Human augmentation enhances worker capabilities through wearable exoskeletons and neural interfaces, boosting productivity and safety on manufacturing floors. Digital twin technology creates precise virtual replicas of physical assets, enabling real-time monitoring, predictive maintenance, and process optimization. Explore how integrating these innovations can revolutionize manufacturing efficiency and workforce dynamics.

Why it is important

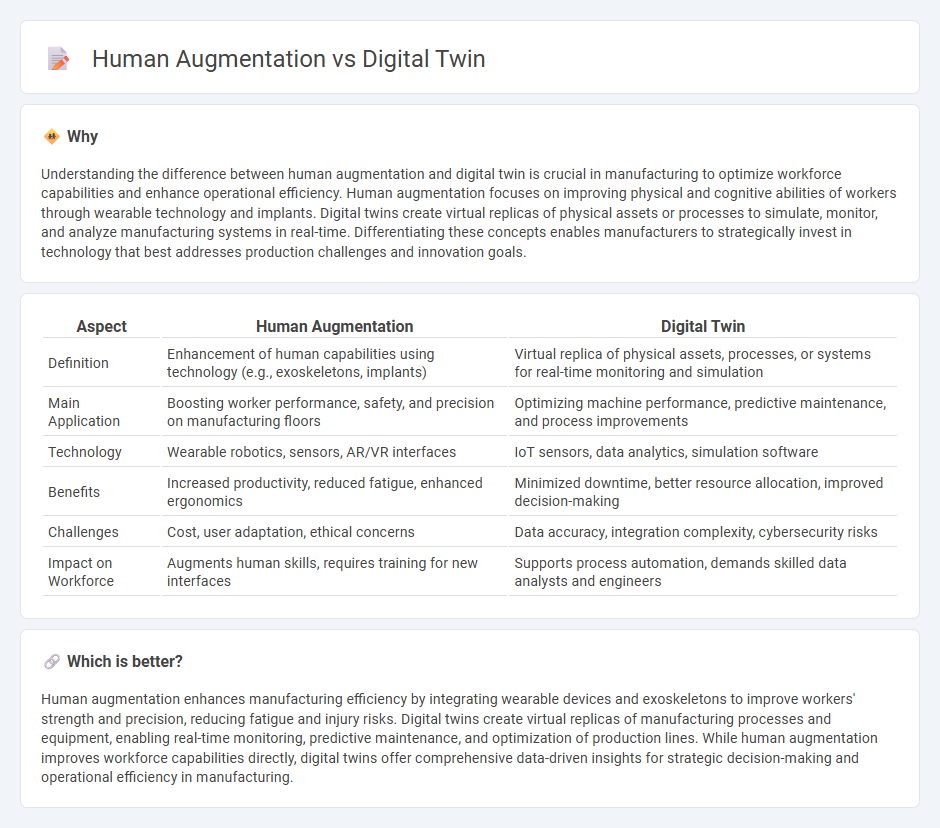

Understanding the difference between human augmentation and digital twin is crucial in manufacturing to optimize workforce capabilities and enhance operational efficiency. Human augmentation focuses on improving physical and cognitive abilities of workers through wearable technology and implants. Digital twins create virtual replicas of physical assets or processes to simulate, monitor, and analyze manufacturing systems in real-time. Differentiating these concepts enables manufacturers to strategically invest in technology that best addresses production challenges and innovation goals.

Comparison Table

| Aspect | Human Augmentation | Digital Twin |

|---|---|---|

| Definition | Enhancement of human capabilities using technology (e.g., exoskeletons, implants) | Virtual replica of physical assets, processes, or systems for real-time monitoring and simulation |

| Main Application | Boosting worker performance, safety, and precision on manufacturing floors | Optimizing machine performance, predictive maintenance, and process improvements |

| Technology | Wearable robotics, sensors, AR/VR interfaces | IoT sensors, data analytics, simulation software |

| Benefits | Increased productivity, reduced fatigue, enhanced ergonomics | Minimized downtime, better resource allocation, improved decision-making |

| Challenges | Cost, user adaptation, ethical concerns | Data accuracy, integration complexity, cybersecurity risks |

| Impact on Workforce | Augments human skills, requires training for new interfaces | Supports process automation, demands skilled data analysts and engineers |

Which is better?

Human augmentation enhances manufacturing efficiency by integrating wearable devices and exoskeletons to improve workers' strength and precision, reducing fatigue and injury risks. Digital twins create virtual replicas of manufacturing processes and equipment, enabling real-time monitoring, predictive maintenance, and optimization of production lines. While human augmentation improves workforce capabilities directly, digital twins offer comprehensive data-driven insights for strategic decision-making and operational efficiency in manufacturing.

Connection

Human augmentation enhances worker capabilities through wearable devices and exoskeletons, while digital twins create virtual replicas of physical systems for real-time monitoring. Integrating these technologies allows manufacturers to optimize human-machine interaction, improve safety, and increase productivity by simulating and analyzing both human performance and equipment behavior. This synergy supports predictive maintenance, personalized training, and adaptive automation within smart factories.

Key Terms

Simulation

Digital twins create precise virtual models of physical systems for real-time simulation and performance analysis, enabling predictive maintenance and optimization. Human augmentation enhances cognitive and physical abilities through wearable devices or implants, often relying on simulations to improve interaction and adaptability. Explore how these technologies leverage simulation to transform industry and healthcare applications.

Cyber-physical Systems

Digital twins in cyber-physical systems replicate physical entities through real-time data integration, enabling predictive maintenance and system optimization. Human augmentation enhances physical and cognitive capabilities via wearable technologies and neural interfaces, directly impacting human interaction with cyber-physical environments. Explore deeper insights into how these technologies reshape industrial and human-centric applications.

Wearable Technology

Wearable technology in digital twin systems creates precise virtual replicas of physical entities, enabling real-time data monitoring and predictive maintenance. Human augmentation devices enhance users' physical and cognitive abilities through sensors and interactive interfaces, improving productivity and health outcomes. Explore how these innovations intersect to revolutionize industries and personal wellness.

Source and External Links

What Is a Digital Twin? - IBM - A digital twin is a virtual representation of an object or system designed to accurately reflect a physical object using real-time data and simulations for analysis and improvement.

Definition of a Digital Twin - Digital Twin Consortium - A digital twin is an integrated, data-driven virtual replica of real-world entities and processes, synchronized with its physical counterpart for improved understanding and decision-making.

Digital twin - Wikipedia - A digital twin is a digital model of a real-world product, system, or process that serves as a counterpart for simulation, testing, monitoring, and maintenance throughout its lifecycle.

dowidth.com

dowidth.com