work safely alongside human operators and adapt to varying tasks, boosting productivity in dynamic environments. Fixed automation involves dedicated machinery designed for high-volume, repetitive tasks, offering greater speed and precision but less adaptability. Choosing the right automation type directly influences cost, scalability, and production quality in manufacturing operations.

Comparison Table

| Aspect | Cobots | Fixed Automation |

|---|---|---|

| Flexibility | High - Easily programmable for multiple tasks | Low - Designed for specific repetitive tasks |

| Initial Investment | Moderate - Lower setup costs | High - Expensive equipment and installation |

| Safety | Collaborative with direct human interaction, safety features built-in | Requires safety barriers, less human interaction |

| Speed | Moderate - Suited for precision and adaptability | High - Optimized for fast, repetitive operations |

| Application | Small to medium production runs, varying tasks | High volume, consistent production |

| Maintenance | Lower - Easier to maintain and update | Higher - Complex systems require specialized care |

Which is better?

Cobots offer flexibility and ease of integration in diverse manufacturing environments, allowing human workers to collaborate safely and adapt to changing tasks efficiently. Fixed automation excels in high-volume production with consistent, repetitive processes, delivering superior speed, precision, and cost-effectiveness for standardized operations. Selecting between cobots and fixed automation depends on production scale, task variability, and the need for human-machine interaction in manufacturing workflows.

Connection

Cobots and fixed automation integrate seamlessly to enhance manufacturing efficiency, where cobots provide flexible, human-robot collaboration while fixed automation delivers high-speed, repetitive task execution. Their connection allows for adaptive production lines combining precision with adaptability, optimizing throughput and reducing downtime. This synergy leverages sensor data and real-time communication protocols to synchronize operations, enabling smart factory environments.

Key Terms

Flexibility

Fixed automation systems offer high efficiency for repetitive tasks but lack adaptability in dynamic production environments. Cobots provide enhanced flexibility, working alongside human operators to adjust quickly to varying processes and product designs. Explore how integrating cobots can optimize your manufacturing flexibility and productivity.

Initial Investment

Fixed automation requires a higher initial investment due to custom machinery tailored for specific tasks, often leading to increased costs in design and setup. Cobots offer lower upfront expenses because they are flexible, easily programmable, and compatible with existing production lines, reducing the need for extensive infrastructure changes. Explore the key financial differences between fixed automation and cobots to make an informed decision for your manufacturing needs.

Human-Robot Collaboration

Fixed automation systems provide high-speed, repetitive task efficiency with minimal human intervention, ideal for mass production environments. Cobots, or collaborative robots, emphasize human-robot collaboration by working safely alongside workers to enhance flexibility and adaptability in various tasks. Explore more to understand how cobots revolutionize industrial processes through seamless teamwork.

Source and External Links

What is Fixed Automation? - GeeksforGeeks - Fixed automation is a manufacturing system that uses dedicated machinery to perform repetitive tasks quickly and precisely, ideal for high-volume production of a single product with consistent quality but limited flexibility.

Fixed Automation System: What It Is and Its Application in Manufacturing - Fixed automation refers to automated manufacturing where equipment is programmed for a single purpose, integrating all processes to reduce time and cost, commonly used in automotive, pharmaceutical, and assembly operations.

What Is Fixed Automation - Empowered Automation - Also known as rigid or hard automation, fixed automation produces a single product type with a set sequence determined by equipment configuration, offering limited flexibility but high efficiency in large-volume production.

dowidth.com

dowidth.com