Digital thread integrates data flow across the entire manufacturing lifecycle, enabling seamless information exchange between design, production, and maintenance phases. Digital twin creates a virtual replica of physical assets, facilitating real-time monitoring, simulation, and predictive analytics to optimize performance. Explore the differences and benefits of digital thread and digital twin to enhance manufacturing efficiency.

Why it is important

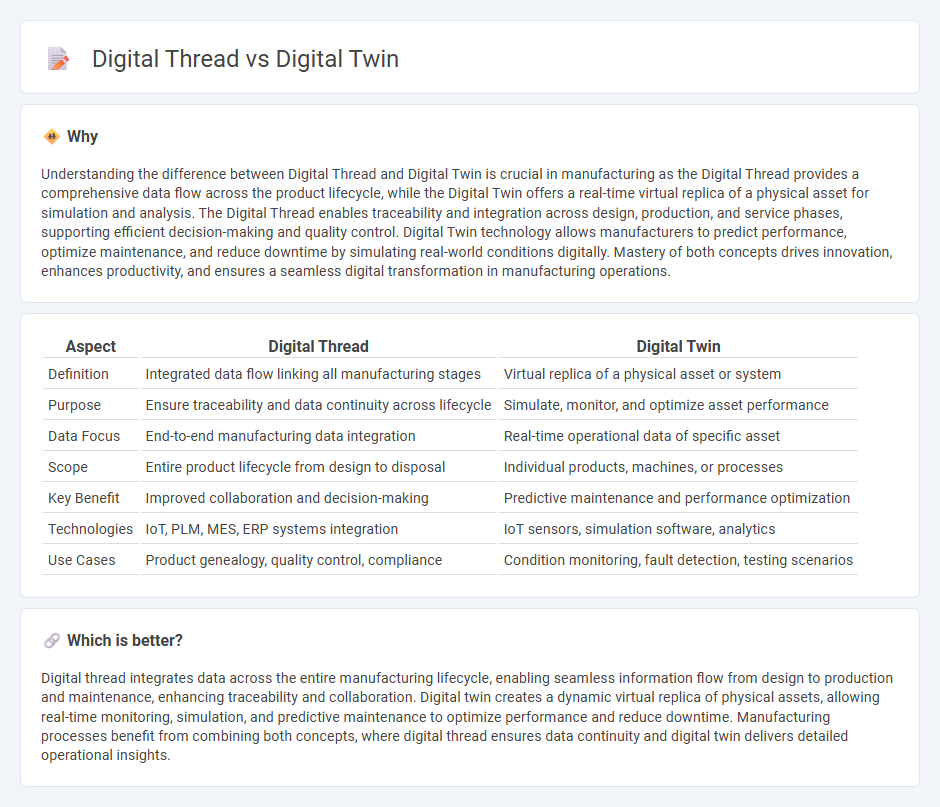

Understanding the difference between Digital Thread and Digital Twin is crucial in manufacturing as the Digital Thread provides a comprehensive data flow across the product lifecycle, while the Digital Twin offers a real-time virtual replica of a physical asset for simulation and analysis. The Digital Thread enables traceability and integration across design, production, and service phases, supporting efficient decision-making and quality control. Digital Twin technology allows manufacturers to predict performance, optimize maintenance, and reduce downtime by simulating real-world conditions digitally. Mastery of both concepts drives innovation, enhances productivity, and ensures a seamless digital transformation in manufacturing operations.

Comparison Table

| Aspect | Digital Thread | Digital Twin |

|---|---|---|

| Definition | Integrated data flow linking all manufacturing stages | Virtual replica of a physical asset or system |

| Purpose | Ensure traceability and data continuity across lifecycle | Simulate, monitor, and optimize asset performance |

| Data Focus | End-to-end manufacturing data integration | Real-time operational data of specific asset |

| Scope | Entire product lifecycle from design to disposal | Individual products, machines, or processes |

| Key Benefit | Improved collaboration and decision-making | Predictive maintenance and performance optimization |

| Technologies | IoT, PLM, MES, ERP systems integration | IoT sensors, simulation software, analytics |

| Use Cases | Product genealogy, quality control, compliance | Condition monitoring, fault detection, testing scenarios |

Which is better?

Digital thread integrates data across the entire manufacturing lifecycle, enabling seamless information flow from design to production and maintenance, enhancing traceability and collaboration. Digital twin creates a dynamic virtual replica of physical assets, allowing real-time monitoring, simulation, and predictive maintenance to optimize performance and reduce downtime. Manufacturing processes benefit from combining both concepts, where digital thread ensures data continuity and digital twin delivers detailed operational insights.

Connection

Digital thread creates a continuous flow of data throughout the manufacturing lifecycle, enabling real-time integration of design, production, and performance information. Digital twin uses this data to generate a virtual replica of physical assets, processes, or systems for simulation, monitoring, and optimization. Together, they enhance predictive maintenance, quality control, and operational efficiency by connecting physical and digital environments seamlessly.

Key Terms

Simulation

Digital twin technology offers real-time simulation of physical assets by creating virtual replicas that monitor and predict performance under varying conditions. Digital thread integrates data flow across the product lifecycle, enabling seamless simulation updates through continuous information exchange between design, manufacturing, and operation stages. Explore how combining digital twins and digital threads enhances simulation accuracy and decision-making in complex systems.

Data integration

Digital twin technology creates a dynamic virtual model of a physical asset, continuously integrating real-time data to simulate performance and predict outcomes. Digital thread connects data throughout the entire product lifecycle, ensuring seamless information flow from design to manufacturing to service, enabling comprehensive traceability and collaboration. Explore how these data integration approaches enhance operational efficiency and decision-making in complex systems.

Lifecycle management

Digital twin technology creates a real-time virtual model of a physical asset, enabling precise monitoring and predictive maintenance throughout its lifecycle. Digital thread integrates comprehensive data flow across different lifecycle stages, connecting design, production, and operation to ensure seamless information continuity and traceability. Explore detailed comparisons and applications to optimize lifecycle management strategies in advanced manufacturing.

Source and External Links

Definition of a Digital Twin - A digital twin is an integrated, data-driven virtual representation of real-world entities and processes, synchronized with the physical counterpart at a specified frequency and fidelity to enable continuous understanding, improvement, and decision-making.

What Is a Digital Twin? - A digital twin is a virtual model of a physical object or system, continuously updated with real-time data to simulate, analyze, and optimize the physical entity's performance throughout its lifecycle.

Digital twin - A digital twin is a set of adaptive digital models that emulate the behavior of a physical system, using real-time data for simulation, monitoring, maintenance, and predictive analysis.

dowidth.com

dowidth.com