The industrial metaverse integrates virtual reality, digital twins, and AI to create immersive, interactive manufacturing environments that enhance design, simulation, and real-time monitoring. Lean manufacturing focuses on minimizing waste and maximizing efficiency through continuous improvement practices like Just-In-Time production and value stream mapping. Explore how combining these concepts can revolutionize production processes and drive unprecedented operational excellence.

Why it is important

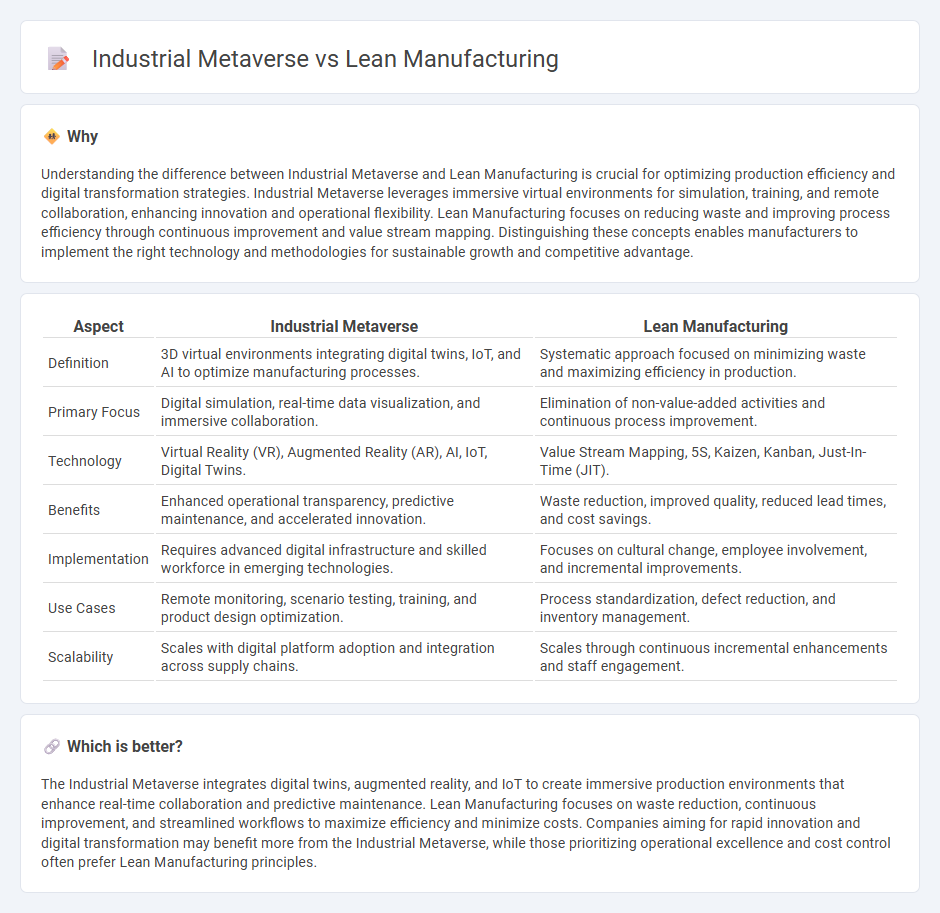

Understanding the difference between Industrial Metaverse and Lean Manufacturing is crucial for optimizing production efficiency and digital transformation strategies. Industrial Metaverse leverages immersive virtual environments for simulation, training, and remote collaboration, enhancing innovation and operational flexibility. Lean Manufacturing focuses on reducing waste and improving process efficiency through continuous improvement and value stream mapping. Distinguishing these concepts enables manufacturers to implement the right technology and methodologies for sustainable growth and competitive advantage.

