Condition-based monitoring leverages real-time data from sensors to assess equipment health and predict failures, enabling timely interventions and minimizing downtime. Reliability-centered maintenance focuses on maintaining system functionality by prioritizing maintenance tasks based on risk and criticality to optimize resource allocation. Explore the differences to determine which strategy best enhances your manufacturing operations.

Why it is important

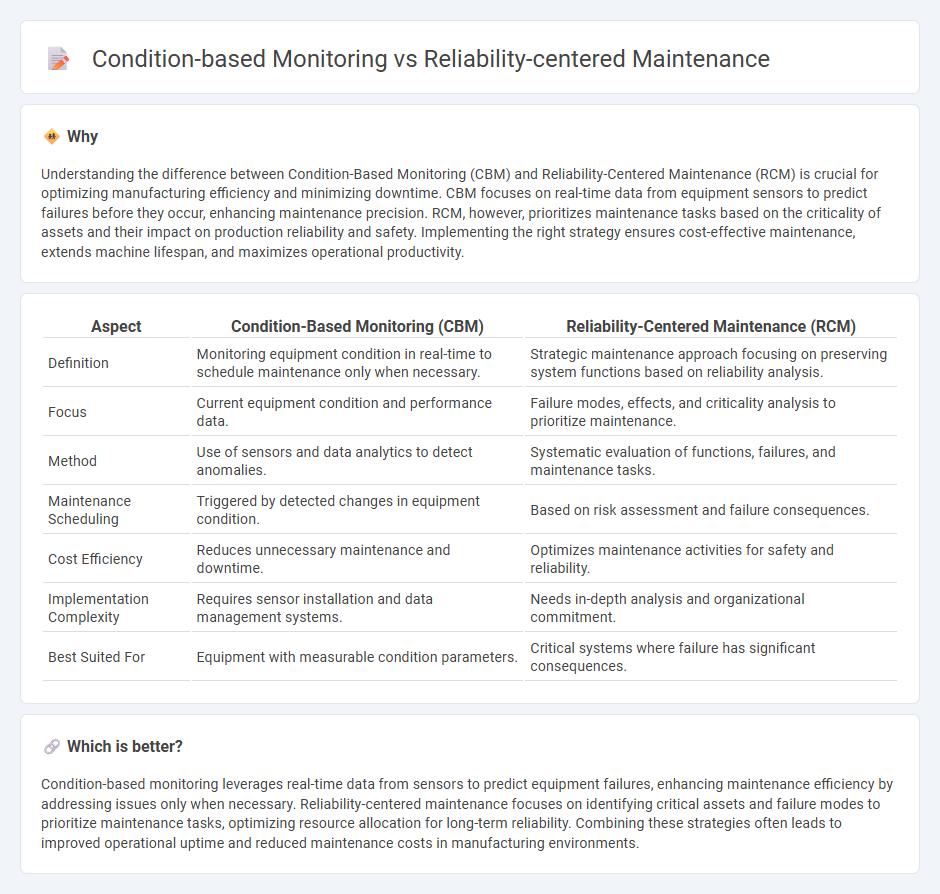

Understanding the difference between Condition-Based Monitoring (CBM) and Reliability-Centered Maintenance (RCM) is crucial for optimizing manufacturing efficiency and minimizing downtime. CBM focuses on real-time data from equipment sensors to predict failures before they occur, enhancing maintenance precision. RCM, however, prioritizes maintenance tasks based on the criticality of assets and their impact on production reliability and safety. Implementing the right strategy ensures cost-effective maintenance, extends machine lifespan, and maximizes operational productivity.

Comparison Table

| Aspect | Condition-Based Monitoring (CBM) | Reliability-Centered Maintenance (RCM) |

|---|---|---|

| Definition | Monitoring equipment condition in real-time to schedule maintenance only when necessary. | Strategic maintenance approach focusing on preserving system functions based on reliability analysis. |

| Focus | Current equipment condition and performance data. | Failure modes, effects, and criticality analysis to prioritize maintenance. |

| Method | Use of sensors and data analytics to detect anomalies. | Systematic evaluation of functions, failures, and maintenance tasks. |

| Maintenance Scheduling | Triggered by detected changes in equipment condition. | Based on risk assessment and failure consequences. |

| Cost Efficiency | Reduces unnecessary maintenance and downtime. | Optimizes maintenance activities for safety and reliability. |

| Implementation Complexity | Requires sensor installation and data management systems. | Needs in-depth analysis and organizational commitment. |

| Best Suited For | Equipment with measurable condition parameters. | Critical systems where failure has significant consequences. |

Which is better?

Condition-based monitoring leverages real-time data from sensors to predict equipment failures, enhancing maintenance efficiency by addressing issues only when necessary. Reliability-centered maintenance focuses on identifying critical assets and failure modes to prioritize maintenance tasks, optimizing resource allocation for long-term reliability. Combining these strategies often leads to improved operational uptime and reduced maintenance costs in manufacturing environments.

Connection

Condition-based monitoring enables real-time data collection on equipment performance, which directly informs Reliability-centered maintenance strategies by identifying critical assets and predicting failure modes. This integration optimizes maintenance scheduling, reduces downtime, and extends machinery lifespan. Leveraging sensor data and predictive analytics enhances operational efficiency and supports informed decision-making in manufacturing environments.

Key Terms

Failure Modes and Effects Analysis (FMEA)

Reliability-centered maintenance (RCM) prioritizes systematic failure analysis through Failure Modes and Effects Analysis (FMEA) to optimize asset performance and safety by identifying critical failure modes and determining appropriate maintenance strategies. Condition-based monitoring (CBM) relies on real-time data from sensors and diagnostics to detect deviations from normal operating conditions, enabling predictive maintenance before failure occurs but may lack the comprehensive fault consequence evaluation that FMEA provides. Explore the advantages and integration of RCM and CBM with FMEA for enhanced maintenance decision-making.

Predictive Analytics

Reliability-centered maintenance (RCM) prioritizes optimizing asset reliability through systematic failure analysis, while condition-based monitoring (CBM) employs real-time data from sensors to assess equipment health and predict failures. Predictive analytics in CBM leverages machine learning algorithms and historical data patterns to forecast maintenance needs, reducing unplanned downtime more effectively than traditional RCM. Explore how integrating advanced predictive analytics can transform maintenance strategies and enhance operational efficiency.

Preventive Maintenance

Reliability-centered maintenance (RCM) prioritizes identifying critical assets and failure modes to develop preventive maintenance strategies that ensure system reliability and safety. Condition-based monitoring (CBM) uses real-time data from sensors to detect asset deterioration, enabling targeted preventive actions that reduce unnecessary maintenance. Explore the key differences and benefits of each approach to optimize your preventive maintenance program.

Source and External Links

Reliability-Centered Maintenance (RCM) - RCM integrates reactive, time-based, condition-based, and proactive maintenance practices to maximize equipment reliability while minimizing life-cycle costs by understanding system functions and failure modes.

Reliability-Centered Maintenance: What It Is & How ... - RCM is a preventative maintenance strategy focusing on identifying and preventing failure modes to optimize reliability, reduce downtime, and deliver cost-effective asset management.

Condition-Based vs Reliability-Centered Maintenance - RCM is a comprehensive and strategic approach that considers asset criticality and functions within a system, going beyond condition monitoring to optimize maintenance policies.

dowidth.com

dowidth.com