Comparison Table

| Aspect | Industrial Metaverse | Lean Manufacturing |

|---|---|---|

| Definition | 3D virtual environments integrating digital twins, IoT, and AI to optimize manufacturing processes. | Systematic approach focused on minimizing waste and maximizing efficiency in production. |

| Primary Focus | Digital simulation, real-time data visualization, and immersive collaboration. | Elimination of non-value-added activities and continuous process improvement. |

| Technology | Virtual Reality (VR), Augmented Reality (AR), AI, IoT, Digital Twins. | Value Stream Mapping, 5S, Kaizen, Kanban, Just-In-Time (JIT). |

| Benefits | Enhanced operational transparency, predictive maintenance, and accelerated innovation. | Waste reduction, improved quality, reduced lead times, and cost savings. |

| Implementation | Requires advanced digital infrastructure and skilled workforce in emerging technologies. | Focuses on cultural change, employee involvement, and incremental improvements. |

| Use Cases | Remote monitoring, scenario testing, training, and product design optimization. | Process standardization, defect reduction, and inventory management. |

| Scalability | Scales with digital platform adoption and integration across supply chains. | Scales through continuous incremental enhancements and staff engagement. |

Which is better?

The Industrial Metaverse integrates digital twins, augmented reality, and IoT to create immersive production environments that enhance real-time collaboration and predictive maintenance. Lean Manufacturing focuses on waste reduction, continuous improvement, and streamlined workflows to maximize efficiency and minimize costs. Companies aiming for rapid innovation and digital transformation may benefit more from the Industrial Metaverse, while those prioritizing operational excellence and cost control often prefer Lean Manufacturing principles.

Connection

Industrial metaverse leverages digital twin technology and immersive simulations to optimize Lean Manufacturing processes by visualizing workflows and identifying waste in real-time. Integration of IoT sensors and AI analytics within the industrial metaverse enables continuous improvement by monitoring key performance indicators (KPIs) and streamlining value streams. This synergy enhances operational efficiency, reduces production lead times, and drives sustainable manufacturing practices.

Key Terms

Waste Reduction (Lean Manufacturing)

Lean Manufacturing emphasizes waste reduction by streamlining processes and eliminating non-value-added activities, significantly improving operational efficiency and cost savings. The Industrial Metaverse leverages digital twins and immersive simulations to identify and minimize waste in real-time, enhancing predictive maintenance and resource usage. Explore how combining Lean Manufacturing principles with Industrial Metaverse technologies can revolutionize waste reduction strategies in modern industries.

Digital Twin (Industrial Metaverse)

Lean Manufacturing enhances production efficiency by minimizing waste and optimizing workflows, relying on principles like Just-In-Time and continuous improvement. The Industrial Metaverse leverages Digital Twin technology to create real-time, interactive virtual replicas of physical assets, enabling predictive maintenance, remote monitoring, and advanced simulations. Explore how integrating Digital Twins within Lean Manufacturing frameworks transforms industrial processes through data-driven insights and immersive digital environments.

Continuous Improvement (Lean Manufacturing)

Lean Manufacturing emphasizes continuous improvement through waste reduction, process optimization, and employee empowerment to enhance operational efficiency. The Industrial Metaverse integrates advanced digital technologies like IoT, AI, and AR to create immersive environments that enable real-time monitoring, predictive maintenance, and collaborative problem-solving, augmenting lean principles. Explore deeper how these approaches converge to drive innovation and sustainable productivity in modern manufacturing.

Source and External Links

Lean manufacturing - Lean manufacturing is a method focused on reducing production and response times by eliminating waste that does not add customer value, based on the Toyota Production System and including the seven wastes such as overproduction and defective products.

What is Lean Manufacturing? | Definition from TechTarget - It is a methodology aimed at minimizing waste and maximizing productivity by applying principles like Kaizen, with origins in Toyota's system and applications beyond manufacturing, including healthcare and software development.

Understanding a New Manufacturing System - Lean manufacturing promotes worker participation, multi-skilled teams, continuous improvement, and quality control to reduce inventory costs and production errors, differing from traditional Fordist manufacturing.

dowidth.com

dowidth.com